Table of Contents

What is Metal Hamming?

Metal hemming is a vital process in the field of sheet metal fabrication and manufacturing. It involves bending, folding, or curling the edge of a metal sheet to create a secure, finished, and aesthetically pleasing joint. Whether you’re a professional in the manufacturing industry or a DIY enthusiast, understanding the techniques, applications, and benefits of metal hemming can be invaluable.

Techniques of Metal Hemming

- Overlapping Hemming: Overlapping hemming is one of the most common techniques employed in sheet metal fabrication. In this method, the edge of one metal sheet is folded over the edge of another sheet, creating a tight and secure joint. This technique is particularly useful in automotive manufacturing, where it ensures the strength and durability of vehicle components.

- Edge Hemming: Edge hemming involves bending the edge of a metal sheet, typically at a 90-degree angle, to create a smooth and safe edge. This is often seen in applications such as the edges of doors, hoods, and panels, where safety and aesthetics are crucial.

- Curl Hemming: Curl hemming, also known as roll hemming, is a technique where the edge of the metal sheet is rolled or curved. It is commonly used in manufacturing household appliances and electronics, where rounded edges improve both the appearance and safety of the product.

- Flush Hemming: Flush hemming is a technique that involves folding one edge of the metal sheet to sit flush with the adjacent surface. This technique is widely used in the aerospace industry, as it creates aerodynamic and sleek designs that reduce drag and improve fuel efficiency.

Applications of Metal Hemming

- Automotive Industry: Metal hemming plays a crucial role in the automotive industry, where it is used to join various body panels and components. This technique ensures the structural integrity of vehicles and enhances their safety.

- Aerospace Industry: In the aerospace sector, metal hemming is used to create smooth and streamlined surfaces on aircraft, reducing air resistance and improving fuel efficiency. It is also essential for sealing joints in aerospace components to maintain airtightness.

- Electronics and Appliances: Many consumer electronics and household appliances utilize metal hemming to create sleek and attractive designs. The technique not only enhances the appearance of these products but also ensures the safety of users by eliminating sharp edges.

- Construction: Metal hemming is employed in architectural and construction applications to join metal panels and create weatherproof and aesthetically pleasing facades. It is particularly valuable for cladding systems that require precise alignment and durability.

Benefits of Metal Hemming

- Enhanced Aesthetics: Metal hemming creates clean, finished edges that improve the visual appeal of products and structures. This aesthetic enhancement is especially important in industries where appearance matters, such as automotive and consumer electronics.

- Improved Safety: By eliminating sharp edges and ensuring secure joints, metal hemming enhances the safety of products and reduces the risk of injuries during handling and use.

- Structural Integrity: Metal hemming provides structural reinforcement to metal components, making them more robust and durable. This is crucial in industries like automotive and aerospace, where safety and reliability are paramount.

- Weather Resistance: In construction and architectural applications, metal hemming helps create weather-resistant seals and joints, preventing moisture and environmental elements from infiltrating structures.

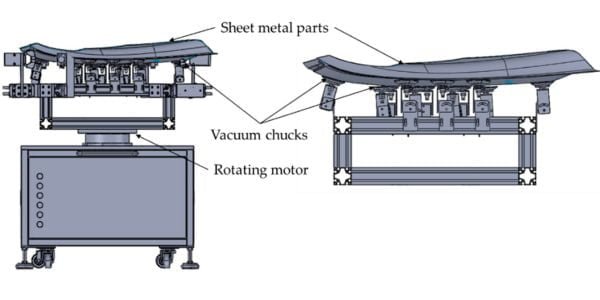

Metal Hemming Machine

A metal hemming machine is a specialized piece of equipment used in sheet metal fabrication and manufacturing processes. It is designed to fold, bend, or curl the edges of metal sheets, creating secure, finished, and aesthetically pleasing joints. These machines are available in various sizes and configurations, catering to the specific needs of different industries and applications.

How Does a Metal Hemming Machine Work?

The operation of a metal hemming machine involves several key components and steps:

- Feeding Mechanism: Metal sheets are loaded into the machine using a feeding mechanism. The sheets are typically fed in a sequential manner to ensure precision in the hemming process.

- Clamping System: The machine has a clamping system that holds the metal sheet securely in place during the hemming process. This ensures that the sheet remains in the correct position for accurate folding or bending.

- Hemming Tooling: Hemming tooling consists of dies, punches, and other components that are responsible for shaping and folding the edges of the metal sheet. These toolings can be customized to achieve different hemming profiles, such as overlapping, edge, curl, or flush hemming.

- CNC Control: Many modern metal hemming machines are equipped with computer numerical control (CNC) systems that allow for precise programming of hemming patterns and parameters. This ensures repeatability and accuracy in production.

- Hemming Process: The machine activates the hemming tooling, which then bends or folds the metal sheet’s edge according to the programmed specifications. The precise control and force are applied to ensure a consistent and secure hemmed joint.

Applications of Metal Hemming Machines

- Automotive Industry: Metal hemming machines are extensively used in the automotive sector for joining various body panels, hoods, doors, and trunk lids. They help create strong and visually appealing seams that contribute to the overall aesthetics and safety of vehicles.

- Aerospace Industry: In aerospace manufacturing, metal hemming machines are crucial for producing aerodynamic and streamlined components. These machines enable the fabrication of aircraft panels and parts with minimal drag and enhanced fuel efficiency.

- Electronics and Appliance Manufacturing: Metal hemming is employed to achieve sleek and safe designs in consumer electronics and household appliances, such as smartphones, laptops, and kitchen appliances.

- Construction and Architecture: Hemming machines are used in architectural and construction applications to create weather-resistant and visually appealing facades, roofing, and cladding systems.

Advantages of Metal Hemming Machines

- Precision: Metal hemming machines offer high levels of precision and repeatability, ensuring consistent and accurate results in sheet metal fabrication.

- Efficiency: These machines significantly reduce the time and labor required for hemming processes, leading to improved production efficiency.

- Versatility: Metal hemming machines can accommodate a wide range of sheet metal sizes and materials, making them adaptable to various applications and industries.

- Safety: By automating the hemming process, these machines reduce the risk of workplace injuries associated with manual hemming techniques.

Metal hemming is a versatile and essential technique in various industries, from automotive manufacturing to construction and electronics. Its ability to enhance aesthetics, improve safety, and ensure structural integrity makes it a valuable process in sheet metal fabrication.

Whether you are a professional in the field or a DIY enthusiast, understanding the techniques, applications, and benefits of metal hemming can help you achieve better results in your projects.

Also, read Brazing