Table of Contents

Mechanical properties of materials refer to the physical characteristics of materials that describe their behavior under stress or strain. These properties are important for the design and selection of materials for various applications in engineering and other industries.

Definition of Mechanical Properties of Materials

Mechanical properties of materials are the physical properties that describe the response of materials to external forces or stresses. These properties include elasticity, plasticity, strength, toughness, hardness, ductility, and fatigue resistance, among others. These properties help engineers and designers to select the right materials for specific applications based on the expected stresses and loads.

Mechanical properties of materials

1. Strength: Strength is the ability of a material to withstand an applied load without breaking or deforming. The two most common types of strength are tensile strength and compressive strength. Tensile strength is the maximum stress a material can withstand before it breaks under tension, while compressive strength is the maximum stress a material can withstand before it breaks under compression. Engineers must consider both tensile and compressive strength when designing products to ensure that they can withstand the necessary loads without failing.

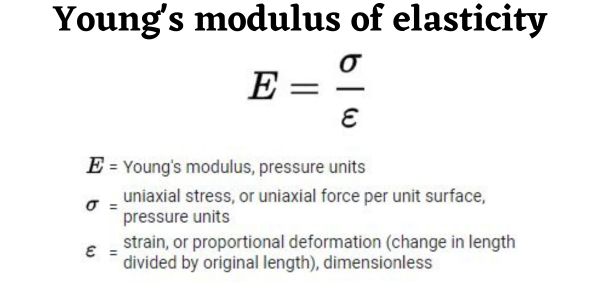

2. Elasticity: Elasticity is the ability of a material to return to its original shape after being deformed by an external force. A material that is highly elastic will return to its original shape quickly and completely when the force is removed, while a material that is less elastic will experience permanent deformation. Elasticity is important in applications where materials are subjected to repeated cycles of loading and unloading, such as in springs or shock absorbers.

3. Plasticity: Plasticity is the ability of a material to permanently deform without breaking under an applied load. A highly plastic material will be able to withstand large amounts of deformation without breaking, while a less plastic material will experience brittle failure. Plasticity is important in applications where materials are subjected to high levels of deformation, such as in metal-forming processes like forging or rolling.

4. Toughness: Toughness is the ability of a material to absorb energy without fracturing. A tough material will be able to absorb a significant amount of energy before breaking, while a less tough material will break with less energy input. Toughness is important in applications where materials are subjected to impact or sudden shock, such as in construction materials or machinery components.

5. Hardness: Hardness is the ability of a material to resist indentation or scratching. A hard material will be difficult to scratch or deform, while a less hard material will be more easily scratched or deformed. Hardness is important in applications where materials are subjected to wear or abrasion, such as in cutting tools or bearings.

6. Ductility: Ductility is the ability of a material to deform plastically without breaking when subjected to tensile stress. A highly ductile material will be able to withstand significant deformation without breaking, while a less ductile material will experience a brittle fracture. Ductility is important in applications where materials are subjected to stretching or bending, such as in metal forming or wire drawing.

7. Brittleness: Brittleness is the tendency of a material to fracture or break without significant deformation when subjected to stress. A highly brittle material will fracture with little deformation, while a less brittle material will experience significant deformation before fracturing. Brittleness is important in applications where materials are subjected to sudden or unexpected stresses, such as in safety-critical components.

8. Fatigue resistance: Fatigue resistance is the ability of a material to resist failure under cyclic loading. This property is characterized by the material’s fatigue limit, which is the maximum cyclic stress that the material can withstand without failure.

Types of Mechanical Properties of Materials

Mechanical properties of materials can be classified into two broad categories:

1. Elastic properties: Elastic properties describe how a material behaves under elastic deformation, which means that the material can recover its original shape when the applied stress is removed. Elastic properties include:

a) Young’s modulus of elasticity: Young’s modulus is the measure of a material’s stiffness. It is the ratio of stress to strain within the proportional limit of the material.

b) Poisson’s ratio: Poisson’s ratio describes the ratio of lateral strain to longitudinal strain in a material when subjected to an axial force.

c) Shear modulus: Shear modulus is the measure of a material’s resistance to shear deformation.

2. Plastic properties: Plastic properties describe how a material behaves under plastic deformation, which means that the material undergoes permanent deformation when the applied stress exceeds the material’s yield strength. Plastic properties include:

a) Yield strength: Yield strength is the amount of stress a material can withstand without undergoing plastic deformation.

b) Ultimate tensile strength: Ultimate tensile strength is the maximum stress a material can withstand before breaking.

c) Ductility: Ductility is the measure of a material’s ability to deform under tensile stress without breaking.

Examples of Mechanical Properties of Materials

Different materials exhibit different mechanical properties, which determine their suitability for different applications. Here are some examples of the mechanical properties of common materials:

1. Steel: Steel is a strong, stiff, and tough material that exhibits high yield strength and ultimate tensile strength. It is commonly used in construction, transportation, and manufacturing.

2. Aluminum: Aluminum is a lightweight material that exhibits high ductility, toughness, and fatigue resistance. It is commonly used in the aerospace, automotive, and packaging industries.

3. Copper: Copper is a soft, ductile, and malleable material that exhibits high electrical and thermal conductivity. It is commonly used in electrical wiring, plumbing, and electronics.

4. Titanium: Titanium is a strong, lightweight, and corrosion-resistant material

Also, read the shear modulus

Comments on “Mechanical Properties of Materials”

Comments are closed.