Table of Contents

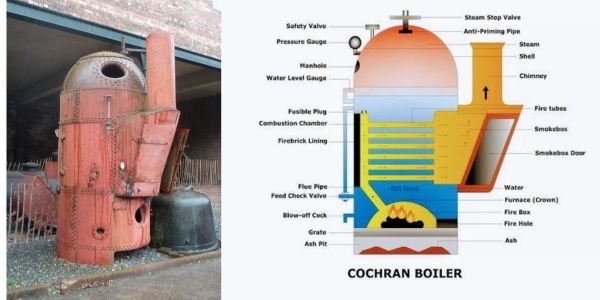

In industrial boilers, the Cochran boiler holds a significant place. It is a popular and efficient type of steam boiler widely used in various industries.

What is a Cochran Boiler?

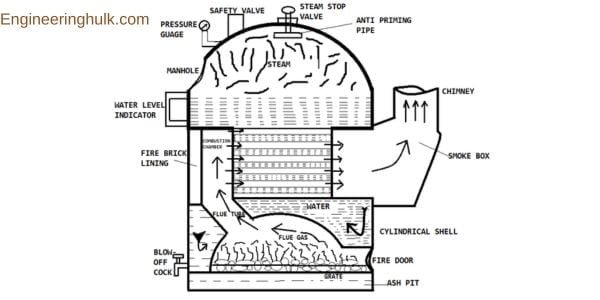

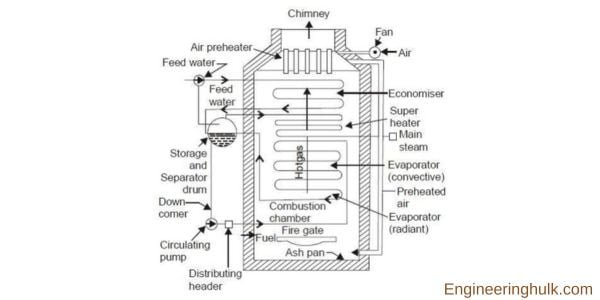

A Cochran boiler is a vertical, multi-tubular, fire-tube boiler that generates steam by transferring heat from the hot gases produced during the combustion process to the water surrounding the tubes. It was designed by engineer and inventor John Cochran in 1890. Over the years, it has become one of the most trusted and widely used boiler types in the industry.

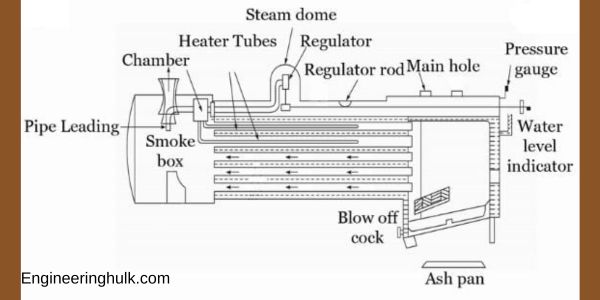

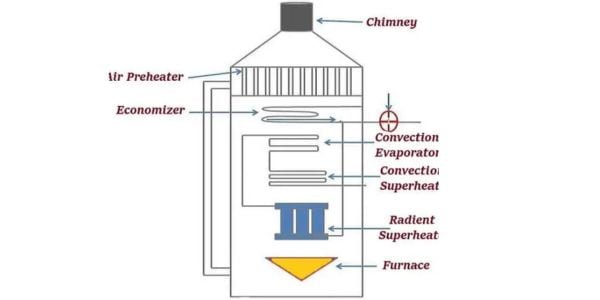

Components of a Cochran Boiler

1. Shell:

The shell is a cylindrical vessel that houses the water and steam. It is constructed with high-quality steel to withstand high pressure.

2. Furnace:

The furnace is located at the lower part of the boiler where the combustion of fuel takes place. It is surrounded by water on all sides, ensuring maximum heat transfer.

3. Grate:

The grate is situated at the bottom of the furnace and serves as a platform for the fuel to burn. It allows the air to pass through for efficient combustion.

4. Combustion Chamber:

The combustion chamber is the area where the burning of fuel occurs. It is lined with fire bricks to withstand high temperatures.

5. Tubes:

Cochran boilers have multiple small-diameter fire tubes that run vertically through the boiler. These tubes facilitate the transfer of heat from the hot gases to the water.

6. Mountings and Fittings:

Various mountings and fittings such as safety valves, water level indicators, pressure gauges, and blowdown valves are installed to ensure the safe and efficient operation of the boiler.

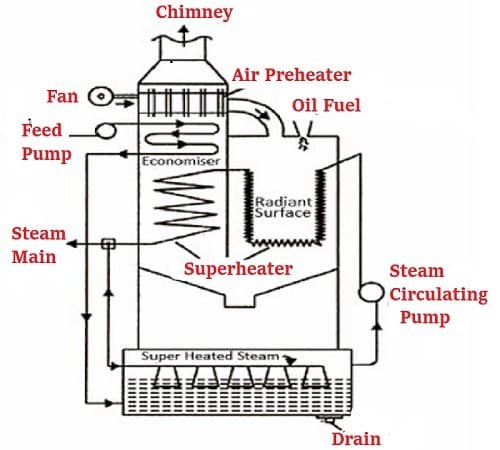

Working Principle of a Cochran Boiler

The working principle of a Cochran boiler involves the following steps:

1. Fuel Combustion:

The fuel, which can be coal, oil, or gas, is burned in the furnace. The combustion generates hot gases and releases heat energy.

2. Heat Transfer:

The hot gases rise through the flue gas path, heating the surrounding water in the shell and the tubes. Heat transfer takes place through convection and radiation.

3. Steam Generation:

As the water absorbs heat from the hot gases, it starts boiling and forms steam. The steam is collected in the upper part of the shell.

4. Steam Distribution:

The generated steam can be used for various applications. It is distributed through pipes to the desired location, where it performs mechanical work or heating tasks.

Characteristics of a Cochran Boiler

1. Compact and Space-Efficient Design

Cochran boilers are designed with a compact structure, making them an excellent choice for installations with limited space. The vertical arrangement of the boiler and its multi-tubular design enable it to occupy a smaller footprint compared to other boiler types. This characteristic makes Cochran boilers highly suitable for a wide range of industrial settings where space optimization is crucial.

2. Multi-Tubular Construction

One of the standout characteristics of Cochran boilers is their multi-tubular construction. These boilers feature a multitude of small-diameter fire tubes that run vertically through the unit. The numerous tubes significantly increase the heating surface area, facilitating efficient heat transfer from the hot gases to the surrounding water. This design maximizes the boiler’s thermal efficiency, resulting in enhanced steam generation and fuel economy.

3. Versatility in Fuel Options

Cochran boilers are highly versatile when it comes to fuel options. They can effectively burn a variety of fuels, including coal, oil, and gas. This versatility allows the boiler to adapt to different industrial requirements and fuel availability, offering flexibility and convenience to operators. Industries can choose the most suitable fuel source based on cost, availability, and environmental considerations.

4. Robust and Durable Construction

The construction of Cochran boilers emphasizes durability and longevity. These boilers are built with high-quality steel, ensuring robustness and resistance to high pressures. The shell, furnace, and combustion chamber are constructed to withstand the rigors of industrial operations, providing a reliable and long-lasting solution for steam generation needs.

5. High Thermal Efficiency

Cochran boilers are renowned for their high thermal efficiency. The multi-tubular design, combined with efficient heat transfer mechanisms, enables these boilers to extract maximum heat from the fuel and transfer it to the water. This optimized heat transfer process results in improved fuel utilization and reduced energy wastage, making Cochran boilers an environmentally friendly and cost-effective choice for steam generation.

6. Easy Operation and Maintenance

Another notable characteristic of Cochran boilers is their ease of operation and maintenance. These boilers are designed to be user-friendly, with accessible components that facilitate regular inspection, cleaning, and maintenance tasks. Operators can easily monitor water levels, pressure, and other parameters through the boiler’s integrated mountings and fittings, ensuring safe and efficient operation.

7. Safety Features

Cochran boilers are equipped with essential safety features to protect personnel and equipment. Safety valves are installed to release excess steam and prevent pressure buildup, ensuring the boiler operates within safe limits. Water level indicators provide a clear indication of water levels inside the boiler, allowing operators to maintain optimum water levels. These safety measures contribute to the secure and reliable operation of Cochran boilers.

| Feature/Component | Description |

|---|---|

| Construction | Vertical, cylindrical |

| Fire-tube | Multi-tubular |

| Mounting | Stationary |

| Fuel Used | Coal, oil, or gas |

| Number of Fire Tubes | Multiple, usually more than one |

| Working Pressure | Typically up to 15 bar, but can vary |

| Efficiency | 70-75% with coal, higher with oil/gas |

| Shell Diameter | Varies – can be up to 2.75 meters |

| Height of the Boiler | Up to 7.5 meters |

| Grate Area | Area where the coal is burned |

| Heating Surface Area | Usually around 20 to 30 m^2 |

| Water Capacity | Typically up to 9,000 liters |

| Steam Capacity | Varies – around 2,500 to 6,500 kg/hour |

| Flue Gas Path | From the furnace, gases move through the fire tubes, then discharged to the atmosphere through the chimney |

| Safety Valve | Used to release pressure and prevent explosion |

| Blow-off Cock | Removes sediment settled at the bottom of the boiler |

| Feed Check Valve | Controls the flow of water from the feed pump to the boiler |

| Steam Stop Valve | Controls the flow of steam from the boiler |

| Chimney | Releases burnt gases into the atmosphere |

| Fusible Plug | Melts and releases steam in the event of water levels getting too low to prevent boiler damage |

| Manhole | Provides access to the boiler for inspection and cleaning |

| Fire Hole | Place where fuel is added |

Applications of Cochran Boilers

Cochran boilers find applications in a wide range of industries, including:

1. Power Generation: They are used in power plants to produce steam for electricity generation.

2. Textile Industry: Cochran boilers provide steam for various textile processes, including dyeing, printing, and fabric finishing.

3. Food Processing: They are utilized

in food processing plants for cooking, drying, and sterilization purposes.

4. Pharmaceutical Industry: Cochran boilers play a vital role in the pharmaceutical industry, providing steam for sterilization and other processes.

5. Chemical Industry: They are employed in chemical plants for heating, distillation, and other chemical reactions.

Also, read Chemical Machining

Comment on “The Cochran Boiler: Components, Working, & Applications”

Comments are closed.