Table of Contents

Mechanical brakes

Mechanical brakes consist of mechanical elements for the deceleration or stop of axes in equipment drives. They use levers or links to transmit force from one point to another. Braking slows or stops the movement of the coupled axes. There are several types of mechanical brakes. Band brakes, the simplest brake configuration, have a metal band lined with heat and wear-resistant friction material.

Drum brakes, commonly used on the rear wheels of cars, work when shoes press against a rotating surface called a drum. Disc brakes are built with brake pads, a caliper, and a rotor. During operation, the brake pads are pressed against the rotor. Cone brakes are made with a cup and a cone, which are lined with heat and wear-resistant material. During actuation, the cone is pressed against the surface of the coupling cup.

DISC BRAKE

The disk brake may be a device for slowing or stopping the rotation of a wheel while it’s in motion. A brake disc is usually made from forged iron, but in some cases, it is often made from composite materials like carbon-carbon or ceramic matrix-reinforced composites. This is connected to the wheel axle.

To stop the wheel, the friction material within the sort of restraint (mounted during a device called a brake caliper) is forced hydraulically, pneumatically, or electromagnetically against both sides of the disc. Friction causes the disc and the connected wheel to slow down or stop. The brakes convert motion into heat, and if they overheat, they subside effectively, a phenomenon referred to as brake fade.

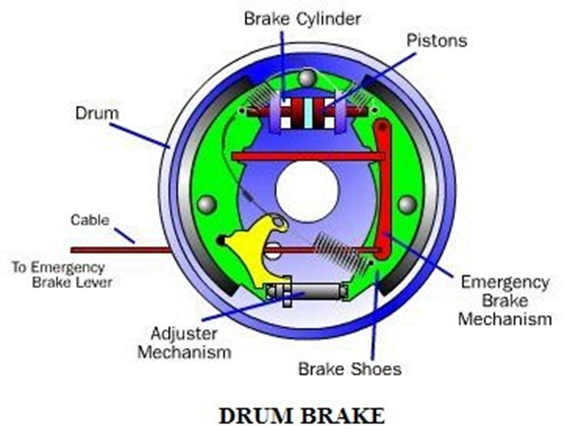

DRUM BRAKES

A drum brake is a brake in which friction is caused by a series of pads or pads pressing against a rotating drum-shaped part called a brake drum. This term generally means a brake in which the shoes press on the inner surface of the drum. When the shoes press on the outside of the drum, it is generally called a buckle brake.

When the drum is squeezed between two shoes, similar to a conventional disc brake, it is sometimes called a “caliper drum brake”, although such brakes are relatively rare. A related type of brake uses a flexible strap or “band” that wraps around the outside of a drum, called a band brake.

Band Brakes

Band brakes consist of a flexible band made of steel or other material that wraps around a drum. The band is connected to a lever or pedal, which causes it to tighten around the drum when pressed. The friction between the band and the drum slows down or stops the wheel’s rotation. Band brakes are commonly found on bicycles, motorcycles, and some industrial machinery.

Components of Mechanical Brakes

Some of the components of mechanical brakes are as follows

- Brake Shoes or Pads: These are made of friction material that presses against the drum or rotor to create friction and slow down the wheel’s rotation.

- Brake Drum or Rotor: This is a rotating component that the brake shoe or pad presses against to create friction and slow down the wheel’s rotation.

- Caliper or Brake Lever: This is the component that applies pressure to the brake shoe or pad to create friction and slow down the wheel’s rotation.

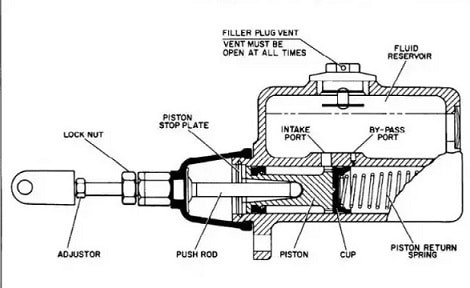

- Brake Fluid: This is used in hydraulic brakes to transfer the pressure from the brake pedal to the caliper or brake lever.

Working principle of Mechanical brakes

Mechanical brakes work by converting kinetic energy (motion) into thermal energy (heat) through friction. When the brake pedal or lever is pressed, the brake shoe or pad presses against the drum or rotor, creating friction. This friction converts the kinetic energy of the moving object into thermal energy, which is dissipated into the environment. As a result, the object slows down or comes to a stop.

Advantages of Mechanical brakes

- Reliability: Mechanical brakes are simple and reliable, making them ideal for use in harsh environments or where other types of brakes may fail.

- Cost-effective: Mechanical brakes are less expensive than other types of brakes, making them a cost-effective solution for many applications.

- Easy to maintain: Mechanical brakes are easy to maintain, and most of the components can be replaced individually, which reduces downtime and repair costs.

Disadvantages of Mechanical brakes

- Low stopping power: Mechanical brakes have limited stopping power compared to hydraulic or electromagnetic brakes, making them unsuitable for high-performance applications.

- Heat buildup: Mechanical brakes generate a significant amount of heat, which can cause damage to the components or affect their performance if they are not properly cooled.

- Wear and tear: Mechanical brakes experience wear and tear, which reduces their performance over time and requires frequent replacement of brake

Comments on “Mechanical Brakes – Types, working, advantages & disadvantages”