Table of Contents

Introduction

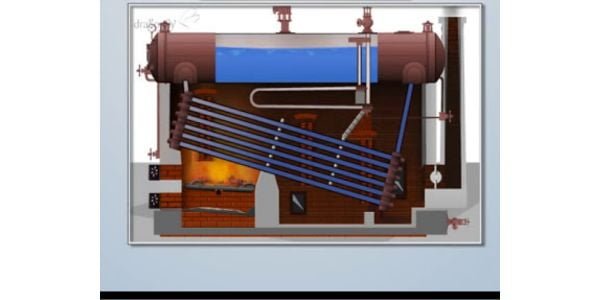

The Babcock and Wilcox boiler, also known as the B&W boiler, is a widely used water tube boiler in the power generation and industrial sectors. Invented by George Herman Babcock and Stephen Wilcox in the 19th century, this boiler design revolutionized steam power plants. It is renowned for its durability, efficiency, and ability to handle high-pressure steam.

Definition of Babcock and Wilcox Boiler

The Babcock and Wilcox boiler is a water tube boiler that operates with high-pressure steam. It consists of water tubes arranged in a triangular shape, which allows for efficient heat transfer. The boiler’s design facilitates the generation of large quantities of steam and provides excellent control over its quality and circulation.

Parts of Babcock and Wilcox Boiler

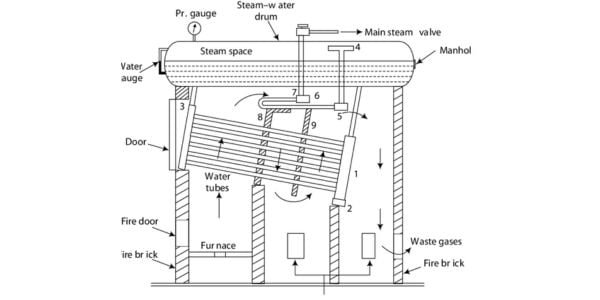

1. Water Drum: The water drum is a large cylindrical vessel located at the bottom of the boiler. It stores water and serves as a reservoir for steam generation.

2. Mud Drum: The mud drum is another cylindrical vessel positioned at the bottom of the furnace. It collects sediments and impurities from the water, preventing them from entering the main steam drum.

3. Steam Drum: The steam drum is a horizontal cylindrical vessel situated above the water drum. It stores steam generated in the boiler before it is sent to the superheater for further heating.

4. Water Tubes: These are inclined or curved tubes that connect the water drum and steam drum. Water flows through these tubes, absorbing heat from the combustion gases.

5. Uptake Header and Downcomer: The uptake header collects the steam-water mixture from the water tubes and delivers it to the steam drum. The downcomer is a pipe that transports water from the steam drum to the water drum.

6. Superheater: The superheater is a heat exchanger located in the path of flue gases. It raises the temperature of the steam, increasing its thermal energy and overall efficiency.

7. Furnace: The furnace is the combustion chamber where fuel is burned to generate heat. It is typically located below the water tubes and is lined with refractory materials to withstand high temperatures.

8. Grate: The grate is a metal platform or framework situated inside the furnace. It supports the fuel bed and allows for the proper combustion of solid fuels.

9. Chimney: The chimney provides an outlet for the flue gases and maintains the required draft for efficient combustion. It creates a pressure difference, facilitating the removal of combustion products.

Working Principle of Babcock and Wilcox Boiler

The Babcock and Wilcox boiler operates on the principle of forced circulation. The water is supplied to the water drum, and through the downcomer, it reaches the mud drum. From the mud drum, it enters the inclined water tubes situated in the furnace.

The fuel, such as coal or oil, is burned in the furnace, generating hot combustion gases. These gases flow over the water tubes, transferring heat to the circulating water. As the water absorbs heat, it undergoes partial evaporation and rises to the steam drum through the uptake header.

In the steam drum, the steam and water mixture is separated. The steam is then sent to the superheater, where it gains additional heat and becomes superheated steam. The superheated steam can be used for various industrial applications or sent to a turbine for power generation.

Meanwhile, the water, which has lost heat, descends through the downcomer and returns to the water drum. This circulation process is maintained continuously, ensuring a steady supply of steam.

Advantages of Babcock and Wilcox Boiler

1. High Efficiency:

The Babcock and Wilcox boiler exhibits high thermal efficiency due to its efficient water tube design. The large heating surface area and the ability to use multiple fuel types, such as coal, oil, and gas, contribute to its exceptional efficiency. This results in optimal heat transfer and maximum steam generation.

2. Ability to Handle High Pressure and Temperature:

The Babcock and Wilcox boiler is renowned for its capability to operate at high pressures and temperatures. This makes it suitable for applications that require the production of superheated steam, such as power generation in steam turbines and industrial processes that demand high-temperature steam.

3. Reliable and Robust Construction:

The boiler’s construction, comprising strong and durable materials, ensures its reliability and longevity. The use of high-quality steel and robust design principles allows the boiler to withstand high pressures and temperature fluctuations, minimizing the risk of accidents or failures.

4. Flexibility in Fuel Choice:

The Babcock and Wilcox boiler offers flexibility in terms of fuel selection. It can efficiently burn a wide range of solid, liquid, and gaseous fuels, providing versatility to industries with varying fuel availability and preferences. This adaptability contributes to its widespread use across different sectors.

5. Excellent Control over Steam Quality:

The water tube design of the Babcock and Wilcox boiler enables better control over steam quality. The separation of steam and water in the steam drum ensures that only dry, high-quality steam is delivered for industrial processes or power generation. This control is crucial for applications where steam quality is a critical factor.

Applications of Babcock and Wilcox Boiler

1. Power Generation:

The Babcock and Wilcox boiler finds extensive use in power plants for electricity generation. Its ability to generate large quantities of high-pressure steam makes it ideal for driving steam turbines, which convert the thermal energy of steam into mechanical energy to generate electricity.

2. Industrial Processes:

Various industrial sectors benefit from the Babcock and Wilcox boiler’s capabilities. Industries such as chemical, petrochemical, textile, paper, and food processing rely on the boiler for processes requiring high-temperature steam. These applications include heat exchangers, steam-driven machinery, sterilization, and drying operations.

3. Marine Applications:

The Babcock and Wilcox boiler has a significant presence in the marine industry. It provides steam power for propulsion systems in ships and vessels. The boiler’s ability to operate efficiently under high pressures and temperatures makes it suitable for marine environments where reliable and robust power generation is crucial.

4. Heating and District Heating:

The Babcock and Wilcox boiler can also be used for heating purposes in residential, commercial, and industrial settings. It can provide hot water or steam for space heating, district heating networks, and other applications requiring centralized heating systems.

Also, read Shaper Machine

Comment on “Babcock and Wilcox boiler – Defenition, Working, Application”

Comments are closed.