Table of Contents

What is a Remote Terminal Unit (RTU)?

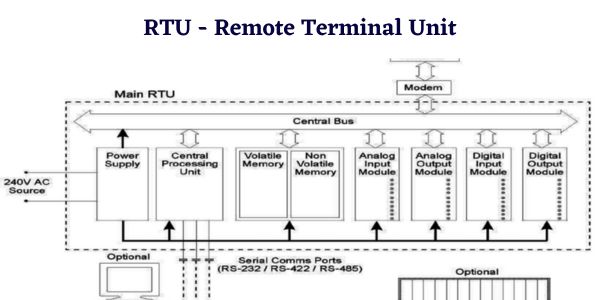

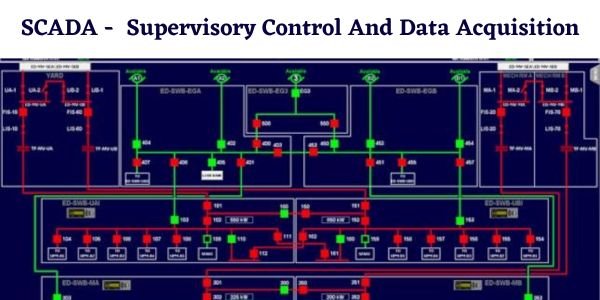

A Remote Terminal Unit (RTU) is a device used in SCADA systems for monitoring and controlling remote equipment. It is installed in the field or remote location, and it collects data from sensors, meters, and other devices that are connected to it. The RTU then processes this data and transmits it back to a central control room where it is used to make decisions about the operation of the equipment.

The RTU is typically a ruggedized device designed to withstand harsh environmental conditions. It has an embedded microprocessor, memory, and communication interfaces for connecting to the sensors and the central control room. It can also have built-in alarm and event detection capabilities, which can trigger alarms and send notifications to operators in the control room.

Functions of a Remote Terminal Unit (RTU)

RTUs are designed to perform several functions, some of which are as follows:

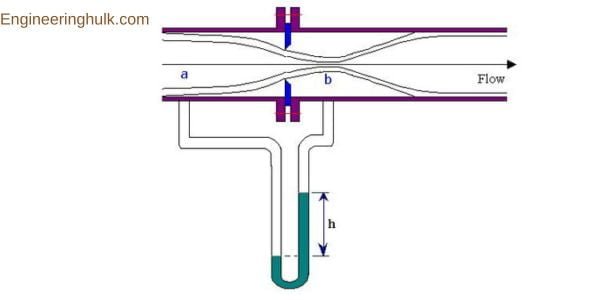

Data acquisition: RTUs collect data from sensors and other devices in the field. They can measure physical parameters such as temperature, pressure, and flow rate.

Data processing: The data collected by the RTU is processed to generate meaningful information. The RTU can perform calculations, data logging, and data filtering.

Communication: The RTU communicates with the central control room using various communication interfaces such as Ethernet, RS232, RS485, or wireless communication.

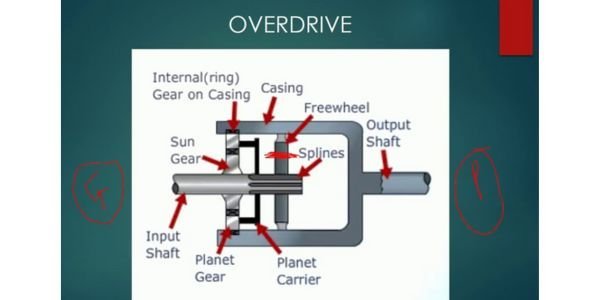

Control: The RTU can also be used for controlling the equipment in the field. For example, it can open or close valves, start or stop pumps, or change the setpoints of controllers.

Event detection: RTUs can detect events such as power outages, equipment failures, and abnormal operating conditions. They can trigger alarms and send notifications to the operators in the control room.

Importance of RTU in Industrial Automation

RTUs play a critical role in industrial automation by providing real-time data about the operation of equipment in the field. This data is used by operators in the control room to make informed decisions about the operation of the equipment. Some of the benefits of using RTUs in industrial automation include:

Improved efficiency: RTUs provide real-time data about the operation of equipment, which allows operators to make informed decisions about its operation. This leads to improved efficiency and reduced downtime.

Improved safety: RTUs can detect abnormal operating conditions and trigger alarms to alert operators in the control room. This helps to improve safety and prevent accidents.

Reduced maintenance costs: RTUs can detect equipment failures and send notifications to the maintenance team. This allows for proactive maintenance, which can reduce maintenance costs and downtime.

Improved data accuracy: RTUs collect data directly from the field, which reduces the risk of human error. This leads to improved data accuracy and better decision-making.

Remote Terminal Units (RTUs) are essential devices in industrial automation. They provide real-time data about the operation of equipment in the field, which allows operators in the control room to make informed decisions about its operation.

RTUs are designed to be rugged and can withstand harsh environmental conditions. They perform several functions such as data acquisition, data processing, communication, control, and event detection. The use of RTUs in industrial automation leads to improved efficiency, safety, reduced maintenance costs, and improved data accuracy.

Comment on “RTU – Remote Terminal Unit Definition, Functions, Importance”

Comments are closed.