Table of Contents

Introduction

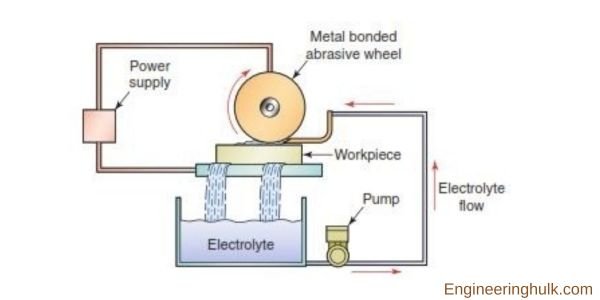

In manufacturing, the need for efficient and precise machining processes is paramount. One such process that has gained considerable attention is electrochemical grinding (ECG). By combining the principles of electrochemical machining and conventional grinding, ECG offers a unique solution to achieving high precision and surface finish in various materials.

Definition of Electrochemical Grinding (ECG)

Electrochemical grinding (ECG) is a specialized form of grinding that utilizes the principles of electrochemical machining (ECM) and abrasive grinding. It is a non-traditional machining process that combines the benefits of both techniques to achieve superior machining precision, surface finish, and material removal rates. ECG involves the use of an electrolyte and a grinding wheel, which is typically conductive and coated with abrasives.

Construction of an Electrochemical Grinding System

An electrochemical grinding system consists of several key components, each playing a crucial role in the overall process. The main elements of an ECG system include:

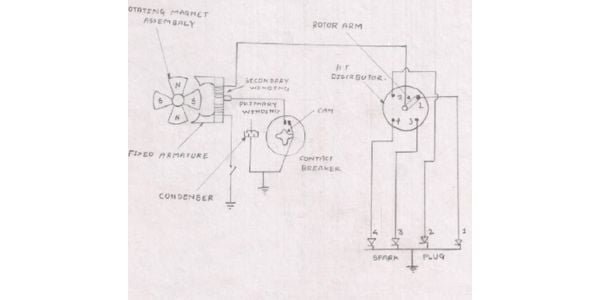

1. Power Supply:

A direct current (DC) power supply is employed to provide the necessary electrical energy for the electrochemical reactions to occur. The power supply controls the machining parameters such as voltage, current, and frequency.

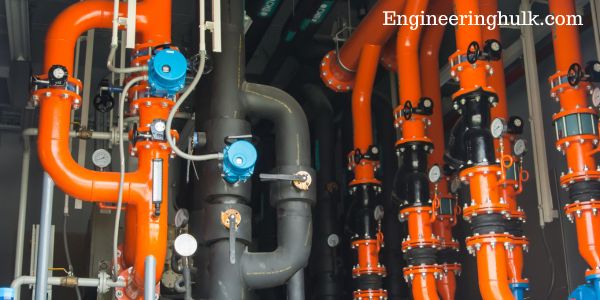

2. Electrolyte:

An electrolyte solution, often an aqueous solution, is used to facilitate the electrochemical reactions. The electrolyte acts as a conductive medium and aids in the removal of material from the workpiece.

3. Grinding Wheel:

The grinding wheel in ECG is composed of a conductive bond material embedded with abrasive particles. The conductive nature of the wheel enables the electrochemical reactions to take place, while the abrasive particles assist in material removal.

4. Workpiece:

The workpiece is the material being machined in the ECG process. It is typically made of conductive materials such as steel, stainless steel, superalloys, or titanium.

5. Tooling and Fixturing:

Proper tooling and fixturing are crucial in ensuring stable workpiece positioning and alignment during the ECG process. They help maintain accuracy, precision, and consistency in machining operations.

Working Principles of Electrochemical Grinding

The working principles of electrochemical grinding involve a combination of electrochemical and mechanical actions. The process can be summarized in the following steps:

1. Set-Up:

The workpiece is mounted securely in the ECG machine using appropriate fixturing. The grinding wheel is positioned opposite the workpiece, with a small gap maintained between them.

2. Electrolyte Flow:

The electrolyte solution is continuously supplied between the grinding wheel and the workpiece. It serves as a conductive medium and facilitates the electrochemical reactions.

3. Electrochemical Reactions:

When the power supply is activated, a potential difference is created between the grinding wheel (anode) and the workpiece (cathode). This potential difference initiates electrochemical reactions, leading to the dissolution of the workpiece material.

4. Mechanical Abrasion:

As the electrochemical reactions occur, the conductive grinding wheel, coated with abrasive particles, also exerts a mechanical force on the workpiece. This dual action of electrochemical dissolution and abrasive grinding results in efficient material removal.

5. Surface Finish and Precision:

Electrochemical grinding offers excellent control over material removal, resulting in superior surface finish and dimensional accuracy. The process minimizes heat generation, reducing the risk of thermal damage to the workpiece.

Advantages and Applications

ECG offers several advantages

over traditional grinding methods, including:

– Improved surface finish and precision

– Reduced heat generation and thermal damage

– Ability to machine complex and delicate parts

– High material removal rates

– Minimized tool wear

These advantages make ECG suitable for a wide range of applications, such as:

– Aerospace and aviation industry

– Medical device manufacturing

– Automotive industry

– Precision tool and die manufacturing

– Electronic components fabrication

Also, read the Orifice meter

Comment on “Electrochemical Grinding: Definition, Construction, Working”

Comments are closed.