Table of Contents

All of the workshop engineer’s energy is directed towards some aspect of changing the shape of the metal, and we will now discuss the general issue of hot and cold working. Cold working means subjecting the metal to forces that cause it to undergo plastic deformation when it is below the lowest critical temperature (perlite condition).

Hot-working is the same when the metal is above the lowest critical temperature. The processes included are forging, bending, rolling, drawing, hammering, etc. to wrought iron and steel, and in general to non-ferrous metals that can be worked.

Cold Working

Cold work may seem strange at first why working steel at 600°C, which is a dull red heat, should be included in the cold working category. When one remembers, however, that the pearlitic structure remains unchanged until the critical lower blast above 700°C), it will be seen that the effect on pearlite of plastic work will be the same at any temperature below this.

Cold working distorts the crystalline structure of the metal and makes it harder and more brittle. Unless, however, the metal has been worked so hard that it cracks, its structure can be brought back to its original state by annealing.

Whatever the distortion in the steel structure below the critical range, when it is brought to the higher critical temperature it recrystallizes to austenite and then, if cooled normally, turns back into pearlite with little trace of the original mistreatment. The reader can imagine that when the metal was bent and straightened again, given a certain amount of permanent stretching, or given some other similar treatment, it lost its ‘nature’ and became useless.

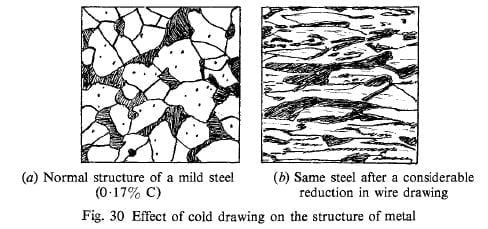

This is not the case, as long as the metal has not cracked, the treatment will only make it a little harder, stronger and more brittle, and it can be brought back to its original condition by annealing or normalizing. If, of course, the treatment made the metal so brittle that it cracked, then we can say that it has lost its ‘nature’ or any other word we like to use, as the only cure is scrap and repurposing. Melting. As we will discuss later, cold-rolled, wiredrawn, cup drawn, cold head, cold bent, etc. The distortion in the mild steel structure is caused by being drawn into wire.

Hot working

It consists of changing the shape of steel when its temperature is above the critical upper and is used in hot rolling, forging, upsetting, etc. Hot-working refines the steel structure by crushing large grain formations and closing any cavities that may be present. The moulding of hot plastic steel can be by blows, as from a hammer or drop stamp, or the metal can flow in a slower, more uniform motion, as by the pressure of a hydraulic press.

Hammering processes tend to give more complete effects than pressing, which is more in the nature of kneading. Where the thickness of the metal is large, the effects of hammering may not penetrate completely, and the surface of the metal will be better worked than the one below. If forging is carried out with the strength requirements of the finished article in mind, a much better and more reliable product can be obtained.

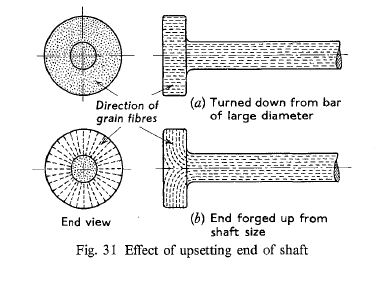

This is because steel, to some degree, exhibits directional qualities in its grain and, by proper forging, the flow of the metal can be controlled so that the grain direction increases strength. The figure is of a gear, solid with an axle. In (a) it is shown how the grain would run if the whole were turned from a solid bar, while in (b) the grain shine caused by forging the end of a bar is shown.

The metal in the gear teeth cut into the gear in (b) will be more durable than in (a). The figure shows the grain direction on a forged crankshaft, where again it can be seen that the grain’s directional qualities add toughness to the souls and where they bond to the rounded parts of the shaft.

Overheated steel

Sometimes, by accident, steel is heated to a very high temperature – almost melting. This causes the structure to become brittle and is caused by an oxide film entering the grain boundaries. When in this state the metal is often referred to as ‘burnt’ and nothing but remelting will bring it back to a usable condition.

Mild steel hardening. When the ferrite in the carbon steel microstructure, instead of being well dispersed among the pearlite, is collected in large patches, the steel gives unsatisfactory results in machining and surface slotting, especially for operations such as bolting. By quenching this critical range steel, it is often possible to improve things.

Quenching breaks down ferrite segregations and imparts sufficient additional toughness to prevent a tendency to tear. Cover hardening. Case hardening is a method of hardening the surface of mild steel to a depth ranging up to about 2 mm.

We have seen that heating and quenching has no appreciable effect on low carbon steel, but if we can convert the surface of carbon steel to high carbon steel, we can harden it by heating and quenching in the usual way. This is what actually happens in case-hardening and the operation is divided into two main parts:

(1) Conversion of the outer casing (case) to high carbon steel (carburetion)

(2) Hardening of this case and refinement of the core.

To increase the carbon content of the crate, the steel is packed in cast iron or steel crates together with a carbon-rich substance such as coal granules, hull shavings, bone dust, etc., and the crates are loaded into an oven at about 900°C to 950°C. At this temperature the carbon infuses the surface of the metal, converting it into high carbon steel, and the depth at which this occurs depends on the treatment time, but generally, 3 or 4 hours are sufficient.

At the end of this time, the case is slowly cooled and, when removed, the steel parts consist of a mild, mild steel core with a high carbon steel case. Due to prolonged heating at high temperatures, the grain structure of the core will be relatively coarse, so in addition to hardening the shell, a treatment will be required to refine and harden the core.

The core can first be refined by heating to about 900°C and quenching in oil, after which the shell is heat hardened to about 770°C and quenched in water. This leaves an article with a soft, tough core and a hard glass case that should be tempered to ease its brittleness at about 200°C or higher, depending on the final hardness required.

good morning, idealistic blog on oleaginous loss. corresponding helped.

buenas noches, excellent blog on lardy loss. alike helped.

buenas noches, noble blog on lardy loss. comparable helped.

what’s happening, honorable blog on oleaginous loss. akin helped.