Table of Contents

What is a Vernier Caliper?

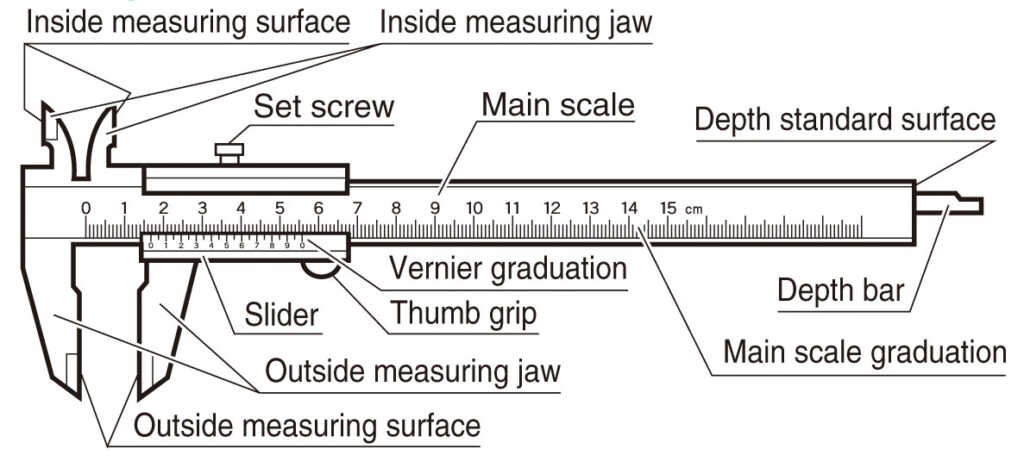

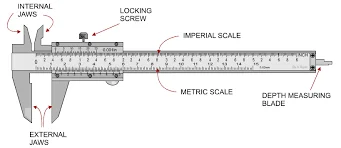

A Vernier caliper is a precision measuring tool used to measure an object’s dimensions accurately. It consists of two sets of jaws, one set of which slides along a scale while the other remains fixed.

The sliding jaw is connected to a vernier scale used to measure length, diameter, or depth accurately. The main body of the vernier caliper comprises two arms joined together by a pivot joint, allowing the vernier scale to move freely.

The two arms are graduated in metric units such as millimeters or centimeters. At the end of one arm is a small metal rod known as a vernier pointer. This pointer is used to measure the smallest increments of the measurement scale. The other arm of the vernier caliper is fitted with two jaws, the main jaw and the depth jaw.

The main jaw measures the outside diameter of an object, while the depth jaw measures the depth of a hole or groove. The vernier caliper is used in various applications, including engineering, machining, scientific research, and medical fields.

It is especially useful for measuring small objects as its accuracy and precision are unmatched by any other measuring tool. It is also very easy to use and can measure distances in the millimeters or centimeters range.

Overall, the vernier caliper is an invaluable measuring tool with high accuracy and precision when measuring objects. It is used extensively in many industries and must-have for any machinist or engineer.

The types of Vernier Calipers:

Vernier Calipers are precision measuring tools used to measure an object’s dimensions accurately. They are commonly used in engineering and manufacturing to measure various things, such as the outside and inside diameter of a cylinder, the depth of a hole, and the thickness of a sheet of material.

Several different types of Vernier Calipers are available on the market, each designed to measure different objects. The most common type of Vernier Caliper is the standard one. This type of caliper has two arms with a fixed jaw on one side and a movable jaw on the other.

The fixed jaw is used to measure the outside diameter, while the movable jaw is used to measure the inside diameter. This type of caliper is simple to operate and is the most commonly used. The depth caliper is similar to the standard caliper but has an additional arm to measure the depth of a hole or slot.

This type of caliper measures the depth of a hole in a cylinder, the depth of a recess, or the depth of a slot in a machine part. The disc caliper is designed to measure the diameter of a round object. It has two arms with a fixed jaw on one side and a movable jaw on the other.

The fixed jaw is used to measure the outside diameter, while the movable jaw is used to measure the inside diameter. This type of caliper is often used to measure the diameter of a round shaft or cylinder. The digital caliper is a more advanced type of caliper that is equipped with a digital display.

This caliper type measures various things, such as inside and outside diameters, depths, and angles. It is more accurate than the standard caliper and is often used in precision engineering or manufacturing.

Vernier calipers are invaluable tools for accurately measuring the dimensions of various objects in engineering and manufacturing. The different calipers are designed to measure different objects and are used in various applications.

Using a Vernier Caliper:

Using a Vernier caliper is a simple process that can be used to measure objects that range in size from small to large. It is often used in engineering, carpentry, and machining applications.

The Vernier caliper can measure objects’ length, depth, thickness, and diameter. It consists of two sets of jaws, one stationary and one moveable, that open and close on an object to take its measurements.

A Vernier scale is located on the caliper, which gives a precise reading of the measurements taken. To use a Vernier caliper, the object that is being measured should be placed between the jaws of the caliper.

The jaws should be wide enough to accommodate the object but not so vast that it allows it to move around. Once the object is in place, the moveable jaw can be moved towards the stationary jaw to close the caliper on the object.

At this point, the object should be held firmly in place so that the measurement is accurate. The Vernier scale on the caliper can then be used to take the precise reading of the measurement. The Vernier scale has two sets of lines, one which is the major scale and one which is the Vernier scale.

The Vernier scale is divided into smaller increments than the major scale and can be used to take a more precise reading. The exact measurement of the object can be taken by lining up the two sets of lines. Once the measurement has been taken, the Vernier caliper can be used to measure other objects.

The process is the same, but the measurements will differ depending on the object’s size. It is important to remember to always read the Vernier scale from left to right when taking measurements. Using a Vernier caliper is a simple and accurate way to measure the size and shape of objects.

It is often used in various engineering and machining applications and can be used to measure objects of varying sizes. With a bit of practice, anyone can quickly become proficient in using a Vernier caliper.

The Maintenance and Care of Vernier Calipers:

Vernier calipers are precision instruments that are used to take precise measurements of an object’s length, width, and diameter. Proper maintenance and care of your vernier calipers are essential to ensure accurate and reliable measurements.

First, it is important to always store your vernier calipers in a clean, dry, and dust-free environment. This will help prevent dirt or dust from entering the mechanism and causing inaccurate readings.

Additionally, it is essential to keep the calipers away from any chemicals or solvents, as these can corrode the metal components. Second, inspect the calipers regularly to ensure all the parts are in working order.

Ensure that all of the screws, bolts, and nuts are tightened correctly and that the jaws of the calipers are clean and free of any debris. Also, check the condition of the scale and needle, and make sure that the graduations are clear and legible.

Third, to maintain the accuracy of the calipers, it is essential to lubricate the moving parts. Use a lightweight oil or grease to lubricate the jaws, scale, and needle. This will help to ensure that the calipers are operating smoothly and accurately.

Comment on “Vernier caliper – Diagram, Definition, Types, Uses”

Comments are closed.