Table of Contents

We’re surrounded by breakthrough materials, experimental composites, and futuristic alloys that promise to reshape modern engineering and design. And yet titanium holds its ground. In fact, it’s gaining ground. From aerospace to architecture, this decades-old material remains a first-choice staple simply because it’s dependable.

The “why” behind this is remarkably simple: titanium is incredibly durable, exceptionally corrosion-resistant, and lighter than steel with similar strength. It’s the kind of material that doesn’t need reinvention; it just requires proper application.

Titanium vs. Time

Here’s a number that speaks volumes: titanium alloys retain more than 95% of their strength after 20 years of exposure in marine environments—without significant corrosion. The reason this matters so much is that while a lot of materials can handle short-term stress, only a few can endure long-term exposure to salt, heat, pressure, and time itself.

Titanium does it effortlessly, and this is why the metal is a cornerstone in applications like offshore drilling, desalination plants, and naval systems—where other materials either rust, crack, or quietly fail. Its oxide layer acts as a self-healing skin, constantly resisting degradation.

From Titanium Grades to Global Impact

Different industries lean on different grades of titanium, each tailored to specific performance needs. Grade 2 is a go-to choice for chemical processing due to its corrosion resistance, while Grade 5 (Ti-6Al-4V) is the star of the aerospace industry for its exceptional strength-to-weight ratio. And then there’s Grade 23, used in medical implants where both biocompatibility and fatigue resistance are critical.

When asking what is titanium used for, the answer spans jet engines, spinal implants, race cars, architectural facades, and even the bolts holding satellites together. In other words, titanium is already shaping the future of infrastructure, healthcare, and mobility. But its real power lies in precision, because when the grade fits the challenge, titanium redefines what performance means.

The Engineering Sweet Spot

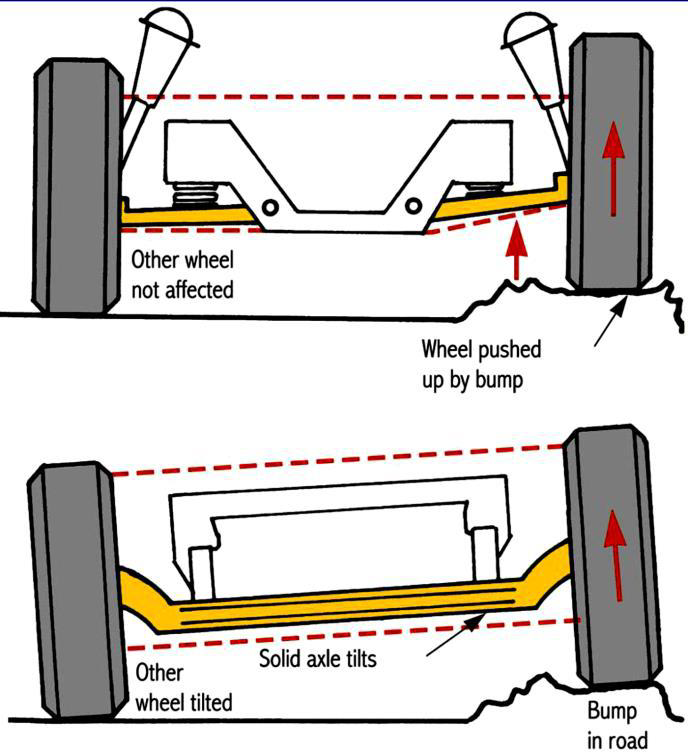

Titanium delivers a rare double play: it’s about 45% lighter than steel, yet nearly as strong. That alone would be enough to catch the eye of every aerospace and automotive engineer trying to shed weight without sacrificing performance. But the real value appears in practice: lighter aircraft mean better fuel efficiency, which translates to lower emissions and operating costs. In EVs, reduced weight extends battery life and driving range.

In architecture, lighter materials can reduce structural loads and even foundation costs. But unlike lighter alternatives like aluminum, titanium resists corrosion and endures stress cycles without fatigue. This combination of lightness and longevity is what makes it a favorite among engineers who need to deliver performance without compromise.

A Future-Built Metal in a Present-Minded World

We often confuse “new” with “better,” but longevity tells a different story. Construction projects aren’t meant to go viral—they’re meant to endure. From climate extremes to constant mechanical stress, today’s infrastructure is under more pressure than ever before. Titanium’s fatigue resistance and thermal stability make it a long-game player in a short-attention-span world. Unlike newer composite materials, which may still be undergoing real-world validation, titanium brings decades of proven performance.

And as sustainability becomes a requirement, not just a buzzword, materials with longer life cycles and lower maintenance costs offer measurable environmental benefits. Titanium may not be flashy—but in a landscape of planned obsolescence, that’s exactly what makes it powerful. We don’t just need stronger materials. We need smarter ones, and titanium turns out, is both.

Also, read about Engineering Materials