Table of Contents

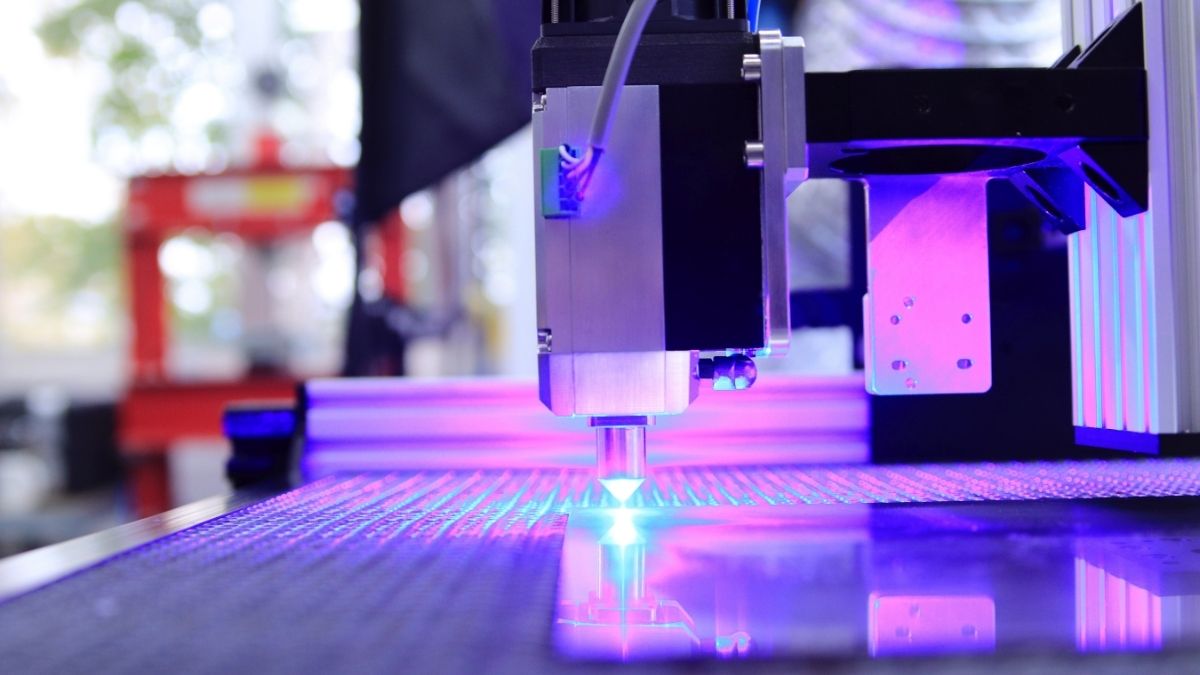

Welding is a centuries-old craft that has evolved significantly over time, with numerous techniques and methods developed to meet the ever-increasing demands of various industries. One such technique that has gained immense popularity is Metal Inert Gas (MIG) welding.

What is Metal Inert Gas (MIG) Welding?

Metal Inert Gas (MIG) welding, also known as Gas Metal Arc Welding (GMAW), is a welding process that uses a continuous consumable electrode wire, an inert or semi-inert gas, and an electric arc to join metals together. It is one of the most commonly used welding methods in various industries due to its versatility and ease of use.

Understanding the MIG Basics

The Origins of MIG Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), was developed during the early 1940s by a team of researchers at the Battelle Memorial Institute in Columbus, Ohio. This innovative technique was initially used in World War II for welding aluminum and other non-ferrous metals, which were essential in aircraft construction. Since then, MIG welding has become an indispensable method in various industries, including automotive, construction, and manufacturing.

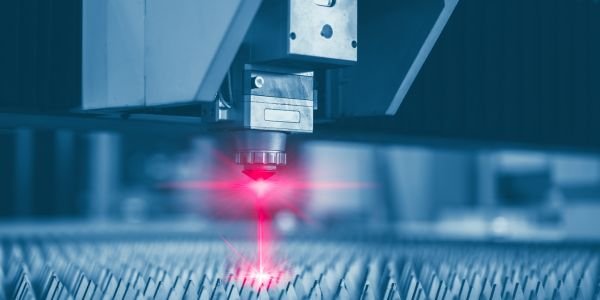

How MIG Welding Works

Here’s an overview of how MIG welding works:

- Setup and Equipment:

- MIG welding requires a welding machine that can generate a direct current (DC) electrical arc.

- A gas cylinder containing a shielding gas, typically a mixture of argon and carbon dioxide or 100% carbon dioxide, is connected to the welding machine.

- A spool of consumable welding wire, which is often made of the same metal as the workpiece or a compatible alloy, is attached to the welding gun.

- Electrical Circuit:

- When the welding machine is turned on, it generates an electrical circuit. The wire electrode is connected to the positive terminal of the machine, while the workpiece is connected to the negative terminal.

- Shielding Gas Flow:

- The flow of shielding gas is initiated, creating a protective atmosphere around the welding area. This gas prevents atmospheric contaminants (like oxygen and nitrogen) from coming into contact with the molten metal, which could lead to impurities and poor weld quality.

- Triggering the Arc:

- The welder holds the welding gun with the electrode close to the workpiece.

- When the trigger on the gun is pulled, an electrical circuit is completed, and a high-voltage current flows through the wire electrode.

- This electrical current creates an arc, which is a highly concentrated heat source, and it also melts the tip of the wire electrode.

- Melting and Welding:

- The intense heat from the arc melts both the wire electrode and the workpiece in the immediate vicinity of the arc.

- As the wire electrode continuously feeds into the weld zone, it deposits molten metal onto the joint, effectively joining the pieces together.

- Weld Pool and Solidification:

- The molten metal forms a weld pool that cools and solidifies as the arc progresses along the joint.

- The shielding gas continues to protect the weld pool until it solidifies, preventing contamination.

- Weld Bead Formation:

- The welder controls the welding gun’s movement speed and direction to create the desired weld bead shape and size.

- By adjusting the wire feed rate, voltage, and amperage, the welder can control the heat input and penetration depth, allowing for precise control of the welding process.

- Cooling and Inspection:

- After completing the weld, the workpiece is allowed to cool naturally or may be quenched in water, depending on the specific welding requirements.

- The quality of the weld is visually inspected, and any necessary post-weld treatments, such as grinding or additional passes, are performed to achieve the desired weld characteristics.

Essential Equipment

To get started with MIG welding, you’ll need a set of essential equipment:

Welding Machine

A MIG welding machine, also known as a welder or power source, generates the electric current required for welding. These machines vary in size and capability, so choose one that suits your specific welding needs.

Wire Feeder

A wire feeder is an integral part of the MIG welding setup. It feeds the welding wire from a spool to the welding torch at a controlled rate, ensuring a consistent weld bead.

Welding Torch

The welding torch is where the magic happens. It holds the electrode wire and directs the flow of shielding gas, allowing you to control the welding process accurately.

Welding Wire

Selecting the right welding wire is crucial for achieving the desired results. The type of wire you choose depends on the material you intend to weld. Common options include mild steel, stainless steel, and aluminum wire.

Shielding Gas

The choice of shielding gas depends on the materials and welding process. Argon, carbon dioxide, and a combination of the two are commonly used gases. Consult with your welding supply store to determine the most suitable gas for your project.

Personal Protective Equipment (PPE)

Safety is paramount in welding. Always wear appropriate PPE, including a welding helmet with a darkened visor, flame-resistant clothing, gloves, and safety glasses.

Mastering the Techniques

Setting Up Your Machine

Before you start welding, ensure that your welding machine is correctly set up. This involves adjusting the wire speed, voltage, and gas flow rate to match the material thickness and type of wire being used. Consult your machine’s manual for specific guidance on these settings.

Preparing the Workpiece

Proper preparation of the workpiece is essential for successful MIG welding. Clean the surface of the metal to remove any contaminants, rust, or paint. Ensure that the metal pieces to be joined are properly aligned and clamped securely in place.

Striking the Arc

To start welding, you’ll need to strike an arc. This is done by bringing the welding torch close to the workpiece and initiating the wire feed. As the wire touches the metal, the electric arc is created. Maintain a steady hand and a consistent travel speed to achieve a uniform weld bead.

Welding Techniques

There are various welding techniques you can employ, depending on your project requirements. These include the straight-line technique, weave technique, and circular technique. Each technique has its unique characteristics and applications.

Monitoring and Adjusting

While welding, pay close attention to the appearance of the weld pool and the sound of the arc. Adjust the welding parameters as needed to achieve the desired bead profile and penetration depth.

Safety First

MIG welding involves high temperatures, sparks, and potentially hazardous fumes. Always prioritize safety by following these guidelines:

- Wear Appropriate PPE: Ensure you have the right protective gear, including a welding helmet, gloves, and flame-resistant clothing.

- Work in a Well-Ventilated Area: Welding generates fumes that can be harmful if inhaled. Perform welding in an area with good ventilation or consider using a welding fume extractor.

- Fire Safety: Keep a fire extinguisher nearby and be vigilant about preventing sparks from igniting flammable materials.

- Electricity Safety: Be aware of electrical hazards and follow safety procedures to prevent electrical shocks.

- Proper Training: If you’re new to welding, seek proper training and supervision from an experienced welder.

Applications of MIG Welding

MIG welding is a versatile technique widely used across various industries for different applications:

- Automotive: MIG welding is extensively used in the automotive industry for manufacturing, repairs, and customizations.

- Construction: It plays a crucial role in the construction of buildings and infrastructure, including welding structural steel and pipelines.

- Manufacturing: MIG welding is essential for creating durable and precise welds in manufacturing processes for a wide range of products.

- DIY and Hobbyist Projects: Many DIY enthusiasts and hobbyists use MIG welding for creating custom metal projects and artwork.

MIG welding is a powerful and versatile welding technique that has revolutionized industries and enabled countless projects to come to life. Whether you’re a professional welder or a DIY enthusiast, mastering the art of MIG welding can open up a world of possibilities.

Prioritize safety, invest in quality equipment, and practice your techniques to achieve consistently high-quality welds. With dedication and practice, you can become a MIG welding expert and tackle a wide range of projects with confidence.

Also, read eddy current

Comments on “Metal Inert Gas (MIG) Welding: A Comprehensive Guide”

Comments are closed.