Table of Contents

Electrical Discharge Machining, or EDM for short, is a non-traditional machining process that utilizes electrical sparks to remove material from a workpiece, thereby forming a desired shape. Over the past several decades, EDM has found its place in the manufacturing industry because of its ability to machine complex geometries in hard materials.

History of EDM

EDM’s history traces back to the 1940s when the process was first introduced to make hardened molds. The initial technology was a bit rudimentary, primarily because it was a byproduct of investigating ways to remove broken drills and taps from hardened steel. The potential for more evolved applications quickly became evident, leading to the development of more refined and efficient EDM machines over time.

Construction or parts of EDM Machine:

- Power Supply Unit:

- The heart of the EDM machine provides the controlled electrical power needed for the sparking process.

- Converts AC voltage from the main supply into a DC voltage. This DC voltage is then used to generate controlled pulses of current.

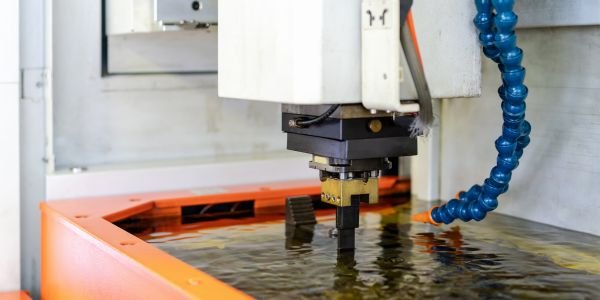

- Dielectric System:

- Consists of a dielectric tank, pump, filtering system, and the dielectric fluid (commonly deionized water or special EDM oils).

- The dielectric fluid acts as an insulator until the voltage reaches a point where ionization occurs. Once ionization occurs, it becomes a conductor, allowing the spark to jump.

- It also helps cool both the workpiece and the electrode, and it flushes away the eroded debris.

- Electrode (Tool) and Tool Holder:

- The electrode is typically made from graphite, copper, or tungsten. Its shape often corresponds to the desired shape in the workpiece.

- The tool holder holds the electrode in position and may have provisions for moving the electrode in a controlled manner.

- Workpiece and Work Table:

- The workpiece is the part being machined.

- It’s mounted on a table that can be moved in at least three directions (X, Y, Z axes). Some advanced machines can also move in rotary or tilting axes.

- Servo Control System:

- It controls the gap between the electrode and the workpiece.

- Maintains optimal sparking conditions by adjusting the position of the electrode as it wears and as the material is eroded from the workpiece.

- Control Panel:

- This is where the operator inputs settings and controls the operation of the machine.

- Modern EDMs have Computer Numerical Control (CNC) systems that allow for high precision and can follow complex machining paths based on CAD/CAM data.

- Filtering System:

- This system filters the dielectric fluid to remove the particles that result from the machining process.

- Ensuring the fluid is clean helps in achieving a stable sparking condition and a better surface finish.

- Cooling System:

- EDM processes generate heat at the sparking site. A cooling system, often using coolants, helps dissipate this heat and keeps the machine at an optimal temperature.

- Safety Systems:

- Most EDM machines are equipped with safety interlocks and emergency stop buttons.

- Over-temperature, over-voltage, and over-current protection systems are also often present.

- Cabinet:

- Houses the various components and systems.

- Provides a stable structure and may have doors or panels for easy access for maintenance.

Here’s an important table summarizing key parameters and features of an EDM machine:

| Feature/Parameter | Description/Function | Typical Values/Examples |

| Power Supply Type | Type of electrical power supplied to generate controlled pulses | DC Power Supply |

| Dielectric Fluid | Fluid used to facilitate the spark and remove heat and debris | Deionized Water, EDM Oil |

| Electrode Material | The ratio of the active period of the pulse to its total period | Graphite, Copper, Tungsten |

| Max. Current | The maximum electrical current the machine can handle | 30 A, 50 A, 100 A |

| Voltage | The typical operating voltage | 40-150 V |

| Duty Cycle | The time length of each electrical pulse | 50%, 70%, 90% |

| Pulse Duration | Time length of each electrical pulse | 50 µs, 100 µs |

| Max. Workpiece Size | The maximum size of the workpiece the machine can accommodate | 400x300x200 mm (varies) |

| Table Travel (X, Y, Z) | The range of motion for each axis | 300x200x250 mm (varies) |

| Surface Finish | The smoothness of the machined surface, usually measured in Ra (roughness average) | 0.1 µm Ra, 0.5 µm Ra |

| Electrode Wear Rate | How quickly the electrode material erodes during the process | 0.1%, 0.5% |

| Material Removal Rate | The rate at which material is eroded from the workpiece | 500 mm³/min, 1000 mm³/min |

| Cooling System | Mechanism for dissipating heat generated during the process | Water-cooled, Oil-cooled |

| Control System | The system controlling the machine operations | CNC, Manual |

| Safety Features | The material of the tool used to erode the workpiece | Emergency stop, Over-current protection |

Note: This table is a general summary. Specific EDM machines will have values and features that vary based on the model, manufacturer, and intended use. Always consult the machine’s specifications and user manual for precise details.

Types of EDM Machines

Broadly, EDM machines can be categorized into two types:

- Die Sinking EDM Machines (or Conventional EDM Machines):

- Used to machine complex cavities and shapes in dies and molds.

- Also known as ram EDM or spark EDM.

- Uses an electrode and workpiece submerged in a dielectric fluid.

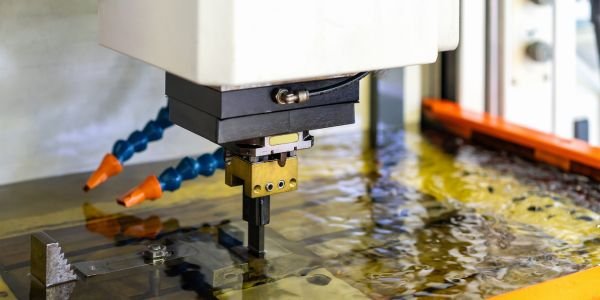

- Wire EDM Machines:

- Uses a continuous wire as the electrode.

- Primarily used for making punch and die combinations for die sets and contouring.

- Has the capability to cut intricate contours or cavities in pre-hardened steel without the need for heat treatment.

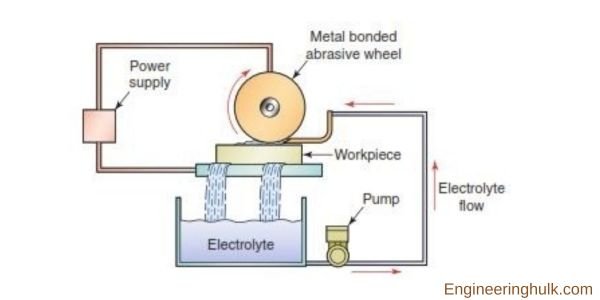

Working Principle of EDM

EDM is based on thermoelectric energy between a workpiece and an electrode. Here’s a step-by-step breakdown:

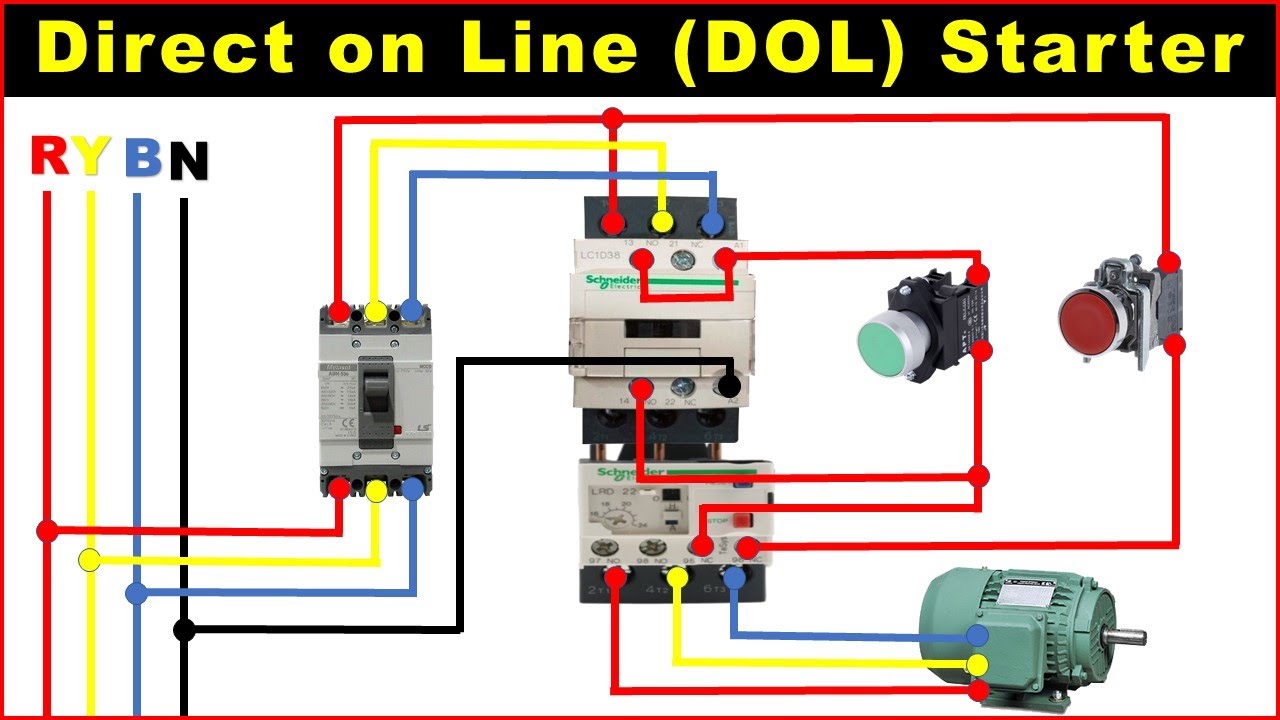

- Electrode and Workpiece Setup: Both the electrode and the workpiece are connected to a direct current power supply, with the workpiece being the positive pole and the electrode being the negative pole.

- Creation of the Spark: As the electrode approaches the workpiece, the dielectric fluid (usually deionized water or hydrocarbon oil) in between gets ionized, and a spark jumps through this ionized channel.

- Material Erosion: The high-temperature spark (which can reach temperatures up to 12,000°C) melts and evaporates a small portion of the workpiece, creating a tiny crater. This process is repeated multiple times per second.

- Flushing of Melted Material: The dielectric fluid helps in flushing away the melted material, ensuring the machining area is clear for subsequent sparks.

Advantages of EDM

- Machining Hardened Materials: EDM can easily machine hardened materials, eliminating the need for post-machining heat treatment.

- Complex Shapes: It can produce intricate and detailed shapes that are difficult to achieve with traditional machining processes.

- Fine Finish: With the right settings, EDM can deliver a very smooth finish.

- No Direct Contact: Since the cutting action of EDM is achieved by sparks, the electrode never makes direct contact with the workpiece. This reduces the risk of tool wear and breakage.

- Low Residual Stresses: Due to the non-mechanical nature of EDM, the residual stresses introduced into the workpiece are minimal.

Applications of EDM

- Aerospace and Defense: Manufacturing of turbine blades, jet engine components, and other intricate parts.

- Medical: Production of components like surgical instruments, dental prostheses, and even components for heart pacemakers.

- Tool and Die Production: For making mold cavities, forging dies, extrusion dies, and more.

- Automotive: Production of small components for engines and other intricate parts.

- Prototype Production: EDM is especially valuable for prototyping because it can produce complex shapes in a single setup.

Limitations and Considerations

- Material Limitation: Both the workpiece and the electrode need to be conductive.

- Slow Removal Rate: Compared to other machining processes, EDM’s material removal rate is relatively slow.

- Overcut: Due to the sparking action, EDM always results in an overcut. Accurate dimensions require taking this into account during the process setup.

- Surface Finish Variability: While EDM can produce a fine finish, the resulting surface can be varied, often requiring additional finishing operations.

- Electrode Wear: In die-sinking EDM, the electrode wears with use, so multiple electrodes might be required for longer runs.

EDM has proven itself to be an invaluable tool in modern manufacturing. Its ability to handle hardened materials and produce intricate shapes makes it a preferred choice for many industries. While it does have its limitations, advancements in technology and refined techniques are continually expanding EDM’s potential applications and improving its efficiency.

By understanding the workings, benefits, and applications of EDM, manufacturers, and engineers can better harness this unique machining process, pushing the boundaries of what’s possible in production and design. Whether you’re producing intricate medical devices or aerospace components, EDM offers a unique set of advantages that make it a worthy addition to any manufacturer’s toolkit.

Also, read Non-Destructive Testing