Table of Contents

Introduction

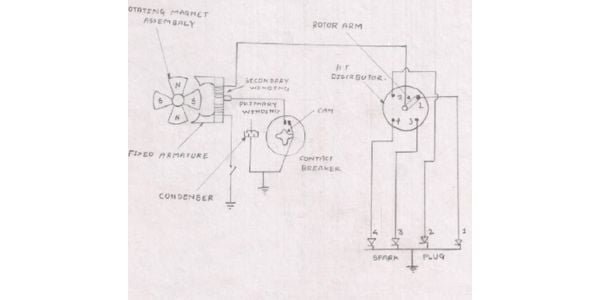

The ignition system is a crucial component of internal combustion engines, responsible for initiating the combustion process that powers vehicles and machinery. Among the various types of ignition systems, the magneto ignition system has gained prominence due to its reliability and self-sufficiency.

Understanding the Magneto Ignition System

The magneto ignition system is an autonomous electrical system used in internal combustion engines to generate the high-voltage sparks necessary to ignite the air-fuel mixture in the engine’s combustion chamber. Unlike battery-powered systems, the magneto ignition system generates its own electricity, eliminating the need for an external power source. This feature makes it highly dependable and suitable for a wide range of applications, including automobiles, motorcycles, small engines, and aircraft.

Components of a Magneto Ignition System

1. Magnet:

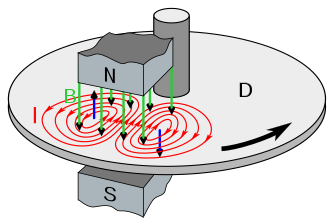

The fundamental component of a magneto ignition system is a permanent magnet, typically made of neodymium or alnico. This magnet is mounted on the engine’s flywheel and rotates as the engine runs. Its rotation generates a magnetic field that serves as the foundation for the system’s operation.

2. Ignition Coil:

The ignition coil plays a pivotal role in transforming the low-voltage electrical current produced by the magneto into high-voltage sparks capable of igniting the fuel-air mixture. It consists of primary and secondary windings, designed to amplify the voltage from the magneto.

3. Breaker Points:

The breaker points, also known as contact points, are a pair of metal contacts that open and close to control the flow of electric current within the magneto ignition system. The opening and closing of these points are precisely timed to trigger the spark generation process.

4. Condenser:

The condenser, or capacitor, works in conjunction with the breaker points. It acts as a temporary storage unit for electrical energy, reducing arcing at the points and ensuring a smooth and efficient spark generation process.

Functioning of a Magneto Ignition System

1. Magnetic Field Generation:

As the engine’s flywheel rotates, the magnet attached to it generates a rotating magnetic field. This movement induces an electrical current within the ignition coil.

2. Current Amplification:

The primary winding of the ignition coil receives the low-voltage, high-amperage current induced by the magnetic field. This current builds up a magnetic energy field.

3. Breaker Point Operation:

Synchronized with the engine’s rotation, the breaker points open and close at specific intervals. When the points are closed, the current flows through the primary winding, increasing the magnetic energy field.

4. Spark Generation:

As the breaker points open, the sudden interruption of the current flow causes the magnetic energy field to collapse rapidly. This rapid change in the magnetic field induces a high-voltage current in the secondary winding of the ignition coil.

5. Voltage Amplification:

The secondary winding of the ignition coil has significantly more turns than the primary winding, resulting in voltage amplification. This amplified voltage is crucial for generating a strong spark.

6. Spark Ignition:

The high-voltage current travels from the ignition coil to the spark plug through the high-tension lead. As the current encounters the spark plug’s electrode gap, it ionizes the air-fuel mixture, creating a spark that ignites the mixture and initiates the combustion process.

Advantages of a Magneto Ignition System

1. Self-Sufficiency:

The self-generating nature of the magneto ignition system eliminates the need for an external power source, ensuring reliable ignition even in situations where the battery or electrical system malfunctions.

2. Reliability:

Magneto ignition systems are renowned for their durability and ability to withstand harsh operating conditions. They are not susceptible to voltage fluctuations or battery failures, making them a dependable choice for various applications.

3. Instantaneous Sparks:

The design of magneto ignition systems allows for the instantaneous generation of high-voltage sparks. This instantaneous spark initiation leads to reliable ignition, improved engine performance, and efficient fuel combustion.

4. Minimal Maintenance:

Magneto ignition systems require minimal maintenance. Periodic inspection and cleaning of the breaker points, along with regular replacement of spark plugs, are typically sufficient to ensure their optimal functioning.

Types of Magneto Ignition Systems

1. Low-Tension Magneto Ignition System

The low-tension magneto ignition system is one of the earliest forms of magneto ignition. In this system, the primary winding of the ignition coil is part of the magneto armature. It generates a low-voltage current, typically ranging from 6 to 25 volts, which is sent directly to the spark plugs without any external coil. The low-tension magneto ignition system is commonly found in vintage engines, early automobiles, and stationary engines.

Advantages:

– Simplicity in design and operation.

– No need for an external ignition coil.

– Suitable for low-voltage applications.

Disadvantages:

– Limited voltage output, leading to weaker sparks.

– Less efficient in high-compression engines.

2. High-Tension Magneto Ignition System

The high-tension magneto ignition system is widely used in modern vehicles and machinery. It incorporates an external ignition coil in addition to the magneto. The primary winding of the ignition coil is connected to the magneto, while the secondary winding is responsible for generating high-voltage sparks. This system operates at higher voltages, typically in the range of 20,000 to 30,000 volts.

Advantages:

– Higher voltage output, resulting in stronger and more reliable sparks.

– Suitable for high-compression engines.

– Improved engine performance and fuel efficiency.

Disadvantages:

– Requires an external ignition coil, adding complexity to the system.

3. Capacitor Discharge Ignition (CDI) System

The Capacitor Discharge Ignition (CDI) system is a variation of the magneto ignition system that utilizes electronic components for enhanced performance. In this system, the magneto generates low-voltage AC (Alternating Current), which is rectified and stored in a capacitor. When the spark plug needs to be fired, the stored energy is rapidly discharged into the ignition coil, creating a high-voltage spark.

Advantages:

– Higher energy storage capacity, leading to stronger sparks.

– Improved spark timing and ignition control.

– Suitable for high-performance engines, motorcycles, and racing applications.

Disadvantages:

– Increased complexity due to electronic components.

– Requires a power source, usually a battery, for the electronic circuitry.

4. Solid-State Ignition (SSI) System

The Solid-State Ignition (SSI) system is a modern variant of the magneto ignition system that replaces the traditional breaker points with solid-state electronic components. This eliminates the need for mechanical contact points, resulting in improved reliability, reduced maintenance, and more precise spark timing. The SSI system is commonly found in small engines, lawnmowers, and other outdoor power equipment.

Advantages:

– Eliminates mechanical contact points, reducing wear and maintenance.

– Enhanced spark timing accuracy.

– Improved durability and reliability.

Disadvantages:

– Requires a power source, typically a battery, to operate the electronic components.

– Limited to smaller engines and applications.

The applications of a magneto ignition system

1. Tractors, Oil Burners, and Outboard Motors

2. Trucks and Cement Mixers

3. Buses

4. Airplane Engines

5. Power Units, Marine Engines, and Natural Gas Engines

Also, read Babcock and Wilcox boiler

Comment on “Magneto Ignition System: Function, Components, & Advantages”

Comments are closed.