Table of Contents

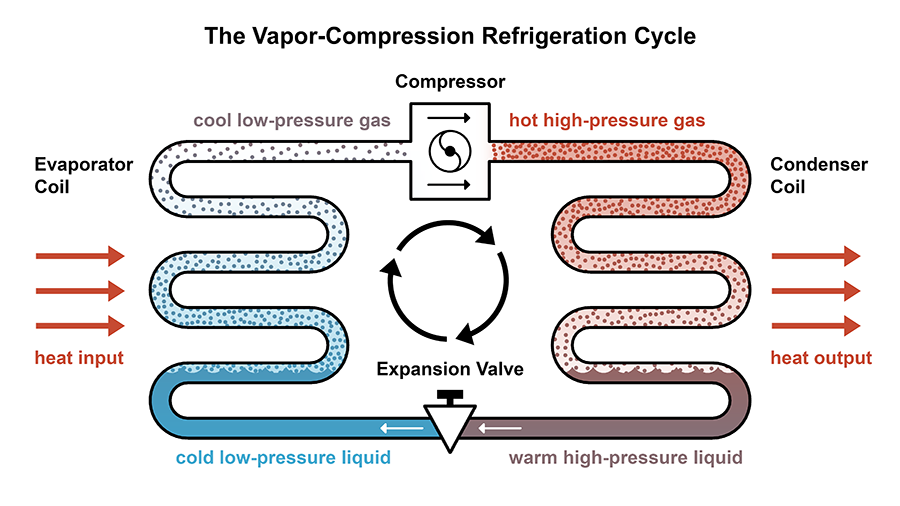

Refrigerant leaks are a significant concern in the heating, ventilation, and air conditioning (HVAC) industry. Not only can they impact system efficiency and operation, but they can also harm the environment and pose health risks. Fortunately, refrigerant leak detectors provide an effective way to locate and address these leaks.

Importance of Refrigerant Leak Detection:

- Environmental Concerns: Many refrigerants, especially older types like CFCs and HCFCs, have been identified as ozone-depleting substances. Even newer, more environmentally friendly refrigerants can contribute to global warming if released.

- System Efficiency: A leaky HVAC system operates inefficiently. Even a small leak can cause the system to work harder, increasing energy consumption and costs.

- Costs: Refrigerants are expensive. Leaks lead to refrigerant loss, which requires costly replenishment.

- Safety: Some refrigerants can be flammable or harmful if inhaled in large quantities. Detecting and fixing leaks can prevent potential hazards.

Types of Refrigerant Leak Detectors:

- Electronic or Ultrasonic Detectors: These use sensors to detect the presence of refrigerants. When the sensors come into contact with the refrigerant, an alarm or signal is activated. They can detect even minute concentrations, making them highly effective.

- Ultraviolet (UV) Dye Detectors: A UV dye is added to the refrigerant. If there’s a leak, the dye will escape with the refrigerant. When illuminated with a UV light, the dye will glow, indicating the leak’s location.

- Soap Bubble Method: This is a simple method where a soap solution is applied to suspected leak points. If there’s a leak, the escaping refrigerant will produce bubbles. While it’s not as sophisticated as other methods, it’s inexpensive and can be effective for larger leaks.

- Infrared Leak Detectors: These detectors use infrared technology to detect the specific wavelengths that refrigerants emit. They can be very accurate and are less prone to false alarms than some other types.

Best Practices for Using a Refrigerant Leak Detector:

- Calibration: Regular calibration ensures that your detector operates at peak efficiency.

- Routine Checks: Even if there aren’t apparent signs of a leak, conducting regular checks can preempt potential problems.

- Follow Manufacturer Guidelines: Always refer to the user manual for guidance on operation, maintenance, and calibration.

- Battery Life: Ensure your detector’s battery is fully charged or replaced regularly. A low battery can give inaccurate results.

- Environment Considerations: Some detectors might give false readings in windy conditions or when there are other chemicals present. Be aware of environmental conditions that might impact the detector’s accuracy.

- Safety First: Always wear appropriate protective equipment, like gloves and safety glasses, when working with refrigerants.

Refrigerant leak detectors are an invaluable tool for HVAC professionals. They not only ensure the efficient operation of systems but also play a critical role in environmental conservation and safety. Whether you’re a seasoned technician or a homeowner looking to maintain your HVAC system, understanding the importance and functionality of these detectors is essential.

By employing the best practices mentioned above, you can ensure that your HVAC system remains leak-free and operates efficiently for years to come.

Also, read the hardness test