Table of Contents

Milling cutters are an essential tool for precision machining in a variety of industries. They are used to shape and cut different materials, including metal, wood, and plastic, and come in a wide range of shapes and sizes to meet different needs.

What is a Milling Cutter?

A milling cutter is a rotary cutting tool that is used to remove material from a workpiece. It typically has multiple cutting edges and can be mounted on a milling machine or a CNC machine to cut and shape a workpiece. Milling cutters are made from a variety of materials, including high-speed steel (HSS), carbide, and diamond.

Types of Milling Cutters

Milling cutters are classified based on their shape, size, and cutting edge. Here are the most common types of milling cutters:

End Milling Cutter

The end milling cutter is a type of milling cutter that is used for removing material from the end of a workpiece. It is a versatile tool that can be used for a variety of milling operations, such as profiling, slotting, and plunging. End milling cutters are available in different sizes, shapes, and materials. They are commonly made of high-speed steel, carbide, or cobalt.

Peripheral Milling Cutter

The peripheral milling cutter is also known as the slab milling cutter. It is a type of milling cutter that is used for cutting the outside edges of a workpiece. The peripheral milling cutter has teeth on the circumference of the cutter, and the cutting edges extend radially inward. It is a versatile tool that can be used for a variety of milling operations, such as slotting, side milling, and face milling.

Side Milling Cutter

A side milling cutter is a type of milling cutter used to cut materials perpendicular to the axis of rotation of the cutter. It has cutting teeth on the side of the cutter and can remove material quickly and efficiently. Side milling cutters are used in a wide range of applications, including slotting, facing, and contouring.

Staggered Milling Cutter

A staggered milling cutter is a type of milling cutter used to create a smooth surface finish on a workpiece. It has cutting teeth arranged in a staggered pattern, which reduces the amount of vibration during cutting and produces a smoother finish. Staggered milling cutters are commonly used in metalworking and are available in various sizes and materials.

Gang Milling Cutter

A gang milling cutter is a type of milling cutter used to cut multiple grooves or slots in a workpiece at once. It has multiple cutting teeth arranged in a row and can be used to cut materials quickly and efficiently. Gang milling cutters are commonly used in metalworking and are available in various sizes and materials.

T-Slot Milling Cutter

The T-slot milling cutter is a type of milling cutter that is used for milling T-slots in a workpiece. T-slots are commonly used for holding workpieces on milling machines. The T-slot milling cutter has a T-shaped slot on its cutting edge, which fits into the T-slot in the workpiece. This allows the milling cutter to cut the T-slot accurately.

Face Milling Cutter

The face milling cutter is a type of milling cutter that is used for milling flat surfaces on a workpiece. The face milling cutter has teeth on the face of the cutter, and the cutting edges extend radially inward. It is a versatile tool that can be used for a variety of milling operations, such as facing, profiling, and slotting.

Fly Milling Cutter

The fly milling cutter is a type of milling cutter that is used for milling slots in a workpiece. It has a cutting edge that is shaped like a fly’s wing, which allows the cutter to create slots that are wider than the cutter itself. The fly milling cutter is commonly used for cutting keyways and slots in gears.

Woodruff Cutter

The Woodruff cutter is a type of milling cutter that is used for milling keyways in a workpiece. It has a cylindrical shape with a flat bottom and a keyway on the cutting edge. The Woodruff cutter is commonly used for cutting keyways in shafts and gears.

Thread Milling Cutter

The thread milling cutter is a type of milling cutter that is used for milling threads in a workpiece. It has multiple cutting edges that allow it to create threads of various sizes and shapes. The thread milling cutter is commonly used for cutting threads in screws, bolts, and other threaded parts.

Hobbing Cutter

The hobbing cutter is a type of milling cutter that is used for milling gears in a workpiece. It has multiple cutting edges that allow it to create gear teeth of various sizes and shapes. The hobbing cutter is commonly used for cutting gears in automotive and industrial applications.

Dovetail Cutter

The dovetail cutter is a type of milling cutter that is used for milling dovetails in a workpiece. It has a cutting edge that is shaped like a dovetail, which allows it to create dovetail joints. The dovetail cutter is commonly used for cutting dovetails in woodworking and metalworking applications.

Ball Milling Cutter

The ball milling cutter is a type of milling cutter that is used for milling curved surfaces on a workpiece. It has a cutting edge that is shaped like a ball, which allows it to create curved surfaces with a smooth surface finish.

Concave Milling Cutter

A concave milling cutter is a type of milling cutter used to create a concave shape in a workpiece. It has a curved cutting edge and is used for shaping and contouring workpieces. Concave milling cutters are commonly used in metalworking and are available in various sizes and materials.

Cylindrical Milling Cutter

A cylindrical milling cutter is a type of milling cutter used to create cylindrical shapes in a workpiece. It has cutting teeth on the circumference of the cutter and can be used to cut materials quickly and efficiently. Cylindrical milling cutters are commonly used in metalworking and are available in various sizes and materials.

Hollow Milling Cutter

A hollow milling cutter is a type of milling cutter used to create hollow shapes in a workpiece. It has cutting teeth on the circumference of the cutter and can be used to cut materials quickly and efficiently. Hollow milling cutters are commonly used in metalworking and are available in various sizes and materials.

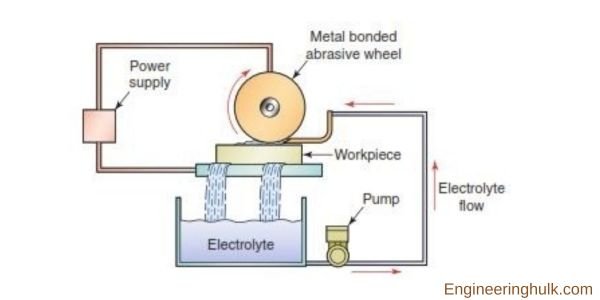

How do Milling Cutters Work?

Milling cutters work by removing material from a workpiece using their cutting edges. The workpiece is held in place by a vise or clamps, and the milling cutter is mounted on a spindle that rotates at high speed. As the cutter rotates, it engages with the workpiece and removes material from it. The depth and width of the cut are controlled by adjusting the height and position of the milling cutter.

Applications of Milling Cutters

Milling cutters are used in a wide range of applications, including:

1. Aerospace: Milling cutters are used to manufacture aircraft components, including engine parts and structural components.

2. Automotive: Milling cutters are used to manufacture automotive components, including engine blocks, transmission cases, and brake components.

3. Medical: Milling cutters are used to manufacture medical components, including implants and prosthetics.

4. Electronics: Milling cutters are used to manufacture electronic components, including printed circuit boards (PCBs) and computer parts.

5. Woodworking: Milling cutters are used to shape and cut wood for furniture, cabinetry, and other woodworking applications.

Also, read the theories of failure