Table of Contents

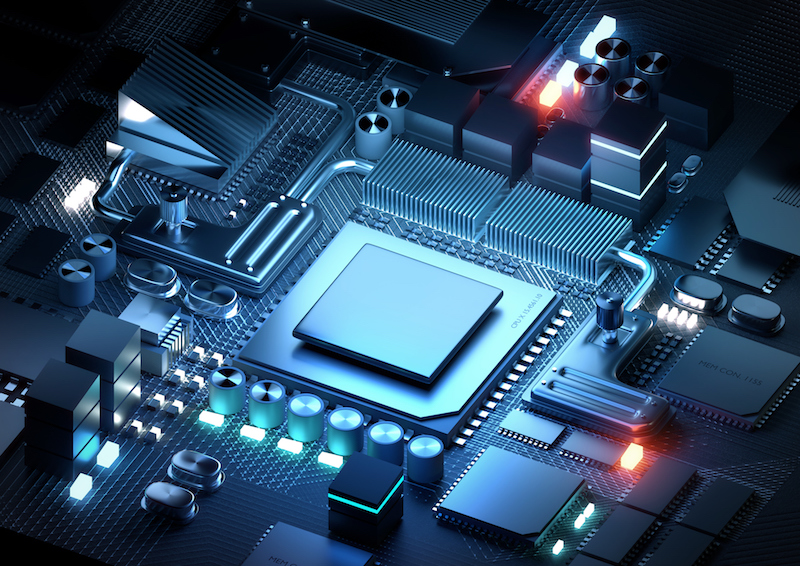

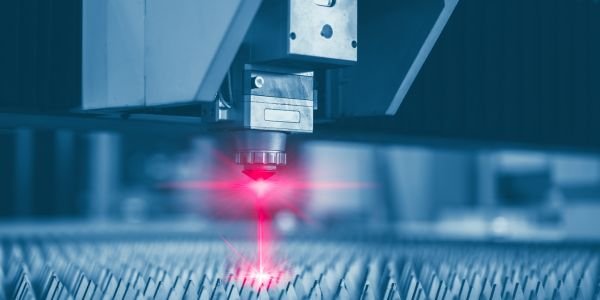

In modern manufacturing, precision, efficiency, and versatility are paramount. One technology that has revolutionized the industry in recent years is the fiber laser. Fiber lasers have rapidly gained popularity due to their exceptional capabilities, making them indispensable tools in various fields, including manufacturing, telecommunications, medical devices, and more.

Understanding the Basics of Fiber Lasers

How Do Fiber Lasers Work?

Fiber lasers are a type of solid-state laser, a category of lasers that rely on solid gain media rather than gases or liquids. The core component of a fiber laser is an optical fiber made of a rare-earth-doped glass or crystal. This fiber serves as the gain medium where light amplification occurs. The process begins with the injection of high-power diode laser light into the fiber core. This input energy excites the rare-earth ions in the core, causing them to emit photons.

These photons bounce back and forth within the core, continually stimulating the emission of more photons through a process known as optical amplification. The ends of the fiber are equipped with mirrors, creating an optical cavity, which allows the emitted photons to be reinforced further, resulting in a coherent and highly intense laser beam.

Advantages of Fiber Lasers

- High Beam Quality: Fiber lasers produce laser beams with exceptional beam quality, characterized by a well-defined and narrow focus. This high beam quality enables precision cutting, welding, and engraving in various materials.

- Efficiency: Fiber lasers are highly efficient, converting a significant portion of the input electrical power into laser light. This efficiency reduces power consumption and operating costs.

- Compactness: The compact design of fiber lasers makes them easy to integrate into manufacturing systems and provides flexibility in their deployment.

- Reliability: With no moving parts and a robust design, fiber lasers have a reputation for reliability and durability, resulting in reduced maintenance and downtime.

- Wavelength Versatility: Fiber lasers can be engineered to emit laser light at various wavelengths, allowing them to work with different materials and applications.

Applications of Fiber Lasers

The versatility of fiber lasers has led to their adoption in a wide range of applications across diverse industries. Here are some notable examples:

1. Material Processing

Fiber lasers are extensively used for cutting, welding, and marking various materials such as metals, plastics, ceramics, and composites. Their high precision and speed make them indispensable in industries like automotive manufacturing, aerospace, and electronics.

2. Medical Devices

In the medical field, fiber lasers are employed for delicate procedures like eye surgeries, dental treatments, and tissue ablation. Their precision and minimally invasive nature make them ideal for such applications.

3. Telecommunications

Fiber optic communication systems heavily rely on fiber lasers to transmit data over long distances. These lasers ensure the efficient and high-speed transmission of information through optical fibers.

4. Research and Development

Fiber lasers play a crucial role in scientific research, powering experiments in fields such as physics, chemistry, and materials science. Their reliability and versatility make them valuable tools for researchers.

5. Ablation and Micro-machining

Fiber lasers are used for precise ablation and micro-machining of materials, enabling the creation of intricate patterns and structures in semiconductors and microelectronics.

The Future of Fiber Lasers

As technology continues to advance, so too will the capabilities of fiber lasers. Future developments are expected to focus on improving beam quality, increasing power output, and expanding the range of wavelengths available. This will open up new possibilities for applications in fields like quantum technology, advanced materials processing, and defense.

In conclusion, fiber lasers have emerged as powerful tools with a wide array of applications across various industries. Their ability to deliver high precision, efficiency, and reliability has made them indispensable in modern manufacturing and beyond. As researchers and engineers continue to push the boundaries of what is possible, fiber lasers are set to play an even more prominent role in shaping the future of technology and innovation.

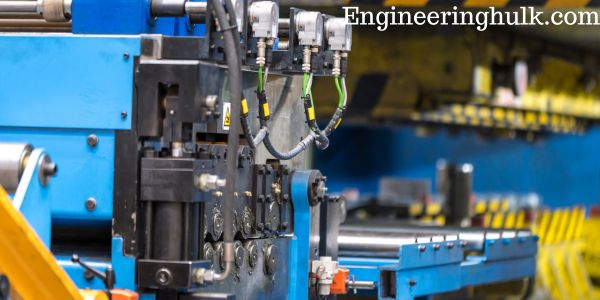

Construction of a Fiber Laser Cutting Machine

A fiber laser cutting machine consists of several key components:

1. Fiber Laser Source:

The core of the machine is the fiber laser source, which generates the high-intensity laser beam. Inside this source, a specially designed optical fiber, often doped with rare-earth elements like ytterbium or erbium, serves as the gain medium. The optical fiber is coiled to enhance light amplification through stimulated emission.

2. Beam Delivery System:

The generated laser beam then travels through a series of optical components responsible for shaping and focusing it. These components include:

- Collimation Lens: This lens helps transform the divergent beam emitted from the optical fiber into a parallel beam.

- Focusing Lens: After collimation, the beam is directed through a focusing lens that concentrates it into a small, intense spot known as the focus point. The precision of this focusing process is critical for achieving accurate cuts.

3. Cutting Head:

The focused laser beam is delivered to the cutting area through the cutting head. The cutting head is equipped with:

- Nozzle: This nozzle is responsible for the delivery of assist gases, such as oxygen or nitrogen, to the material being cut. The assist gas helps to blow away molten or vaporized material, preventing debris buildup and ensuring a clean cut.

- Capacitive Height Sensor: Some cutting heads include a capacitive height sensor, which maintains a constant distance between the nozzle and the material surface, ensuring optimal cutting performance.

4. Worktable:

The material to be cut is placed on a worktable. Depending on the machine’s design, the worktable may be fixed or moveable in various axes (X, Y, and Z) to facilitate precise positioning of the material.

5. CNC Controller:

The entire operation of the fiber laser cutting machine is computer-controlled. Computer-Aided Design (CAD) files are converted into Computer Numerical Control (CNC) instructions. These instructions guide the movement of the cutting head and regulate the laser’s intensity. The CNC controller ensures precise and repeatable cuts according to the design specifications.

Working on a Fiber Laser Cutting Machine

The operation of a fiber laser cutting machine involves several steps:

- Material Setup: The operator places the material to be cut on the worktable, ensuring it is securely positioned and aligned with the machine’s coordinate system.

- CAD File Import: The CAD design file of the desired cut is loaded into the machine’s CNC controller.

- Laser Activation: The fiber laser source is activated, and the laser beam is guided through the beam delivery system to the cutting head.

- Focusing and Cutting: The focused laser beam is directed onto the material’s surface. As the laser beam interacts with the material, it rapidly heats and vaporizes or melts the material, creating a narrow cut or kerf. The assist gas is simultaneously blown onto the cutting area to remove molten material and maintain cut quality.

- CNC Control: The CNC controller precisely guides the movement of the cutting head along the designated cutting path, following the CAD design. It also regulates the laser’s intensity to control the depth and speed of the cut.

- Completion: Once the cutting process is complete, the machine shuts down the laser source, and the finished part or cutout is removed from the worktable.

Fiber laser cutting machines excel in achieving high-precision cuts, making them ideal for industries such as metal fabrication, aerospace, and automotive manufacturing. Their efficiency, speed, and versatility have made them indispensable tools for modern manufacturing processes, enabling the creation of intricate designs and precise components across various materials.

Comment on “Fiber Laser: Illuminating Precision in Modern Manufacturing”

Comments are closed.