Table of Contents

In fluid dynamics, orifice meters play a crucial role in accurately measuring the flow rate of liquids and gases. These devices are widely used in various industries, including oil and gas, chemical, and water management.

Definition of Orifice Meters

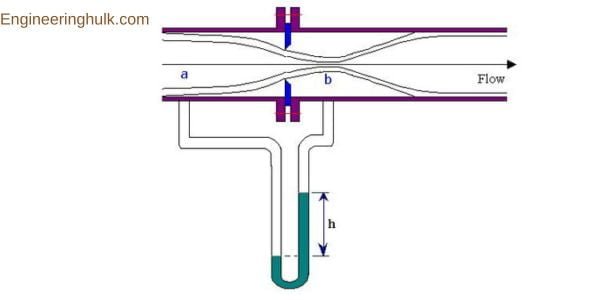

An orifice meter is a type of flow measurement device that utilizes a precisely sized orifice plate to create a pressure drop across a flowing stream. By measuring the pressure difference, the flow rate of a fluid passing through the orifice can be determined. Orifice meters are particularly useful for measuring the flow of liquids, gases, and steam in pipelines.

Construction of Orifice Meters

Orifice meters consist of three primary components: the orifice plate, the holder, and the pressure tappings.

1. Orifice Plate:

The orifice plate is a thin, flat circular plate with a precisely drilled hole, known as the orifice bore, at its center. The plate is typically made of stainless steel or other corrosion-resistant materials. The diameter of the orifice bore is carefully calculated based on the desired flow range and the properties of the fluid being measured.

2. Holder:

The orifice plate is held in place within the pipe by a holder, which is designed to provide a stable and secure fit. The holder ensures that the orifice plate is centered and aligned correctly within the pipe to obtain accurate measurements. It also helps to minimize the flow disturbances caused by the presence of the orifice plate.

3. Pressure Tappings:

Pressure tappings are small holes drilled in the pipe upstream and downstream of the orifice plate. These tappings allow pressure sensors or gauges to be connected to measure the differential pressure across the orifice. The pressure difference is a critical parameter used to calculate the flow rate through the orifice.

Working Principles of Orifice Meters

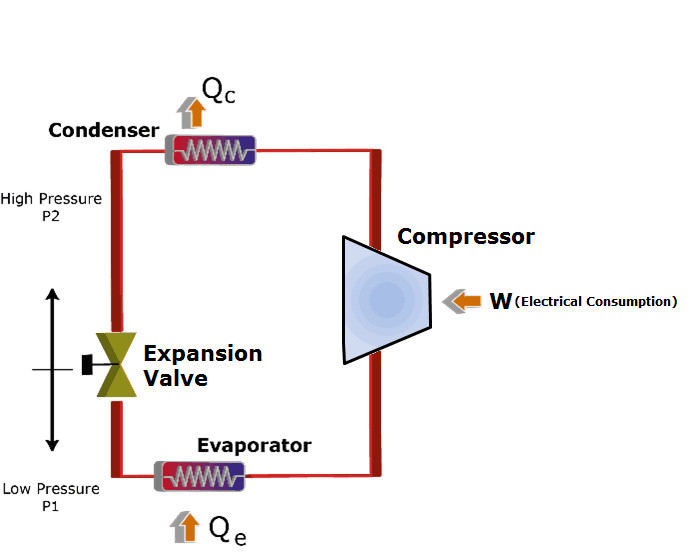

When fluid flows through a pipeline containing an orifice meter, it passes through the orifice plate, causing a reduction in the cross-sectional area. This reduction creates a constriction point, leading to an increase in fluid velocity and a corresponding decrease in pressure. The pressure drop is measured using pressure sensors connected to the pressure tappings.

The flow rate through the orifice is determined by calculating the square root of the pressure drop across the orifice and applying the principles of fluid mechanics. The calculation involves using established equations, such as the Bernoulli equation and the orifice equation, which considers factors such as the fluid density, orifice diameter, and coefficient of discharge.

Orifice Meter Formula and its Derivation

Orifice Meter Formula

The basic formula used to calculate the flow rate through an orifice meter is known as the orifice equation or the discharge equation. It can be expressed as follows:

Q = Cd * A * √(2ΔP / ρ)

Where:

Q = Flow rate (volume per unit time)

Cd = Coefficient of discharge

A = Area of the orifice

ΔP = Pressure drop across the orifice

ρ = Density of the fluid

Derivation of the Orifice Meter Formula

The orifice meter formula can be derived using the principles of Bernoulli’s continuity equations. Let’s walk through the derivation step by step:

Step 1: Start with Bernoulli’s equation, which states that the total energy of a fluid remains constant along a streamline.

P₁/ρ + V₁²/2 + gz₁ = P₂/ρ + V₂²/2 + gz₂

Where:

P₁ and P₂ = Pressures at points 1 and 2

ρ = Density of the fluid

V₁ and V₂ = Velocities at points 1 and 2

g = Acceleration due to gravity

z₁ and z₂ = Elevations at points 1 and 2

Step 2: Assume that the fluid velocity before the orifice (point 1) is negligible compared to the velocity through the orifice (point 2). Therefore, V₁ can be considered zero.

P₁/ρ + gz₁ = P₂/ρ + V₂²/2 + gz₂

Step 3: Simplify the equation by canceling out the elevation terms (gz₁ and gz₂).

P₁/ρ = P₂/ρ + V₂²/2

Step 4: Introduce the pressure difference ΔP = P₁ – P₂.

ΔP/ρ = V₂²/2

Step 5: Solve for V₂.

V₂ = √(2ΔP / ρ)

Step 6: Apply the continuity equation, which states that the mass flow rate is constant in an incompressible fluid.

Q₁ = Q₂

A₁V₁ = A₂V₂

Since V₁ is negligible compared to V₂, A₁V₁ can be considered zero.

A₂V₂ = Q

Step 7: Substitute the value of V₂ from Step 5 into the continuity equation.

A₂√(2ΔP / ρ) = Q

Step 8: Solve for Q.

Q = A₂ * √(2ΔP / ρ)

Step 9: Finally, introduce the coefficient of discharge Cd, which accounts for losses due to friction and other factors.

Q = Cd * A * √(2ΔP / ρ)

Advantages and Applications of Orifice Meters

Orifice meters offer several advantages, making them a popular choice for flow measurement in various industries:

1. Cost-effective: Orifice meters are relatively inexpensive compared to other flow measurement devices, making them a cost-effective solution for many applications.

2. Simple design: The construction of orifice meters is straightforward, with fewer moving parts, which reduces the chances of mechanical failure and simplifies maintenance.

3. Wide range of applications: Orifice meters can handle a wide range of fluid types, temperatures, and pressures, making them versatile instruments suitable for diverse industries, including oil and gas, chemical processing, water management, and HVAC systems.

4. Accuracy: With proper installation and calibration, orifice meters can provide accurate flow rate measurements within an acceptable margin of error.

FAQ

How does an Orifice Meter work?

When fluid passes through the orifice plate, the flow is constricted, creating a pressure drop across the orifice. By measuring this pressure drop, the flow rate can be calculated using Bernoulli’s equation and other fluid dynamics principles.

What are the advantages of using Orifice Meters?

Orifice Meters are simple in design and relatively inexpensive.

They can handle a wide range of fluid types, including liquids, gases, and steam.

Orifice Meters have a predictable and repeatable flow measurement performance.What are the limitations of Orifice Meters?

They cause a permanent pressure drop in the system, leading to energy losses.

Accuracy can be affected by changes in fluid properties, such as temperature and viscosity.

Orifice Meters are sensitive to pipe misalignments or irregularities.Are there different types of Orifice Meters?

Yes, there are mainly three types:

Concentric Orifice: The most common type, with the orifice centered in the pipe.

Eccentric Orifice: The orifice is offset from the center, useful for dirty or viscous fluids.

Segmental Orifice: A variation of the eccentric design, often used for higher flow rates.How are Orifice Meters sized?

Sizing an Orifice Meter involves considering factors such as fluid properties, flow rate range, and desired pressure drop. The size of the orifice diameter is critical in achieving accurate flow measurement.

Can Orifice Meters handle high-pressure applications?

Yes, Orifice Meters can be designed to withstand high-pressure applications, making them suitable for a wide range of industrial processes.

How do you compensate for changes in fluid properties with Orifice Meters?

To compensate for variations in fluid properties (e.g., temperature and viscosity), it is common to use flow computer systems that apply corrections based on the known fluid characteristics.

Are Orifice Meters suitable for all flow measurement scenarios?

While Orifice Meters are versatile, they may not be ideal for low-flow applications, as the permanent pressure drop can be relatively significant compared to the flow being measured.

What is the maintenance requirement for Orifice Meters?

Orifice Meters require periodic inspection and cleaning, especially if used for measuring dirty or corrosive fluids. The orifice plate may need replacement over time due to wear or damage. Regular calibration is essential to maintain accurate measurements.

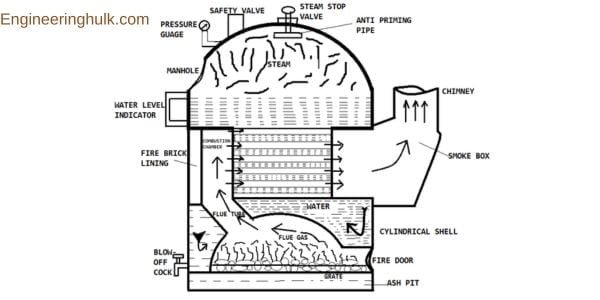

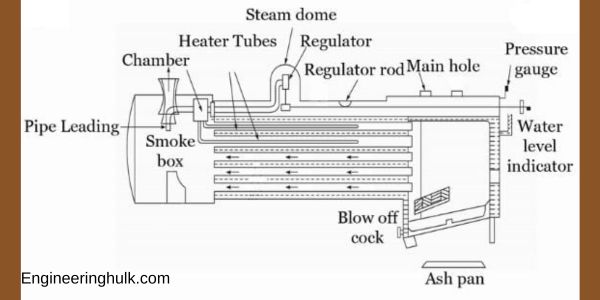

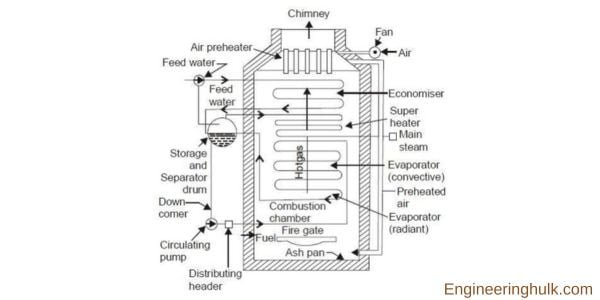

Also, read the Cochran boiler

Comment on “Orifice Meters: Definition, Construction, and Working”

Comments are closed.