Table of Contents

Introduction

Cold welding, also referred to as contact welding, is a fascinating phenomenon and a solid-state welding technique that occurs when two clean, flat surfaces come into contact under high pressure in a vacuum or inert environment, fusing them without the need for heat or melting. Cold welding has been applied in a range of industries, from microelectronics to aerospace.

Definition:

Cold welding, also known as contact welding, is a solid-state welding process in which two metal surfaces are joined without the application of heat or the use of a filler material. This fusion occurs when clean, flat surfaces come into close contact under sufficient pressure, typically in a vacuum or inert environment.

The absence of an oxidizing atmosphere is crucial because most metals form an oxide layer when exposed to air, which can prevent direct metal-to-metal bonding. When two clean metal surfaces come into contact in such conditions, the atoms of one surface cannot differentiate between their own atoms and those of the adjacent surface, leading to atomic bond formation and resulting in a weld.

Cold welding has been known since ancient times. In antiquity, blacksmiths occasionally used it to join metals by hammering them together, an application of pressure without the need for the intense heat of a forge. However, it wasn’t until we ventured into space that the phenomenon took on new significance. In the vacuum of space, there are no oxidation layers to prevent metal surfaces from sticking together, making spacecraft vulnerable to accidental cold welding.

Parts of Cold Welding Machine:

- Frame or Housing: This is the main body of the machine, providing the structure that supports all other components.

- Die Holders: These are the components that hold the welding dies or wheels in place. Dies are crucial for the cold welding process, providing the necessary shape and pressure to the metals being welded.

- Dies or Wheels: These are replaceable components that come in direct contact with the metal pieces to be welded. They apply pressure to the metals and are usually made of a material harder than the metals being joined.

- Pressure Application Mechanism: This might include levers, hydraulic systems, or screw mechanisms that apply the necessary pressure for the weld.

- Alignment Mechanism: Ensures that the two pieces of metal are correctly aligned before and during the welding process.

- Metal Feed Mechanism: In continuous welding processes, like wire manufacturing, there is a mechanism to feed the metal into the welding area.

- Handle or Lever: Used to manually apply pressure or to operate the machine.

- Adjustment Knobs: These allow the operator to adjust various parameters, like the amount of pressure applied or the alignment of the metals.

- Cleaning or Surface Preparation Tools: Some cold welding machines might include tools or mechanisms to clean the metal surfaces before welding, ensuring that contaminants or oxides are removed.

- Base or Support: Provides stability to the machine during operation.

- Safety Features: These might include guards to protect the operator from moving parts, emergency stop buttons, or safety interlocks.

Mechanism of Cold Welding

- Surface Oxide Layer Disruption: Most metals, when exposed to air, develop an oxide layer on their surfaces. This layer can prevent the direct contact of metal atoms from each surface. When two metal surfaces are pressed together in a vacuum or inert atmosphere (where this oxide layer can be minimized or eliminated), cold welding can occur.

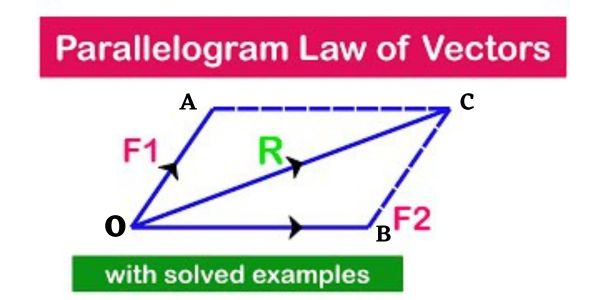

- Atomic Bond Formation: At a molecular level, when two clean metal surfaces come into contact, the atoms of one surface cannot distinguish between their own atoms and those of the other surface. This results in the diffusion of atoms across the interface, creating a bond.

- Importance of Clean Surfaces: The efficiency of cold welding significantly depends on the cleanliness of the surfaces. Impurities, contaminants, or oxide layers can hinder the process.

Factors Influencing Cold Welding

- Surface Cleanliness: As discussed, contaminants and oxides prevent cold welding. Thus, surfaces to be welded need to be cleaned at a microscopic level.

- Applied Pressure: Sufficient pressure ensures the close contact of metal atoms from each surface.

- Environment: An absence of an oxidizing environment, like a vacuum or inert atmosphere, promotes cold welding.

- Material Properties: Not all metals cold weld with the same efficiency. Ductile metals, like gold, copper, and silver, tend to cold weld more easily than brittle ones.

Applications of Cold Welding

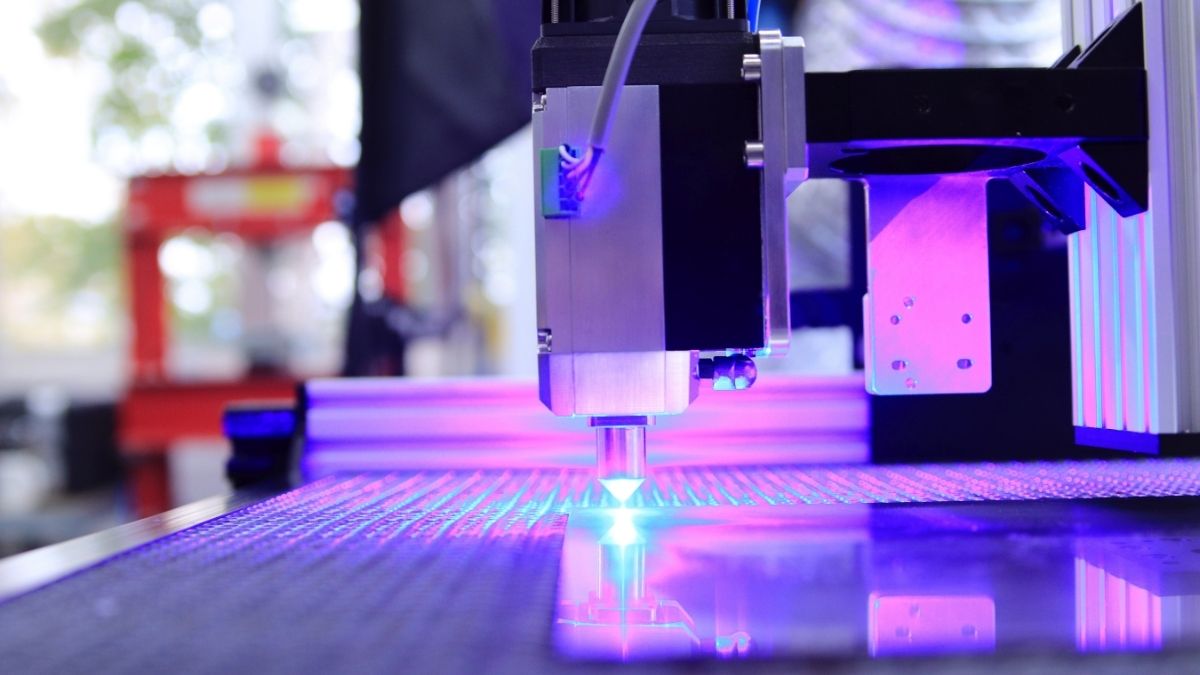

- Electronics Manufacturing: Cold welding is employed in the manufacture of wire bonds in microelectronic packages. Using ultrasonic energy, tiny gold or aluminum wires are cold welded to contact pads on semiconductor devices.

- Aerospace: While the risk of unintended cold welding in space is a concern, the principle is also utilized intentionally in spacecraft assembly where traditional welding might be problematic.

- Jewelry Making: Gold, being a highly ductile metal, can be cold welded. Some jewelers exploit this property to create seamless joints.

- Wire Butt Welding: In the wire industry, cold welding is used to join wires end-to-end without using filler material.

Advantages of Cold Welding

- Preservation of Material Properties: Since there’s no heat involved, the mechanical and chemical properties of metals remain unchanged post-welding.

- No Heat-Affected Zone: Traditional welding can create a heat-affected zone (HAZ) around the weld, which can be a weak point. Cold welding eliminates this risk.

- Clean and Eco-friendly: Without the need for fluxes or fillers, cold welding is a clean process. Additionally, it doesn’t produce harmful emissions or waste.

- Precision: Cold welding can achieve highly accurate and precise welds, especially useful in micro-scale applications.

Limitations and Challenges

- Preparation is Key: Cold welding requires immaculate surface preparation. Any contamination can hinder the welding process.

- Limited Material Selection: Not all metals are suitable for cold welding. Brittle metals and some alloys resist the process.

- Post-Weld Strength: While cold welding can achieve solid bonds, the joint’s strength can sometimes be less than that achieved by traditional welding methods.

Cold welding is a unique solid-state welding technique that has been known since ancient times but has gained increased significance with our ventures into space and the need for precision in microelectronics. While it has notable advantages, including the preservation of material properties and an eco-friendly process, it is not without its challenges.

The understanding and effective utilization of cold welding requires careful consideration of material selection, surface preparation, and the appropriate environment. As technology continues to advance and as industries push the boundaries of manufacturing and design, cold welding will likely continue to play an important role in joining materials where traditional methods fall short.

Also, read the ISO Standards