Table of Contents

Introduction

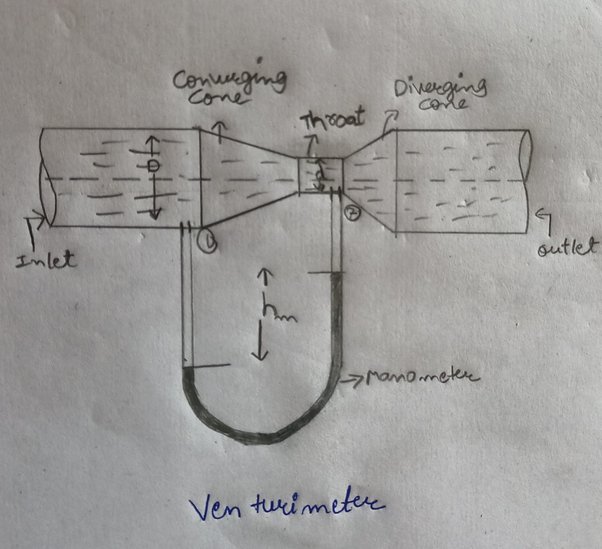

A venturi meter is a device used to measure the flow rate of a fluid in a pipe. It consists of a converging section, a throat section, and a diverging section. The fluid enters the converging section, where its velocity increases and its pressure decreases. The fluid then passes through the throat section, where the velocity reaches its maximum and the pressure reaches its minimum. Finally, the fluid passes through the diverging section, where its velocity decreases and its pressure increases.

Working Principle of Venturi meter

A venturi meter works on the principle of Bernoulli’s equation, which states that the total energy of a fluid flowing through a pipe is constant. This means that the sum of the kinetic energy, potential energy, and pressure energy of the fluid remains constant. As the fluid flows through the converging section of the venturi meter, its velocity increases and its pressure decreases.

This is because the converging section reduces the cross-sectional area of the pipe, causing the fluid to accelerate to maintain the same mass flow rate. According to Bernoulli’s equation, the increase in velocity results in a decrease in pressure.

In the throat section, the cross-sectional area of the pipe is the smallest, which causes the velocity to reach its maximum and the pressure to reach its minimum. The kinetic energy of the fluid is at its maximum in the throat section, and the pressure energy is at its minimum.

Finally, in the diverging section, the cross-sectional area of the pipe increases, causing the velocity to decrease and the pressure to increase. The pressure in the diverging section is higher than the pressure in the converging section but lower than the pressure in the throat section.

Bernoulli’s equation for a venturi meter

Bernoulli’s equation can be expressed mathematically as follows:

P1 + (1/2)ρV1^2 + ρgh1 = P2 + (1/2)ρV2^2 + ρgh2

Where:

– P1 and P2 are the pressures at the upstream and downstream sections of the venturi meter, respectively.

– V1 and V2 are the velocities of the fluid at the upstream and downstream sections of the venturi meter, respectively.

– ρ is the density of the fluid.

– g is the acceleration due to gravity.

– h1 and h2 are the elevations of the fluid at the upstream and downstream sections of the venturi meter, respectively.

To calculate the flow rate of the fluid, we need to solve for V2. Rearranging Bernoulli’s equation and assuming that the fluid is incompressible and has negligible viscosity, we get:

V2 = √((2*(P1 – P2))/ρ(1 – A2^2/A1^2))

Where:

– A1 and A2 are the cross-sectional areas of the pipe at the upstream and downstream sections of the venturi meter, respectively.

Using this equation, we can calculate the flow rate of the fluid in the pipe. The flow rate is given by:

Q = A2V2

Where Q is the flow rate and A2 is the cross-sectional area of the pipe at the throat section of the venturi meter.

Construction of Venturi meter

A venturi meter consists of three main parts: the converging section, the throat section, and the diverging section.

1. Converging Section:

The converging section is the inlet section of the venturi meter, where the fluid enters the device. It has a gradually decreasing diameter, which causes the fluid to increase its velocity while decreasing its pressure. The angle of the converging section is usually between 10 to 15 degrees.

2. Throat Section:

The throat section is the narrowest section of the venturi meter. It is a cylindrical section with a constant diameter that connects the converging and diverging sections. The pressure of the fluid at this point is the lowest, and its velocity is the highest.

3. Diverging Section:

The diverging section is the outlet section of the venturi meter, where the fluid exits the device. It has a gradually increasing diameter, which causes the fluid to decrease its velocity while increasing its pressure. The angle of the diverging section is usually between 5 to 7 degrees.

Materials Used in Venturimeter:

The construction of a venturi meter requires materials that are non-corrosive and can withstand high fluid pressure. The most commonly used materials are stainless steel, brass, and PVC.

Stainless Steel:

Stainless steel is a durable and corrosion-resistant material. It is suitable for measuring fluids with high temperatures and pressures. It is commonly used in venturi meters for measuring steam flow in power plants.

Brass:

Brass is a non-corrosive and easy-to-machine material. It is commonly used in venturi meters for measuring water flow in irrigation systems.

PVC:

PVC is a lightweight and inexpensive material. It is commonly used in venturi meters for measuring fluid flow in laboratories.

Installation of Venturi meter:

The installation of the venturi meter should be done carefully to ensure accurate measurements. The venturi meter should be installed in a straight section of the pipe, where the fluid flow is fully developed. The length of the straight section should be at least 10 times the diameter of the pipe upstream of the venturi meter and 5 times the diameter downstream of the venturi meter.

Where is the venturi meter used?

1. Water supply systems: Venturi meters are used to measure the flow rate of water in pipes.

2. Oil and gas industry: Venturi meters are used to measure the flow rate of oil and gas in pipelines.

3. Chemical industry: Venturi meters are used to measure the flow rate of chemicals in pipelines.

4. Power generation: Venturi meters are used to measure the flow rate of steam and other fluids in power plants.

Advantages of Venturi meter

1. Accurate measurement: Venturimeters provide accurate measurement of flow rate, as they are based on the principle of Bernoulli’s equation.

2. Low-pressure drop: Venturi meters have a lower pressure drop compared to other flow meters, which reduces energy consumption.

3. Low maintenance: Venturimeters have no moving parts, which means they require little maintenance.

4. Wide range of applications: Venturi meters can be used to measure the flow rate of different types of fluids, such as water, oil

Also, read types of welding

Comment on “Venturi meter – Working Principle, Construction,”

Comments are closed.