Table of Contents

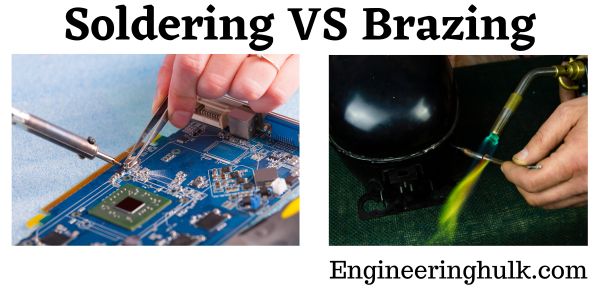

Soldering:

Soldering is a process that involves melting a filler material, known as solder, and applying it to the metal parts to be joined. The solder used in soldering is typically a mixture of tin and lead, although other materials such as silver, copper, and zinc can also be used. Soldering is a low-temperature process, usually performed at temperatures between 200 and 400 degrees Celsius.

One of the advantages of soldering is that it can be used to join a wide variety of metals, including brass, copper, aluminum, and stainless steel. Soldering is also a relatively fast process, and it does not require a lot of equipment. However, soldered joints are generally not as strong as brazed joints and may be more prone to failure under stress.

Brazing:

Brazing is a process that involves melting a filler material, known as braze and applying it to the metal parts to be joined. The braze used in brazing is typically a mixture of copper and zinc, although other materials such as silver, nickel, and aluminum can also be used. Brazing is a high-temperature process, usually performed at temperatures between 600 and 900 degrees Celsius.

One of the main advantages of brazing is that it produces very strong joints that are resistant to stress and vibration. Brazed joints are also more durable than soldered joints and can withstand higher temperatures. However, brazing requires more specialized equipment than soldering and is generally a slower process.

Key Differences:

The main differences between soldering and brazing can be summarized as follows:

1. Temperature:

Soldering is a low-temperature process, while brazing is a high-temperature process.

2. Strength:

Brazed joints are generally stronger than soldered joints and can withstand more stress.

3. Durability:

Brazed joints are more durable than soldered joints and can withstand higher temperatures.

4. Equipment:

Brazing requires more specialized equipment than soldering.

5. Materials:

Soldering can be used to join a wider variety of metals than brazing.

Soldering vs. Brazing

Soldering and brazing are both techniques used for joining metals, but they differ in their melting temperatures and the materials used. Soldering typically involves the use of a low-melting-point alloy, while brazing involves a higher-melting-point alloy.

Soldering is often used for electrical work, plumbing, and jewelry making. The solder is melted using a soldering iron and then flows into the joint between the two pieces of metal. Solder typically melts at temperatures below 800 degrees Fahrenheit (427 degrees Celsius).

Brazing, on the other hand, is used for heavier-duty applications, such as in the automotive and aerospace industries. The brazing alloy is melted using a torch and then flows into the joint between the two pieces of metal. Brazing typically involves melting the alloy at temperatures above 800 degrees Fahrenheit (427 degrees Celsius).

Soldering and Brazing Comparison Chart

To help you understand the differences between soldering and brazing, I have created a comparison chart that outlines the key differences between the two techniques.

| Feature | Soldering | Brazing |

| Melting Temperature | Below 800°F (427°C) | Above 800°F (427°C) |

| Joint Strength | Weaker than brazing | Stronger than soldering |

| Materials Used | Low-melting-point alloy | High-melting-point alloy |

| Equipment Needed | Soldering iron | Torch |

| Applications | Electrical work, plumbing, jewelry making | Automotive, aerospace, heavy-duty applications |

As you can see from the chart, soldering, and brazing have some key differences. Soldering is generally used for lighter-duty applications, while brazing is used for heavier-duty applications that require a stronger joint. Brazing also requires a torch, while soldering only requires a soldering iron.

When to Use Soldering vs. Brazing

When deciding whether to use soldering or brazing, it’s important to consider the materials you are working with and the application. Soldering is ideal for lighter-duty applications, such as electrical work, plumbing, and jewelry making. Brazing is better suited for heavy-duty applications, such as in the automotive and aerospace industries.

In addition to the application, the materials you are working with can also play a role in determining whether to use soldering or brazing. If you are working with materials that have a low melting point, such as tin or lead, soldering may be the better option. If you are working with materials that have a higher melting point, such as steel or copper, brazing may be the better option.

Comment on “Difference between soldering and brazing”

Comments are closed.