Table of Contents

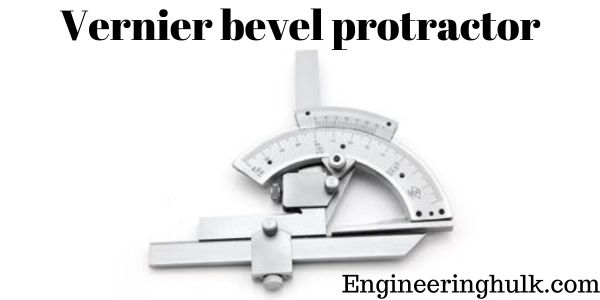

A Vernier bevel protractor is a measuring tool that is used to measure angles with great accuracy. It is a versatile tool that is used in various industries, including engineering, manufacturing, and construction.

What is a Vernier bevel protractor?

A Vernier bevel protractor is a precision tool that is used to measure angles accurately. It consists of a base, a swivel arm, a Vernier scale, and a bevel protractor. The base is the flat surface that is used to support the protractor, and the swivel arm is the part that rotates around the base.

The Vernier scale is a graduated scale that is used to measure the angle, and the bevel protractor is the part that is used to measure the angle.

How does a Vernier bevel protractor work?

To use a Vernier bevel protractor, you first need to place the base on a flat surface. Then, you need to rotate the swivel arm until it is at the desired angle. The Vernier scale is then used to measure the angle. The Vernier scale is a graduated scale that is used to measure small angles with great accuracy. It consists of a fixed scale and a movable scale.

The fixed scale is the main scale, and it is divided into equal parts. The movable scale is the Vernier scale, and it is divided into a different number of parts than the fixed scale. The movable scale is used to measure the angle between the two arms of the bevel protractor.

A Vernier bevel protractor is a precision measuring instrument that is used to measure angles with a high degree of accuracy. It consists of a base, a blade, and a Vernier scale. The Vernier scale provides a more precise measurement than a regular scale, and the bevel protractor is used for measuring angles that are not easily accessible with other tools.

What is the accuracy of a Vernier bevel protractor?

The accuracy of a Vernier bevel protractor is an essential factor to consider when using this measuring instrument.

The accuracy of a Vernier bevel protractor refers to the degree of closeness of the measured angle to its true value. The accuracy of a Vernier bevel protractor is typically measured in terms of its least count. The least count is the smallest measurement that can be made with the Vernier scale.

The least count of a Vernier bevel protractor is usually 5 or 10 arc seconds, which means that it can measure angles with a precision of 5 or 10 arc seconds. This level of precision is quite high and makes the Vernier bevel protractor an ideal instrument for measuring angles in precision engineering and machining.

Factors that affect the accuracy of a Vernier bevel protractor

Several factors can affect the accuracy of a Vernier bevel protractor. These factors include:

1. Temperature: Temperature can affect the accuracy of a Vernier bevel protractor. When the temperature changes, the dimensions of the instrument can change, causing errors in the measurements. It is essential to keep the Vernier bevel protractor at a constant temperature during use.

2. Operator error: The accuracy of a Vernier bevel protractor can be affected by the operator’s error. If the operator does not read the Vernier scale correctly, it can lead to errors in the measurement. It is important to ensure that the operator is properly trained in using the instrument.

3. Wear and tear: The accuracy of a Vernier bevel protractor can be affected by wear and tear. If the instrument is not properly maintained, it can lead to errors in the measurement. It is important to regularly inspect and maintain the instrument to ensure its accuracy.

4. Calibration: Calibration is critical to ensure the accuracy of a Vernier bevel protractor. It is important to calibrate the instrument regularly to ensure that it is measuring angles accurately.

Applications of Vernier bevel protractor

Vernier bevel protractors are used in various industries, including engineering, manufacturing, and construction. They are used to measure angles with great accuracy, which is essential in these industries. Some of the applications of Vernier bevel protractors include:

1. Machining operations: Vernier bevel protractors are used in machining operations to ensure that the correct angle is maintained. They are used in milling, drilling, and grinding operations.

2. Welding: Vernier bevel protractors are used in welding operations to ensure that the correct angle is maintained. They are used to measure the angle of the joint and to ensure that the welding is done at the correct angle.

3. Carpentry: Vernier bevel protractors are used in carpentry to ensure that the correct angle is maintained. They are used to measure the angle of the joints and to ensure that the joints are cut at the correct angle.

4. Construction: Vernier bevel protractors are used in construction to ensure that the correct angle is maintained. They are used to measure the angle of the joints and to ensure that the joints are cut at the correct angle.

Also, read the principal stress

Comment on “Vernier bevel protractor – Working, Accuracy & Applications”

Comments are closed.