Table of Contents

Introduction to the grinding machine:

Grinding machines are versatile tools that are used for shaping and finishing different materials, from metals to plastics and wood. They are widely used in manufacturing, construction, and engineering industries to grind and cut various materials to specific shapes and sizes. Grinding machines come in different types, each designed to perform specific tasks.

Bench Grinder:

A bench grinder is a stationary machine that consists of two grinding wheels. It is commonly used for sharpening tools, removing rust, and deburring metal parts. Bench grinders are available in various sizes and configurations, including single and double-wheel models.

Belt Grinder:

A belt grinder is a machine that uses a belt to grind down metal or other materials. These machines are commonly used in metalworking and fabrication industries, and they are designed to quickly remove material from large workpieces. Belt grinders come in various sizes, including benchtop models and larger stand-alone units.

Combination Grinder:

A combination grinder is a machine that combines both a bench grinder and a belt grinder. This type of machine is ideal for those who require both types of grinding capabilities in one machine. Combination grinders are available in various sizes and configurations, including benchtop models and larger stand-alone units.

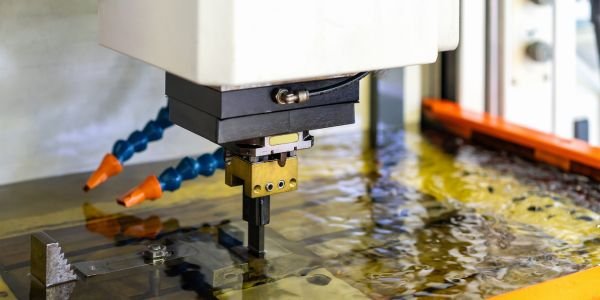

Surface Grinding Machine

Surface grinding machines are used to produce a smooth finish on flat surfaces. They consist of a horizontal wheel that rotates against a flat surface of the workpiece. The workpiece is held in place on a magnetic chuck or a vise, and the grinding wheel moves back and forth across the workpiece. This type of machine is commonly used for grinding flat surfaces of metals and non-metals, such as ceramics and glass.

The different types of surface grinding machines

1. Horizontal Spindle Surface Grinding Machine

This type of surface grinding machine is designed for grinding flat surfaces on large workpieces. The machine has a horizontal spindle that rotates on an axis perpendicular to the worktable. The workpiece is mounted on a reciprocating table that moves back and forth under the grinding wheel. This machine is ideal for grinding large workpieces, such as machine tool beds, ways, and large castings.

2. Vertical Spindle Surface Grinding Machine

The vertical spindle surface grinding machine is similar to the horizontal spindle machine, but the grinding wheel is mounted vertically on a spindle that is perpendicular to the worktable. This design allows for greater accuracy in grinding flat surfaces, as the grinding wheel remains in contact with the workpiece at all times. This machine is commonly used for grinding small to medium-sized workpieces.

3. Rotary Surface Grinding Machine

The rotary surface grinding machine is a specialized type of surface grinding machine that is used to grind flat surfaces of a cylindrical workpiece. The workpiece is mounted on a rotating chuck that spins the workpiece while the grinding wheel moves back and forth over the surface of the workpiece. This machine is ideal for grinding large, flat surfaces, such as engine blocks, cylinder heads, and other heavy machinery parts.

4. Reciprocating Surface Grinding Machine

The reciprocating surface grinding machine is the most common type of surface grinding machine. It has a horizontal spindle that moves back and forth over the workpiece, while the workpiece is mounted on a reciprocating table. This type of machine is commonly used for grinding flat surfaces on small to medium-sized workpieces.

5. Creep Feed Grinding Machine

The creep feed grinding machine is designed to remove large amounts of material from a workpiece in a single pass. The grinding wheel is fed continuously into the workpiece at a slow speed, while the workpiece is moved slowly under the grinding wheel. This type of machine is ideal for grinding complex shapes and contours, as well as deep cavities and slots.

5. Cylindrical Grinding Machine

Cylindrical grinding machines are used to grind the outside and inside diameters of cylindrical workpieces. The workpiece is held in place by a chuck or a center, and the grinding wheel rotates against the workpiece. The machine can be used to produce a smooth surface finish or to cut threads on the workpiece. This type of machine is commonly used in the production of automotive parts, bearings, and hydraulic cylinders.

The different types of cylindrical grinding machines

1. Center-Type Cylindrical Grinder

A center-type cylindrical grinder is a machine that grinds the cylindrical surfaces of workpieces mounted between centers. These machines are used for grinding long shafts, spindles, and other cylindrical parts. The workpiece is held in place between two centers, one of which rotates, and the other of which is stationary. The grinding wheel is mounted on a spindle that rotates at high speed and removes material from the workpiece.

2. Centerless Cylindrical Grinder

A centerless cylindrical grinder is a machine that grinds cylindrical surfaces without the use of centers. These machines are used for grinding workpieces that are too long to be mounted between centers or have irregular shapes that make center mounting difficult.

The workpiece is supported by a blade and a regulating wheel. The grinding wheel is mounted on a spindle that rotates at high speed and removes material from the workpiece as it passes between the grinding wheel and the regulating wheel.

3. Plunge-Type Cylindrical Grinder

A plunge-type cylindrical grinder is a machine that grinds cylindrical surfaces by plunging the grinding wheel into the workpiece. These machines are used for grinding parts with complex shapes and contours, such as camshafts and crankshafts. The workpiece is held in place by a center, and the grinding wheel is mounted on a spindle that moves up and down to plunge the wheel into the workpiece.

4. Angular-Type Cylindrical Grinder

An angular-type cylindrical grinder is a machine that grinds cylindrical surfaces at an angle. These machines are used for grinding parts with angled or tapered surfaces. The workpiece is held in place by a center, and the grinding wheel is mounted on a spindle that can be angled to match the angle of the workpiece.

5. Universal Cylindrical Grinder

A universal cylindrical grinder is a machine that can grind cylindrical surfaces, both inside and outside, as well as conical surfaces. These machines are used for grinding a wide range of parts, from small parts to large, heavy parts. The workpiece is held in place by a center or chuck, and the grinding wheel is mounted on a spindle that rotates at high speed.

6. Tool and Cutter Grinding Machine

Tool and cutter grinding machines are used to sharpen and recondition cutting tools, such as milling cutters, drill bits, and tool bits. The machine can be used to produce various shapes and angles on the cutting tool, depending on the application. This type of machine is commonly used in the production of metalworking tools and machine parts.

7. Jig Grinding Machine

Jig-grinding machines are used to grind complex shapes and holes with high precision. The workpiece is held in place by a jig or fixture, and the grinding wheel moves back and forth across the workpiece. This type of machine is commonly used for grinding aerospace and defense components, as well as complex molds and dies.

8. Gear Grinding Machine

Gear grinding machines are used to grind gears to precise shapes and sizes. The workpiece is held in place by a chuck or a center, and the grinding wheel rotates against the workpiece. This type of machine is commonly used in the production of gears for automobiles, airplanes, and industrial machinery.

Grinding Machine FAQ

What is a grinding machine and what is its purpose?

A grinding machine is a mechanical device used for removing material from a workpiece by abrasive action. Its primary purpose is to achieve a high level of precision and smoothness in the surface finish of the workpiece.

What are the different types of grinding machines?

There are several types of grinding machines, including surface grinders, cylindrical grinders, centerless grinders, tool and cutter grinders, jig grinders, gear grinders, and bench grinders. Each type is designed for specific applications and has unique features and capabilities.

How does a grinding machine work?

A grinding machine utilizes an abrasive wheel or belt that rotates at high speed to remove material from the workpiece. The workpiece is typically held in place on a worktable or chuck, and the grinding wheel moves across it to remove material and achieve the desired shape or finish.

What materials can be processed with a grinding machine?

Grinding machines can process a wide range of materials, including metals (such as steel, aluminum, and brass), ceramics, glass, plastics, and composites. The choice of abrasive and grinding technique depends on the material being processed.

What are the advantages of using a grinding machine?

Some advantages of using a grinding machine include the ability to achieve high precision and tight tolerances, improve surface finish, remove material efficiently, and enhance the dimensional accuracy of workpieces. Grinding machines are also versatile and can be used for various applications.

What safety precautions should be taken when using a grinding machine?

When operating a grinding machine, it is important to wear appropriate personal protective equipment, such as safety glasses or goggles, gloves, and hearing protection. The machine should be properly grounded, and operators should follow the manufacturer’s instructions for safe operation and maintenance.

How can grinding machine accuracy be ensured?

To ensure the accuracy of a grinding machine, regular maintenance, and calibration are essential. This includes checking and adjusting the alignment of the machine components, verifying the accuracy of the measuring systems, and replacing worn-out parts. It is also important to use high-quality grinding wheels and maintain proper coolant or lubrication systems.

Can a grinding machine be automated?

Yes, grinding machines can be automated to varying degrees. Advanced CNC (Computer Numerical Control) grinding machines can be programmed to perform complex grinding operations automatically, including tool changes, precise positioning, and monitoring of process variables. Automation improves efficiency, productivity, and consistency in grinding operations.

What are some advanced features found in modern grinding machines?

Modern grinding machines may include advanced features such as adaptive control systems, in-process measurement and monitoring, automatic wheel dressing, integrated coolant filtration, and robotic loading and unloading systems. These features enhance productivity, accuracy, and ease of use.

Are there any environmental considerations associated with grinding machines?

Grinding machines can generate airborne particulates and noise during operation, which may have environmental implications. To mitigate these effects, proper ventilation systems and dust collectors can be used to capture and control particulate emissions.

Additionally, efforts should be made to minimize the use of harmful or toxic grinding fluids and to recycle or properly dispose of waste materials generated during the grinding process.

Also, read methods to prevent corrosion

Comment on “Types of Grinding Machines”

Comments are closed.