Table of Contents

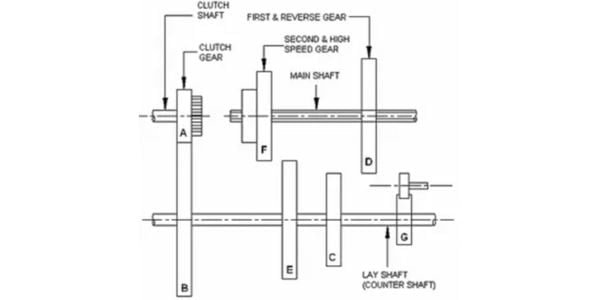

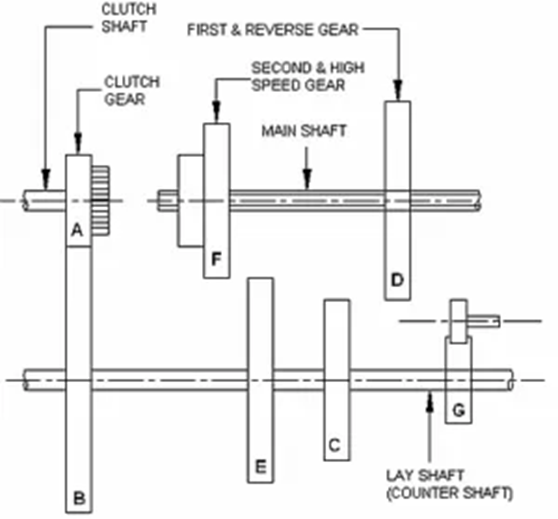

Components of a Sliding Mesh Gearbox

1. Main axis-

It is the shaft used as the output shaft in a sliding link on which gear sets with internally splined grooves are neatly arranged. The outer surface of this shaft is splined so the gears can easily slide on this shaft to mesh with the appropriate gear.

2. Clutch shaft

It is the shaft that is used to bring the output from the engine to the gearbox with the help of the clutch and disengagement which is mounted on the end of the engine, the gear or a pair of gears are mounted on this shaft which is used for transmitting the rotary movement to the placement axis.

3. Lay Shaft

It is the shaft with gears mounted on its outer surface and is in continuous rotation with the clutch shaft as a gear on this shaft is always in contact with a gear on the clutch shaft, it is used as an intermediate shaft (between the main shaft and shaft gears) which engages the main shaft gears to impart proper output to the final drive.

4. Gears –

Two types of gear were typically used in the sliding link gearbox.

Spur Gear – This is the type of gear with spur gears on its surface, spur gears demonstrating maximum gearing area.

Helical Gear – This is the type of gear where the teeth are cut at an angle, unlike spur gears, this type of gear is smooth and less noisy.

Sliding Link Gearbox Operation

Gear shifting is achieved by meshing the main shaft gears with the countershaft gears, sliding the main shaft gears to the right or left to get proper gears, making you understand the operation of the 3-speed 1-reverse transmission used in the first automotive vehicles.

Bottom gear

The first gear provides the maximum low-speed torque that occurs when the smaller gear on the countershaft meshes with the larger gear on the main shaft to provide high torque.

second gear

The second gear provides less torque and higher speed than the first and is achieved when the main shaft medium-sized gear meshes with the smaller second gear on the countershaft and high speed and the second high torque are transmitted to the final drive.

Third gear

The third gear provides maximum speed and minimum torque for the final drive and is also known as high-speed gear or top gear in a slip link gearbox, this gear is achieved when the smaller main shaft gear meshes with the shaft gear main. Larger countershaft gear. Or we can say that the transmission has reached a maximum clutch shaft speed.

Reverse gear

When reverse is selected, the output shaft rotation is reversed, which is made possible by the use of an intermediate gear between the main shaft and countershaft, which changes the output shaft rotation and the vehicle begins to move in the direction of reverse.

Applications of Sliding Mesh Gearbox

- It is the oldest type of gearbox used in car models from the early 1900s.

- Used Alfa 12HP gearbox with sliding links with a 4-speed manual gearbox.

- The Fiat 6HP used a 3-speed manual gearbox.

- Mercedes 35HP used a 4-speed manual gearbox

- The Renault Voiturette used a 3-speed manual gearbox.

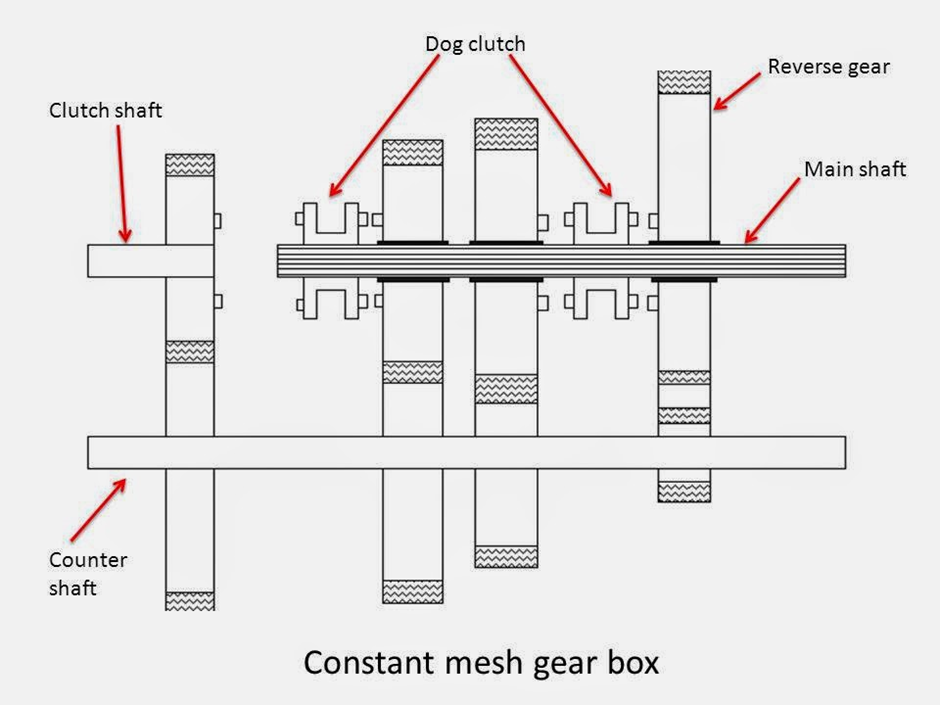

Also, read about Constant Mesh Gearbox

FAQ

What is a sliding mesh gearbox?

A sliding mesh gearbox is a type of manual transmission used in automobiles and other machinery. It consists of a set of gears that slide on splines to engage with each other, allowing the driver to select different gear ratios.

How does a sliding mesh gearbox work?

In a sliding mesh gearbox, the gears are mounted on shafts and slide laterally to engage with one another. When the driver selects a particular gear, the corresponding gear on the output shaft is moved laterally until its teeth mesh with the teeth of the input gear, transmitting power to the output shaft.

What are the advantages of a sliding mesh gearbox?

One advantage of a sliding mesh gearbox is its simplicity and robustness. It is relatively easy to manufacture and maintain, and it can handle high torque loads. It also provides direct and efficient power transmission.

What are the disadvantages of a sliding mesh gearbox?

One major disadvantage of a sliding mesh gearbox is its lack of synchronization. When shifting gears, the driver needs to match the engine speed with the speed of the gears, which requires skill and can result in rough shifts. Additionally, gear engagement can cause noise and wear.

Can a sliding mesh gearbox be used in modern vehicles?

Sliding mesh gearboxes are mostly used in older vehicles and certain specialized applications. In modern automobiles, synchronized manual transmissions or automatic transmissions are more common due to their ease of use and smoother shifting.

How many gears does a sliding mesh gearbox typically have?

A sliding mesh gearbox can have multiple gears, commonly ranging from three to six forward gears, along with a reverse gear. The specific number of gears depends on the design and intended use of the transmission.

Are sliding mesh gearboxes used in any other applications besides automobiles?

Yes, sliding mesh gearboxes can be found in various industrial and agricultural applications where manual gear shifting is required. They are used in heavy-duty machinery, tractors, construction equipment, and other similar applications.

Can a sliding mesh gearbox be retrofitted with synchronized gears?

In some cases, it is possible to retrofit a sliding mesh gearbox with synchronized gears. However, it can be a complex and costly process, requiring modifications to the transmission housing, shafts, and gears, as well as the addition of synchronization mechanisms.

Are there any alternatives to sliding mesh gearboxes?

Yes, there are several alternatives to sliding mesh gearboxes. These include synchronized manual transmissions, which use synchronizer rings to match the speeds of the gears during shifting, and automatic transmissions, which can shift gears automatically without driver input.

What is the future of sliding mesh gearboxes?

As automotive technology continues to evolve, the use of sliding mesh gearboxes is likely to decline further in favor of more advanced transmission systems. However, they may still find niche applications where their simplicity and robustness are advantageous.

Comments on “Sliding Mesh Gear Box – Construction and Working”