Table of Contents

Introduction

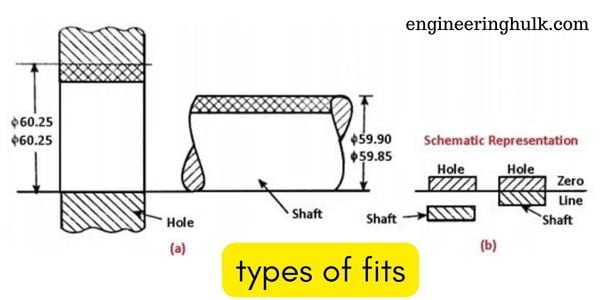

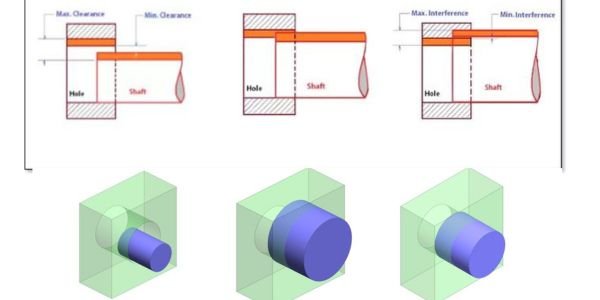

Fits play a vital role in ensuring the proper assembly and functionality of mechanical systems. Fits describe the relationship between two mating parts, such as holes and shafts, and determine the amount of clearance or interference between them.

What are Fits in Engineering?

Fits in engineering refer to the dimensional relationship between two mating parts, such as a hole and a shaft. It describes the amount of clearance or interference between these components. The selection of an appropriate fit is essential for ensuring optimal performance, alignment, load-bearing capacity, and durability of mechanical systems.

Example: Hole and Shaft Fits

Let’s consider the example of a hole and a shaft to better understand the concept of fits in engineering.

a. Clearance Fit:

A clearance fit occurs when the hole is larger than the shaft, resulting in intentional clearance between the mating parts. This fit type allows relative movement between the hole and the shaft. It is commonly used when ease of assembly, disassembly, or interchangeability is required. For instance, a clearance fit may be suitable for connecting a drive shaft to a gear, where some level of movement is necessary.

b. Interference Fit:

An interference fit exists when the hole is smaller than the shaft, causing intentional interference or overlap between the mating parts. This fit type ensures a tight, secure, and rigid connection without the need for additional fasteners. Interference fits are often used in applications where slippage prevention, increased load-bearing capacity, or enhanced alignment is required.

For example, press-fitting a bearing into a housing creates an interference fit, ensuring a secure and reliable connection.

c. Transition Fit:

A transition fit represents a combination of clearance and interference fits. It allows for a controlled amount of clearance and interference simultaneously. This type of fit is typically used when a balance between clearance and interference is required for specific applications.

Transition fits are often used to achieve the desired level of friction or compensate for thermal expansion. An example of a transition fit is the connection between a piston and cylinder in an internal combustion engine.

Importance of Proper Fit Selection

Choosing the right fit for a hole and shaft assembly is crucial for several reasons:

a. Functional Performance:

The selection of an appropriate fit directly impacts the functional performance of the mechanical system. A well-chosen fit ensures smooth operation, prevents excessive play or binding, and allows for the desired level of movement or rigidity between the components.

b. Load-Bearing Capacity:

The fit type influences the load-bearing capacity of the assembly. An interference fit can increase the strength and load-carrying capabilities of the connection, whereas a clearance fit may allow for easier disassembly or adjustment.

c. Alignment and Precision:

Proper fit selection helps maintain alignment and precision in mechanical systems. The right fit minimizes misalignment, reduces vibration, and enhances overall accuracy.

d. Environmental Considerations:

The choice of fit should also consider environmental factors such as temperature fluctuations, exposure to humidity or corrosive substances, and the presence of contaminants. These factors can impact the dimensional stability and performance of the fit over time.

Factors Influencing Fit Selection

Several factors influence the selection of an appropriate fit for a hole and shaft assembly:

a. Functional Requirements:

Consider the specific function and purpose of the assembly. Determine whether a clearance fit, interference fit, or transition fit best aligns with the desired performance and functionality of the mechanical system.

b. Material Properties:

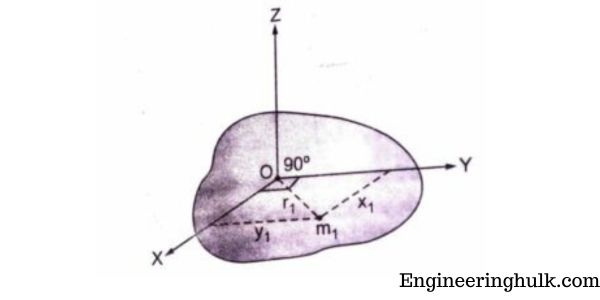

The material properties of the hole and shaft, such as thermal expansion coefficient, hardness, and surface finish, can impact the fit selection. Different materials exhibit varying levels of dimensional changes due to temperature fluctuations, which should be considered to ensure a proper fit.

c. Manufacturing Process:

The manufacturing process used to produce the hole and shaft can influence fit selection. Processes like drilling, reaming, or machining can introduce dimensional variations that should be accounted for when determining the fit type.

d. Assembly Method:

Consider the assembly method and available tools or equipment. Some fits may require specific techniques or machinery for proper assembly, while others may offer easier disassembly or adjustment.

FAQ

What are the primary types of fits in engineering and manufacturing?

In engineering and manufacturing, the primary types of fits are categorized into three classes: clearance fit, interference fit, and transition fit.

What is a clearance fit, and when is it preferred in design?

A clearance fit is a type of fit where the maximum shaft size is always smaller than the minimum hole size. It results in a gap between the shaft and the hole, allowing for relative movement or assembly of parts. It is preferred when ease of assembly and disassembly is necessary, or when there is a need for tolerance between mating parts.

Explain the concept of an interference fit and its typical applications.

An interference fit is a type of fit where the minimum shaft size is always larger than the maximum hole size. This fit creates a compression force between the parts, holding them together without the need for additional fasteners. Interference fits are commonly used in press-fit connections, bearings, and high-stress applications where a rigid joint is required.

What is a transition fit, and when is it used?

A transition fit is a type of fit that falls between clearance and interference fits. In this fit, the shaft size is slightly larger than the hole size, resulting in either a slight interference or clearance depending on the actual dimensions. Transition fits are often used when a compromise between clearance and interference is needed, allowing some movement while maintaining a controlled amount of force transmission.

Also, read Types of Pumps

Comment on “Types of Fits in Engineering – 2023 Guide”

Comments are closed.