Table of Contents

Precise relative movement of the tool relative to the workpiece is necessary to carry out the desired machining process. Motion control systems in Numerical Control (NC) machining systems can be categorized into three basic types: point-to-point, straight cut, and contour.

1. NC point to point

This type of motion control system is also known as a positioning system. The main purpose of the point-to-point (PTP) NC motion control system is to move the tool to the desired location. Tool movement speed is not an important factor in the PTP motion control system. The machining operation starts in place as soon as the tool reaches the desired position.

One of the examples of the PTP system is the NC drills. In the case of a drill, the spindle is positioned at the target location first, which is done using the PTP motion control method. A drilling operation is then performed by the spindle. PTP control is not needed when the tool moves between two holes.

PTP systems are the simplest types of motion control systems and therefore are also the least expensive of the three types of motion control methods.

2. NC Straight Cut

These types of systems move the cutting tool parallel to one of the main axes. The cutting tool is moved at a controlled rate that is suitable for the machining process. The straight cutting motion control method is, therefore, more suitable for manufacturing the rectangular part by milling operations.

However, it is not possible to combine motions on more than one major axis, which means that straight cutting motion control methods are not suitable for making angled cuts. NC machines with straight cutting motion control methods are also capable of producing PTP motions.

3. NC contour

The contour NC motion control method is the most complex and expensive among the three types of motion control systems. The method has the ability to perform PTP and NC straight cutting operations. The system can control cutting tool movement for more than one axis simultaneously.

The required geometry can be produced by continuously controlling the cutter path. Therefore, contour NC is also known as continuous path NC systems. Any type of shape can be produced under NC contour systems.

Applications of NC Systems

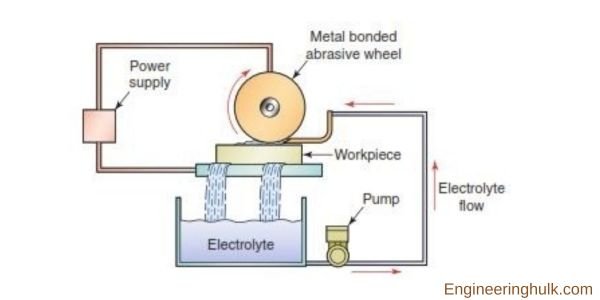

NC systems are widely used in industries for a wide range of machining operations. The most common of all applications is for cutting metal in the machining process.

The ranges of material removal processes that can be performed using NC systems include drilling, milling, sawing, boring, grinding and turning. NC systems are, however, only suitable for the production of the following types of jobs:

• Parts that are produced frequently and in small batches.

• Part geometry is complex.

• Multiple machining operations are required in one job.

• Large volume of material must be removed from the workpiece.

• Parts must be produced to close tolerances.

• Parts require inspection.

Manufacturing industries produce parts in batches of less than or equal to 50. NC machining systems are suitable for parts with small batch sizes. These NC machining systems have the ability to use the instruction program created once by the programmer to use repeatedly for the production of products of a similar nature.

Parts with complex geometries require a long and complicated program of instructions. NC machining systems have the potential to handle these parts and their programs. Any changes to the engineering drawing of a part can be easily implemented in the final product by changing the instruction program accordingly.

Tape control provides the flexibility to adapt to changes in engineering design. NC machining systems are capable of producing products with close tolerances and are therefore best suited for producing high-quality products with high accuracy and repeatability.

In addition to metallurgy, NC systems find a wide range of applicability in other machining operations such as welding, flame-cutting, pipe bending, plasma cutting, fabric cutting and automated riveting.

Advantages of NC Systems:

- NC machining systems have the following advantages in the field of production:

- Reduced downtime: NC machining system does not affect actual machining processes; however, it increases machine utilization. Machine utilization is increased with fewer steps, less machine setup time, reduced work handling time under machining, automatic tool change and so on.

- Reduced fixture: fixtures required by NC machining systems are relatively less expensive and also simpler to manufacture. Positioning is done by NC tape instead of using any jigs or fixtures.

- Reduced lead time: The lead time to deliver the final product to the customer is much shorter as the time involved in setup is shorter and fewer steps are involved in the NC manufacturing environment.

- Greater flexibility: NC machining systems can easily adapt to engineering design changes, production schedule changes, and so on.

- Greater flexibility: Parts with complex geometries which involve greater chances of human error can be optimally handled by NC manufacturing systems. The parts produced are of greater precision and therefore require less inspection time.

- Optimal inventory: the amount of inventory to be stored by a company decreases due to the reduced number of steps for manufacturing and the shorter lead time for delivery of the final product to the customer.

- Reduced Physical Space: The NC machining centre has the capability and potential to perform a number of tasks that must be performed by individual machines, the physical space utilization is improved.

Disadvantages of NC machine

- There are also certain disadvantages associated with NC fabrication systems. These are listed below:

- Higher Maintenance Cost: Maintenance of NC manufacturing systems is relatively difficult compared to conventional machining systems. This is due to the presence of complicated hardware and software systems. The maintenance cost is, therefore, higher when compared to conventional machine tools.

- Higher investment cost: NC manufacturing systems involve highly complex and sophisticated technology and are therefore capital intensive. The return on investment of the equipment can only be reasonable if the utilization of the manufacturing system is greater and, for this, the workshops are obliged to operate the machines in two or three shifts a day.

- Highly Skilled Workforce: The skills required to operate NC manufacturing systems are greater than those required to operate conventional machine tools. Skills are needed to program the machine and maintain the software and software associated with manufacturing systems.

- Thus, it is one of the disadvantages of NC manufacturing systems to employ a highly-skilled workforce for the operation of NC systems.

Comment on “Numerical Control (NC) Motion Control Systems”