Table of Contents

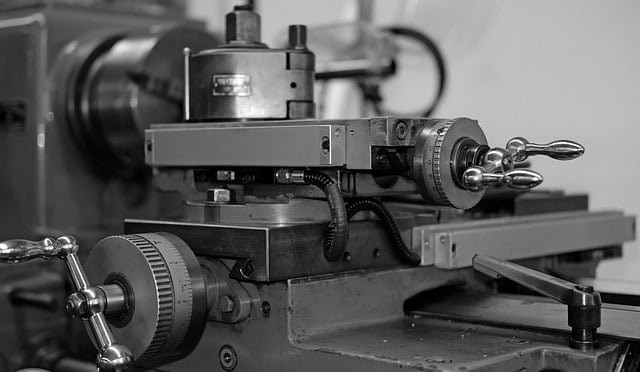

Lathe machine parts:

A lathe machine is a tool used to shape, cut, drill, or turn a workpiece by rotating it against a cutting tool. The machine is composed of several parts, including:

- Bed: The base of the lathe machine that supports all other parts. It is typically made of cast iron and provides a stable platform for the machine.

- Headstock: The part located on the left end of the bed that houses the spindle. The spindle holds and rotates the workpiece at different speeds.

- Tailstock: The part located on the right end of the bed that supports the other end of the workpiece. It can be moved along the bed to accommodate different lengths of workpieces.

- Carriage: The part located between the headstock and tailstock that moves along the bed to support the cutting tool. It consists of a saddle that moves back and forth along the bed and a cross-slide that moves perpendicular to the bed.

- Apron: The part located on top of the carriage that contains the gears and levers used to control the movement of the carriage and cutting tool.

- Chuck: The device attached to the spindle that holds and rotates the workpiece.

- Tool post: The part attached to the top of the cross-slide that holds the cutting tool. It can be adjusted to different angles and heights to accommodate different types of cuts.

- Cutting tool: A hardened steel tool mounted on the tool post that shapes and cuts the workpiece.

- Feed rod: The part used to control the movement of the cutting tool along the workpiece. It is usually located on the apron and can be operated manually or through an automatic feed system.

- Leadscrew: A long threaded rod located on the bed that moves the carriage along the bed. It is typically operated by a gear train located in the apron.

Also, read Automobile Clutch Friction Materials

Comment on “Lathe machine parts”

Comments are closed.