Table of Contents

Introduction

Laser etching machines are devices that use a laser beam to create precise and intricate designs on a variety of materials. These machines have become increasingly popular in recent years due to their ability to produce high-quality results quickly and efficiently.

What is a Laser Etching Machine?

A laser etching machine is a piece of equipment that uses a high-powered laser beam to create precise and permanent markings on a variety of materials. The laser beam is focused onto the surface of the material, causing it to vaporize and create a permanent mark. Laser etching machines are commonly used in the manufacturing industry for labeling and branding products, creating serial numbers, and marking logos.

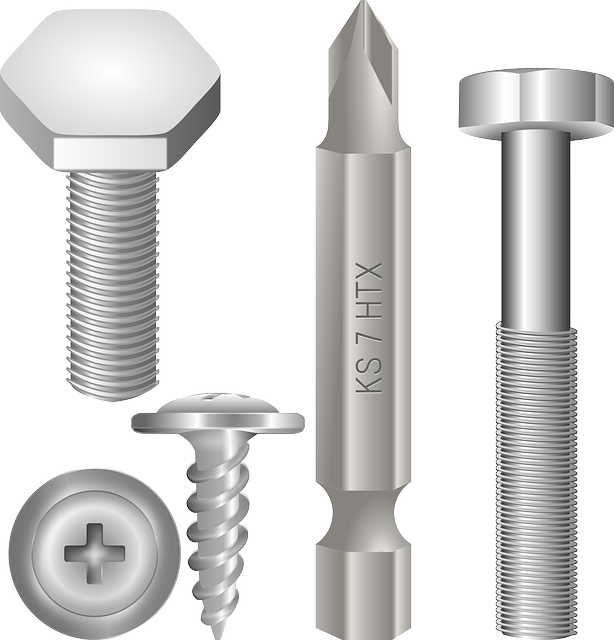

Parts of a Laser Etching Machine

Laser etching machines are made up of several parts, each of which plays a crucial role in the etching process. Here are the main parts of a laser etching machine:

1. Laser Source –

The laser source is the heart of the laser etching machine. It produces a high-powered laser beam that is used to etch the material.

2. Beam Delivery System –

The beam delivery system is responsible for delivering the laser beam from the laser source to the material being etched. It typically consists of mirrors and lenses that help to focus and direct the beam.

3. Controller –

The controller is the brain of the laser etching machine. It is responsible for controlling the movement of the beam delivery system and the intensity of the laser beam.

4. Work Surface –

The work surface is the area where the material being etched is placed. It is typically made of a durable material such as steel or granite.

5. Exhaust System –

The exhaust system is used to remove any fumes or debris created during the etching process. It typically consists of a fan and a filter system.

Working of a Laser Etching Machine

The laser etching process begins with the preparation of the material being etched. The surface of the material is cleaned and prepared to ensure that the etching will be precise and permanent.

Once the material is prepared, it is placed on the work surface of the laser etching machine. The controller is used to set the parameters for the etching, including the depth, speed, and intensity of the laser beam.

The laser beam is then directed onto the surface of the material using the beam delivery system. As the beam moves across the surface, it vaporizes the material, creating a permanent mark. The exhaust system removes any fumes or debris created during the etching process.

Once the etching is complete, the material is removed from the work surface and inspected to ensure that the marking is precise and permanent.

Types of Laser Etching Machines

There are two main types of laser etching machines: CO2 and fiber. CO2 machines use a gas laser to engrave and etch on materials such as wood, plastic, and glass. Fiber machines, on the other hand, use a solid-state laser to engrave and etch on metals and plastics. Both types of machines have their advantages and disadvantages.

Advantages of Laser Etching Machines

One of the primary advantages of laser etching machines is their precision. They can create incredibly detailed designs that would be impossible to achieve with traditional engraving methods. Additionally, laser etching machines are fast and efficient, allowing businesses to produce large quantities of products quickly. They are also incredibly versatile and can be used on a wide range of materials, including wood, metal, plastic, and glass.

Another advantage of laser etching machines is that they are environmentally friendly. Unlike traditional engraving methods that produce a lot of waste and use harsh chemicals, laser etching machines produce minimal waste and use a clean, safe laser beam to engrave and etch materials.

Disadvantages of Laser Etching Machines

One of the main disadvantages of laser etching machines is their cost. They can be quite expensive, especially for businesses that are just starting out. Additionally, laser etching machines require regular maintenance to keep them running smoothly, which can also be costly.

Another disadvantage of laser etching machines is that they have limitations when it comes to the size of the materials they can work with. While they are incredibly versatile, they may not be suitable for larger items such as furniture or vehicles.

Applications of Laser Etching Machines

Laser etching machines have a wide range of applications in various industries. In the manufacturing industry, they are commonly used for branding and labeling products. They can also be used for creating intricate designs on jewelry and other luxury items.

In the medical industry, laser etching machines are used for marking surgical tools and equipment. They are also used to engrave medical devices and implants, ensuring that they can be easily identified and traced back to their manufacturer.

In the automotive industry, laser etching machines are used to create designs on car parts and accessories. They can also be used for marking serial numbers and other identifying information on vehicles.

Also, read the Injection molding machine

Comments on “Laser etching machine – Parts, Working, Advantages”

Comments are closed.