Table of Contents

Types of Axles in Automobile Systems

- Rear Axles

- Front Axle

- Stub Axle

Rear Axle in Automobile

Between the differential and the drive wheels is the rear axle to transmit the power from the differential to the drive wheels. It is clear from the construction of the differential that the rear axle is not a single piece but is in two halves connected by the differential, one part known as the driveshaft.

The inner end of the drive shaft is connected to the differential sun gear. and the outer end of the drive wheel. In rear-wheel-drive vehicles, the rear wheels are the driving wheels. Whereas, in front-wheel drive vehicles, the front wheels are the driving wheels. Almost all rear axles of modern passenger cars are live axles, that is, they rotate with the wheels.

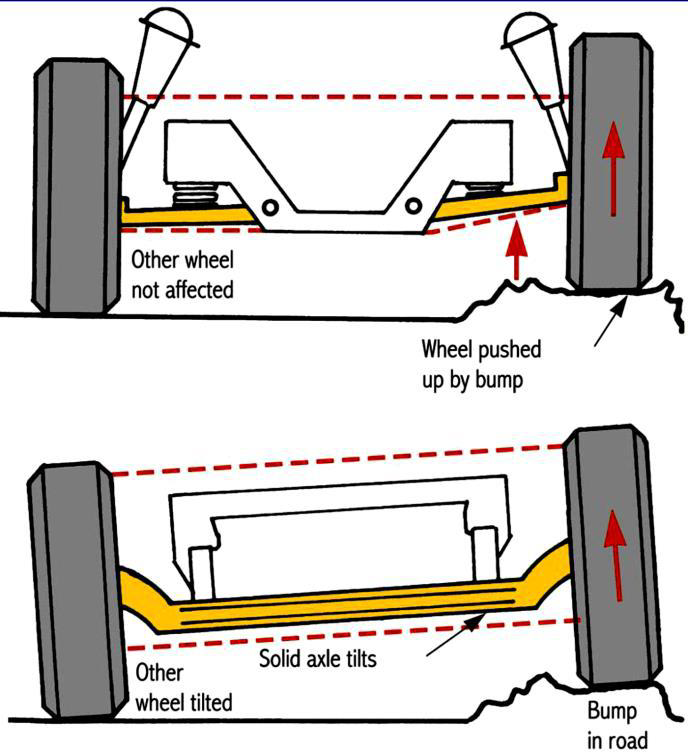

Dead axles simply remain stationary, they do not move with the wheels. A housing completely encloses the rear axles and differential, protecting them from water, dust, and injury, as well as mounting their internal bearings and providing a reservoir of lubricant.

Types of Rear Axles in Automobile Systems

Depending upon the methods of supporting the rear axles and mounting the rear wheels, the three types of rear axles are as follows:

- Semi-floating axle

- Full-floating axle

- Three-quarter floating axle

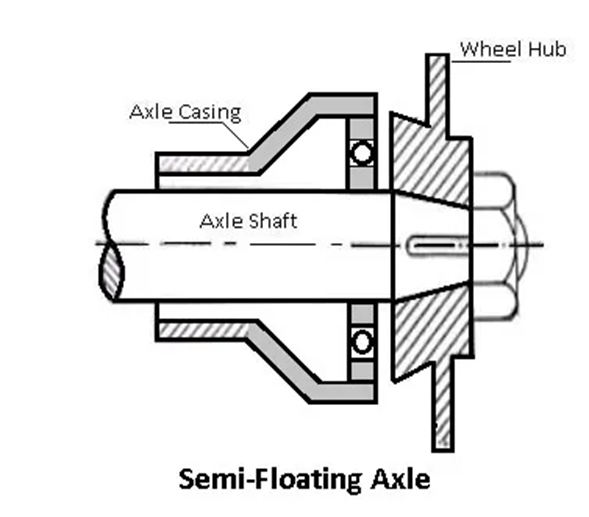

Semi-Floating Axle

A semi-floating axle has a bearing located on the axle and inside the axle housing. It must support all the loads listed above. Therefore, it must be larger in size, for the same torque delivered than any other type. The inner end of the axle is supported by the differential side gear.

He is thus relieved of the task of supporting the weight of the car via the axle housing. The outer end must support the weight of the car and absorb the final thrust. The inner end of the axle is splined to the differential side gear.

The outer end is flanged so that the wheel can be bolted directly to it. In some models, the wheel hub is keyed onto the outer end of the axle. The vehicle load is transmitted to the axle through the casing and bearing, which causes the axle to flex or shear. The semi-floating axle is the simplest and cheapest of all the other types and is widely used on cars.

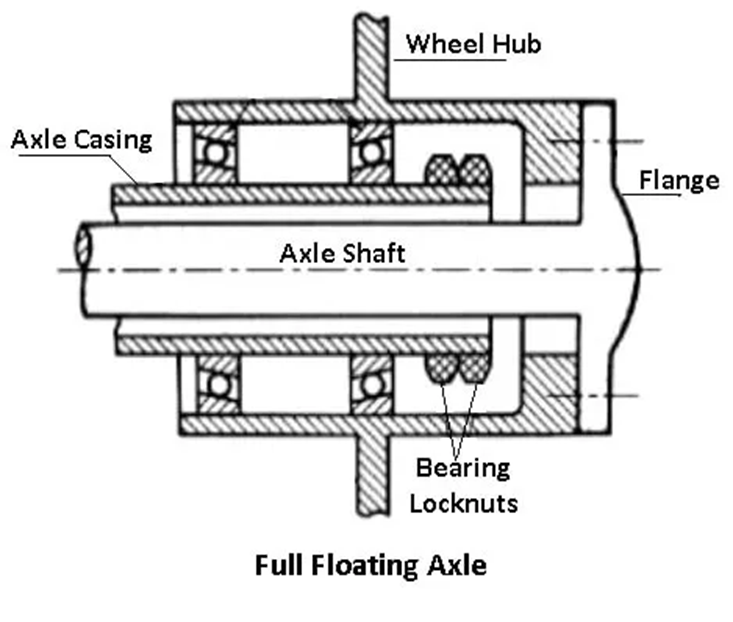

Full-Floating Axle

A fully floating axle has two deep groove balls or tapered roller bearings, which are positioned between the axle housing and the wheel hub. The outside of an axle is flanged to which the wheel hub is bolted. The axis is not supported by a bearing at both ends and its position is maintained by the way it is supported at both ends.

In this way, the axle is relieved of any stress caused by the weight of the vehicle on the final thrust. It only transmits the engine torque. For this reason, it is called full floating. The axle can be removed from the housing without distributing the wheel by removing the nuts.

An added benefit of this design is the ability of the vehicle even if it has a broken axle. This type of axle is more expensive, and heavier than the other axle. It is usually mounted on commercial vehicles.

Three-Quarter Floating Axle

This type of axle has a bearing positioned between the hub and the axle housing. Thus, the weight of the vehicle is transferred to the axle housing and only lateral thrust and drive torque are absorbed by the axle.

The axle is rigidly keyed to the hub, thus demonstrating the drive connection and maintaining wheel alignment. The inner end of this axle has the same construction as that of the semi-floating axle. Although the three-quarter floating axle is more reliable, it is not as simple as the semi-floating axle.

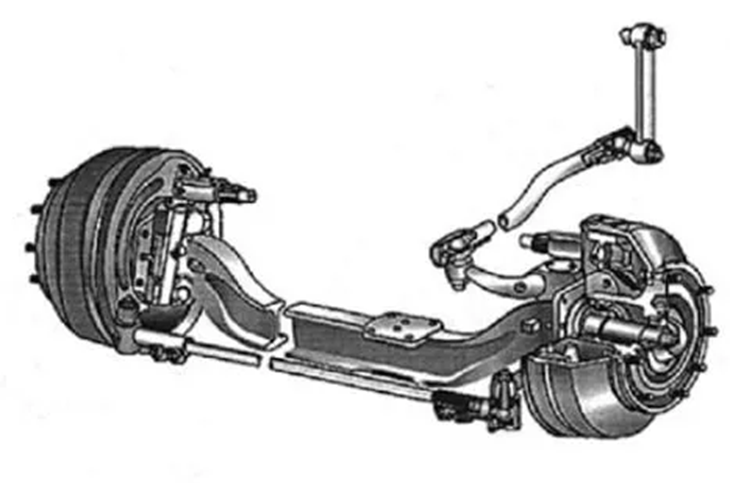

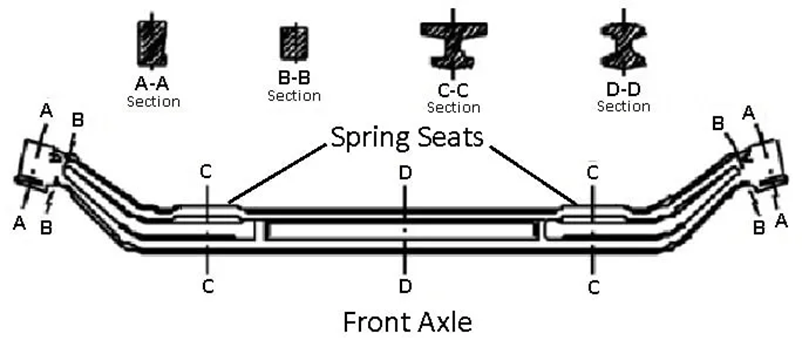

Front Axle

The front axle is used to support the weight of the front of the vehicle as well as to facilitate steering and absorb shocks due to changes in the road surface. It must be fair and robust in construction.

The front axle is usually hot-forged steel with 0.4% carbon steel or 1-3% nickel steel. It consists of an I-section in the central part, while the ends are circular or elliptical. With this construction, it withstands bending loads due to vehicle loads. Also, the middle portion of the pair is scanned downward. The different components of the front axle are the beam, the spindle, the pivot pin and the track rod.

Types of Front Axles in Automobile

Usually, there are two main types of the front axle:

- Live front axle

- Dead front axle

Front axles are usually dead axles because they don’t rotate, in contrast, to live axles which are used in the rear axle to transmit power to the rear wheels. A live front axle, with respect to the dead axle, has the additional function of transmitting the driving force drawn by a reduction gear to the front wheels having a different rotation mechanism.

Live front axles although they resemble shifter axles have some differences at the end of the axle shafts where the wheels are mounted. A dead front axle has enough stiffness and strength to carry the weight of the vehicle from the springs to the front wheels.

The ends of the axle beam are suitably formed to assemble the spindle. To accommodate a pivot pin that connects the sub-axis portion of the assembly, the ends of the beam are usually shaped like a yoke or flat surface with a hole.

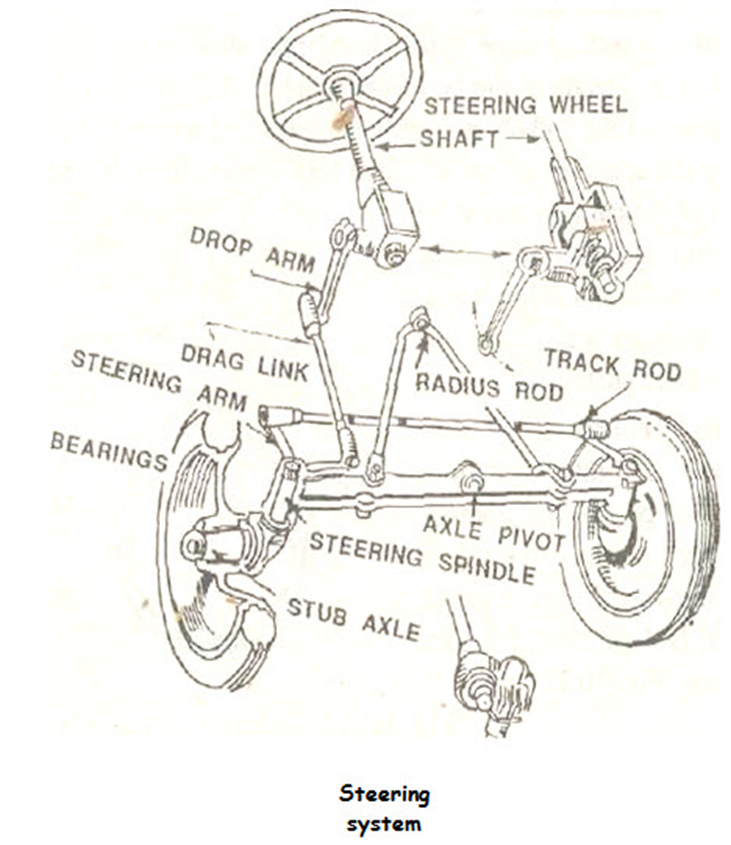

The illustration shows the components of the front axle with the steering linkage. The wheels are fixed on the spindles which are usually hinged. From the stub axle, the inclined steering arms are connected to the ends of the track rod, and a third steering arm is attached to the tie rod.

Some vehicles have the drag link positioned transversely rather than forward and in place to allow for a more compact vehicle design. It is often used in independent wheel suspension systems. The drag link connects the steering link to the steering gear release arm.

Stub Axle

The front wheels are mounted on the spindles, which are connected to the front axle via pivot pins. The spindles are forged in 3% nickel steel and alloy steels containing chromium and molybdenum.

The spindle turns on the pink pin which is a light drive that fits into the eye of the axis beam positioned and locked by a conical cotter pin. The phosphor bronze bushings are mounted in the fork ends of the axle to provide a seating surface for the pin.

The vertical load is supported by a steel washer or thrust bearing located on the upper yoke of the stub axle or between the lower yoke and the bottom of the axle beam.

Types of Stub Axles in Automobile

Following are the four types of stub axle:

- Elliot.

- Reverse Elliot.

- Lamoine.

- Reversed Lamoine.

The Elliot stub axle is attached to the front axle by placing it in the yoke end with a kingpin and cotter to join the two together.

FAQ about Types of Axles

What are the different types of axles used in automobiles?

There are primarily three types of axles used in automobiles: front axles, rear axles, and stub axles.

What is a front axle?

The front axle is responsible for transmitting power from the engine to the front wheels. In most front-wheel-drive vehicles, it combines the functions of a drive axle and steering axle.

What is a rear axle?

The rear axle delivers power from the transmission to the rear wheels and is commonly found in rear-wheel-drive and four-wheel-drive vehicles.

What is a stub axle?

A stub axle, also known as a spindle, is a short axle that supports the front wheels and allows them to rotate. It is typically used in independent front suspension systems.

What is a live axle?

A live axle is an axle that transmits power to the wheels while also supporting the weight of the vehicle. It is commonly found in solid rear axle setups.

What is an independent suspension axle?

An independent suspension axle allows each wheel to move independently, providing a smoother ride and improved handling. It is commonly used in modern vehicles to enhance comfort and stability.

What is a dead axle?

A dead axle is an axle that does not transmit power to the wheels. It is primarily used to support the weight of the vehicle and is commonly found in trailers and heavy-duty trucks.

What is a semi-floating axle?

A semi-floating axle is a type of axle where the weight of the vehicle is supported by the axle shaft, and the axle shaft is responsible for transmitting power to the wheels. It is commonly used in light to medium-duty vehicles.

What is a full-floating axle?

A full-floating axle is a type of axle where the weight of the vehicle is supported by the axle housing, and the axle shaft is solely responsible for transmitting power to the wheels. It is commonly used in heavy-duty trucks and off-road vehicles.

What are the advantages of different types of axles?

1. Front axles allow for better weight distribution and improved traction in front-wheel-drive vehicles.

2. Rear axles provide better balance and stability in rear-wheel-drive and four-wheel-drive vehicles.

3. Independent suspension axles offer improved ride quality and handling.

4. Live axles are known for their durability and strength.

5. Dead axles are simple in design and cost-effective.

6. Semi-floating axles strike a balance between cost and load-carrying capacity.

7. Full-floating axles provide maximum load-carrying capacity and ease of maintenance.

welcome, exalted blog on lardy loss. such a person helped.