Table of Contents

Manometer Introduction:

Manometers are devices that measure fluid pressure, typically using a column of liquid. They have a variety of applications, including in industrial processes, HVAC systems, and medical equipment.

What is a manometer?

A manometer is a device used to measure pressure. It consists of a U-shaped tube filled with a liquid, usually mercury, water, or oil. The tube is open at both ends and is connected to the system being measured. The pressure is measured by the difference in height between the two columns of liquid in the tube.

Types of manometers:

There are many types of manometers, each with its own advantages and disadvantages. The most common types include:

1. U-tube manometer: This is the most basic type of manometer and consists of a U-shaped tube filled with a liquid. It is simple, inexpensive, and can be used to measure both positive and negative pressures.

2. Inclined manometer: This type of manometer is similar to the U-tube manometer but is tilted at an angle. It is often used to measure low-pressure differentials.

3. Digital manometer: This type of manometer uses electronic sensors to measure pressure. It is more accurate and precise than other types of manometers but is also more expensive.

4. Bourdon tube manometer: This type of manometer uses a metal tube that is curved into a C-shape. The pressure causes the tube to straighten, which is then used to measure the pressure.

Working Principle of a Manometer

A manometer works on the principle of hydrostatics, which is the study of fluids at rest. The pressure exerted by a fluid at a particular point is transmitted equally in all directions. This means that the pressure at the bottom of a fluid column is greater than the pressure at the top of the column. The pressure difference between two points in a fluid is proportional to the height difference between the two points.

A manometer consists of a U-shaped glass tube filled with a liquid, usually mercury or water. The two arms of the tube are vertical and connected to the source of pressure at one end and open to the atmosphere at the other end. When pressure is applied to one arm of the tube, the liquid in that arm is displaced and rises in the tube. The level of the liquid in the other arm of the tube drops, as a result of the pressure difference.

The difference in the levels of the liquid in the two arms of the U-tube is proportional to the pressure difference between the two points. This is known as the height of the manometer.

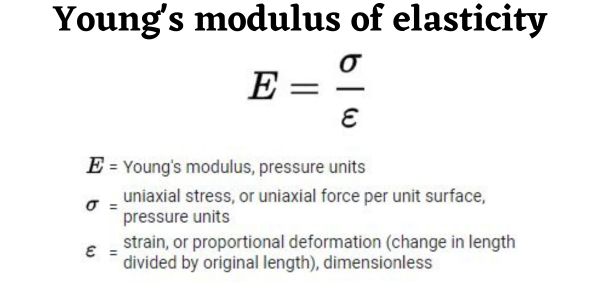

The pressure difference is calculated using the formula:

P = ρgh

where P is the pressure difference, ρ is the density of the liquid, g is the acceleration due to gravity, and h is the height of the liquid column.

What are the units of a manometer?

There are three primary units of pressure measurement in manometers, which are as follows:

1. Pascal (Pa): The Pascal is the International System of Units (SI) unit of pressure. One Pascal is equal to one Newton per square meter (N/m2). This is a small unit of pressure, and it is often used to measure very low pressures. For example, a typical atmospheric pressure is around 101,325 Pa.

2. Bar (bar): The bar is a unit of pressure commonly used in the metric system. One bar is equal to 100,000 Pa or 1,000 hPa. It is often used in the industrial sector to measure high pressures. For example, the pressure in a gas pipeline can be several bars.

3. Torr (Torr): The Torr is a non-SI unit of pressure. It is also known as a millimeter of mercury (mmHg) as it is the pressure exerted by a column of mercury that is 1 millimeter high. One Torr is equal to 133.3224 Pa. It is often used in vacuum measurements and in the medical industry to measure blood pressure.

Apart from these primary units, there are other units of pressure that are sometimes used in manometers, such as pounds per square inch (psi) and atmospheres (atm). However, these units are not commonly used in manometers, and the primary units discussed above are more widely used.

What is a manometer used for?

Manometers are widely used in various industries for measuring pressure, vacuum, and differential pressure. These devices are simple and cost-effective tools that can measure a wide range of pressures accurately. Manometers come in different types, such as U-tube, inclined, and digital manometers, each with its own specific use.

1. HVAC Industry:

Manometers are commonly used in the HVAC industry for measuring pressure in air ducts, ventilation systems, and other HVAC components. They are used to measure airflow, static pressure, and differential pressure, and can help diagnose problems such as blocked air filters or duct leaks.

2. Gas and Oil Industry:

In the gas and oil industry, manometers are used to measure the pressure of gases and liquids in pipelines, tanks, and other equipment. Accurate pressure measurement is critical for maintaining the safe operation of these systems, and manometers are often used as part of the routine maintenance and testing process.

3. Pharmaceutical Industry:

In the pharmaceutical industry, manometers are used to measure the pressure of gases and liquids in various manufacturing processes. They are used to ensure that the pressure is consistent throughout the process and that the quality of the final product is consistent.

4. Manufacturing Industry:

Manometers are used in the manufacturing industry to monitor and control various production processes. They are used to measure the pressure of gasses and liquids in various stages of production, including molding, forming, and casting processes. Manometers can help ensure that the quality of the final product is consistent and that production processes are operating efficiently.

5. Aerospace Industry:

Manometers are used in the aerospace industry for various applications, including measuring the pressure of gasses in engines, testing the pressure in aircraft cabin pressurization systems, and measuring the pressure of fluids in hydraulic systems. Accurate pressure measurement is critical for the safe and reliable operation of aircraft, and manometers play an important role in maintaining these systems.

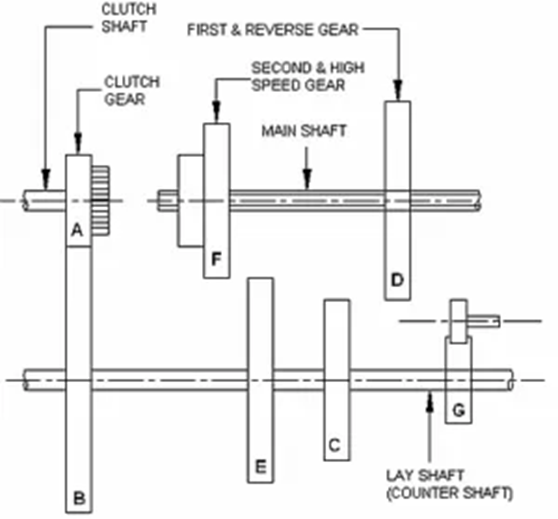

6. Automotive Industry:

In the automotive industry, manometers are used to measure the pressure of fluids in various components, such as brake systems and transmissions. They are also used to measure the pressure of gases in engines and exhaust systems and can help diagnose problems such as engine misfires or leaks in the exhaust system.

7. Medical Industry:

Manometers are used in the medical industry for various applications, including measuring blood pressure and monitoring the pressure of gases in anesthesia machines. Accurate pressure measurement is critical for patient safety, and manometers are often used as part of routine medical procedures.

References

- Mehta, S., & Mehta, R. (2017). A review on manometer: principles, types and applications. International Journal of Research in Engineering and Applied Sciences, 7(5), 45-50.

- Gopalakrishnan, V., & Viswanathan, V. (2018). An experimental study of manometer types and applications. Journal of Applied Science and Engineering, 21(3), 439-445.

- Ali, M. S., Hassan, M. Z., & Ismail, I. (2020). Advancements in manometer technology: A comprehensive review. Measurement, 165, 108058.

- Bhatnagar, A., & Singh, A. K. (2019). Review on advancements in manometer technology for pressure measurement. International Journal of Scientific Research in Science, Engineering and Technology, 5(2), 269-275.

- ASTM International. (2019). ASTM E171-19: Standard Practice for Conditioning and Testing Flexible Barrier Packaging. ASTM International. [Online]. Available: https://www.astm.org/Standards/E171.htm

Also, read Types of welding

Comment on “Manometer – Definition, Types & Working Principle”

Comments are closed.