Table of Contents

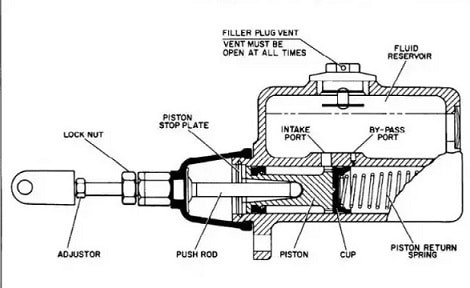

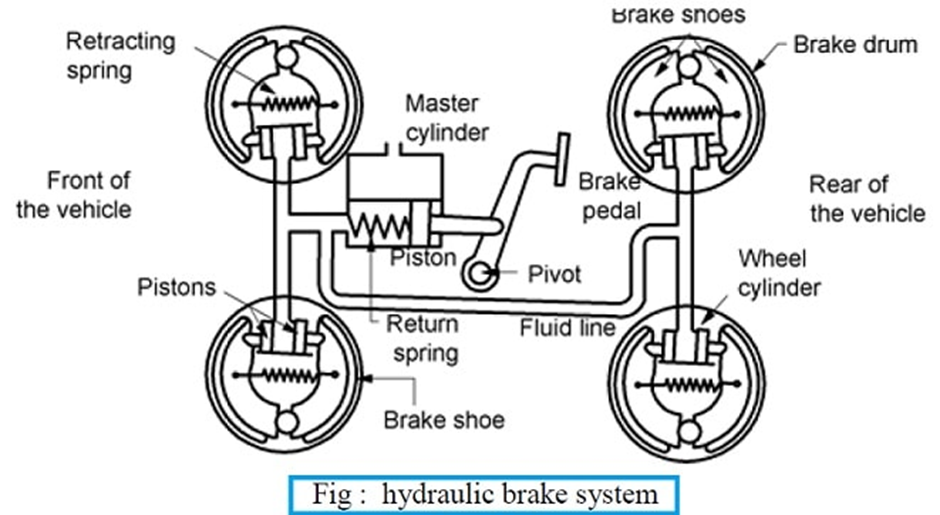

When the brake pedal is depressed, fluid in the brake master cylinder, under pressure, flows out of it and into the fluid lines leading to the wheel cylinders. It is divided into two parts, namely, the fluid reservoir and the compression chamber.

Working of Brake Master Cylinder:

When the pedal is depressed, the piston at the end of the pedal rod moves to the left, against the force of the spring, until it covers the bypass port. Further movement of the piston causes an increase in pressure in the compression chamber.

As pressure increases, the internal rubber cup of the fluid check valve flexes, forcing fluid into lines under pressure. Fluid enters the wheel cylinder and moves the piston inward, thus activating the brakes. When the pedal is released, the spring causes the piston to move to the far right position.

The force of the spring also keeps the fluid check valve pressed in its seat for some time. The fluid returns from the lines to the compression chamber and some delay occurs due to inertia.

This creates a vacuum in the compression chamber which must be destroyed immediately. When the vacuum is created, the air tries to occupy the space and negatively affects the operation of the brakes as the air is compressible.

As soon as a vacuum is created, atmospheric pressure in the fluid reservoir pushes fluid through the suction port and piston holes into the compression chamber. This destroys the void. The liquid returns to the tank by lifting the liquid check valve from its seat.

Fluid in the compression chamber becomes excessive and this excess fluid returns to the reservoir through the bypass port. Excess fluid, if allowed to remain in the compression chamber, causes the fluid to move to the lines.

Fluid is trapped in the lines and even a slight application of the brakes causes heat to be generated. This would cause fluid to expand in the lines and eventually block the brakes. The master cylinder is equipped with a rubber cover at the end of the pedal rod. This does not allow dust to enter the chamber through the opening of the pedal shaft. There is an opening at the top.

The opening is used to maintain the fluid level according to the plant’s requirements. The opening is equipped with a screw cap which makes it airtight.

TANDEM Master Cylinder

It has primary and secondary cylinders in a row. These are equipped with individual pistons and have their own return springs. The return spring holds the primary piston cup slightly behind the bypass port to keep the cylinder full of fluid. The return spring also helps return the brake pedal to its original position when the driver takes his foot off.

There are two separate lines, one connects the front wheels and the other connects the rear wheels. In a normal situation, when the pedal stem is depressed, both pistons move into the right brake fluid which is supplied to the lines, and the brakes are activated on all four wheels. In the event of a line failure, say a front line, the secondary piston moves until it reaches the cylinder wall.

Subsequently, pressure begins to build up in the space between the two pistons, and fluid is supplied to the rear wheels. The rear wheel brakes are activated. In another situation, where there is a failure in the rear fluid supply, the primary piston moves until it collides with the secondary piston.

Thereafter, the two pistons move together supplying fluid to the front wheels, thus activating the brakes on the front wheels.

FAQ

What is a brake master cylinder, and what is its purpose?

A brake master cylinder is a critical component of a vehicle’s braking system. Its purpose is to convert the force exerted on the brake pedal into hydraulic pressure, which then activates the brakes and enables the vehicle to slow down or stop.

How does a brake master cylinder work?

When the brake pedal is depressed, it pushes a piston inside the master cylinder, forcing brake fluid through the brake lines. This hydraulic pressure is transmitted to the brake calipers or wheel cylinders, which then apply pressure to the brake pads or shoes, creating friction against the rotors or drums to slow down the vehicle.

What are the common signs of a failing brake master cylinder?

Signs of a failing brake master cylinder include a spongy or sinking brake pedal, leaks around the master cylinder, low brake fluid levels, illuminated brake warning light, reduced braking efficiency, and a loss of braking power.

Can a faulty brake master cylinder affect only one wheel?

Yes, a faulty brake master cylinder can affect one or more wheels depending on the specific problem. If there is a blockage or restriction in the brake line to a particular wheel, that wheel may be affected more severely than others.

What causes a brake master cylinder to fail?

Common causes of brake master cylinder failure include internal seal deterioration, corrosion, excessive wear, contamination of brake fluid, overheating, and physical damage.

Can a brake master cylinder be repaired, or does it need to be replaced?

In most cases, a brake master cylinder cannot be effectively repaired and should be replaced. Internal components and seals may wear out or become damaged over time, making replacement the best course of action.

How often should the brake master cylinder be inspected or replaced?

There is no specific interval for inspecting or replacing the brake master cylinder since it can vary depending on factors such as driving conditions, maintenance history, and the manufacturer’s recommendations. However, it is generally a good idea to have the brake system inspected during regular maintenance intervals or if any signs of trouble arise.

Are there different types of brake master cylinders?

Yes, there are two main types of brake master cylinders: single-circuit and dual-circuit. Single-circuit master cylinders are commonly found in older vehicles, while dual-circuit master cylinders are used in most modern cars. Dual-circuit master cylinders provide an added level of safety by dividing the braking system into two separate circuits to ensure partial braking ability even if one circuit fails.

Can I upgrade my vehicle’s brake master cylinder for better performance?

In some cases, upgrading the brake master cylinder can improve braking performance. However, it is important to consider other factors such as the compatibility with the existing brake system, the vehicle’s weight and intended use, and any legal or safety implications. Consult with a qualified mechanic or brake specialist to determine the appropriate upgrade options for your vehicle.

Is it possible to drive with a faulty brake master cylinder?

Driving with a faulty brake master cylinder is highly dangerous and strongly discouraged. A malfunctioning master cylinder can compromise the braking system, leading to reduced braking power, unpredictable brake pedal behavior, and potential brake failure. If you suspect an issue with your brake master cylinder, it is crucial to have it inspected and repaired as soon as possible to ensure your safety on the road.

Comment on “Brake Master Cylinder – Detailed Working Principle”