Table of Contents

Technical considerations

Biogas Generation Plant: The biogas plant consists of two components: a digester (or fermentation tank) and a gas reservoir. The digester is a cubic or cylindrical-shaped impermeable container with a mouth into which the fermentable mixture is introduced in the form of a slurry.

The gas reservoir is normally an airtight steel reservoir that, floating like a ball in the fermentation mixture, interrupts the air in the digester (anaerobiosis) and collects the generated gas. In one of the popular designs, the gas reservoir is equipped with a gas outlet, while the digester is equipped with a drainpipe to convey the sludge to a drainage shaft.

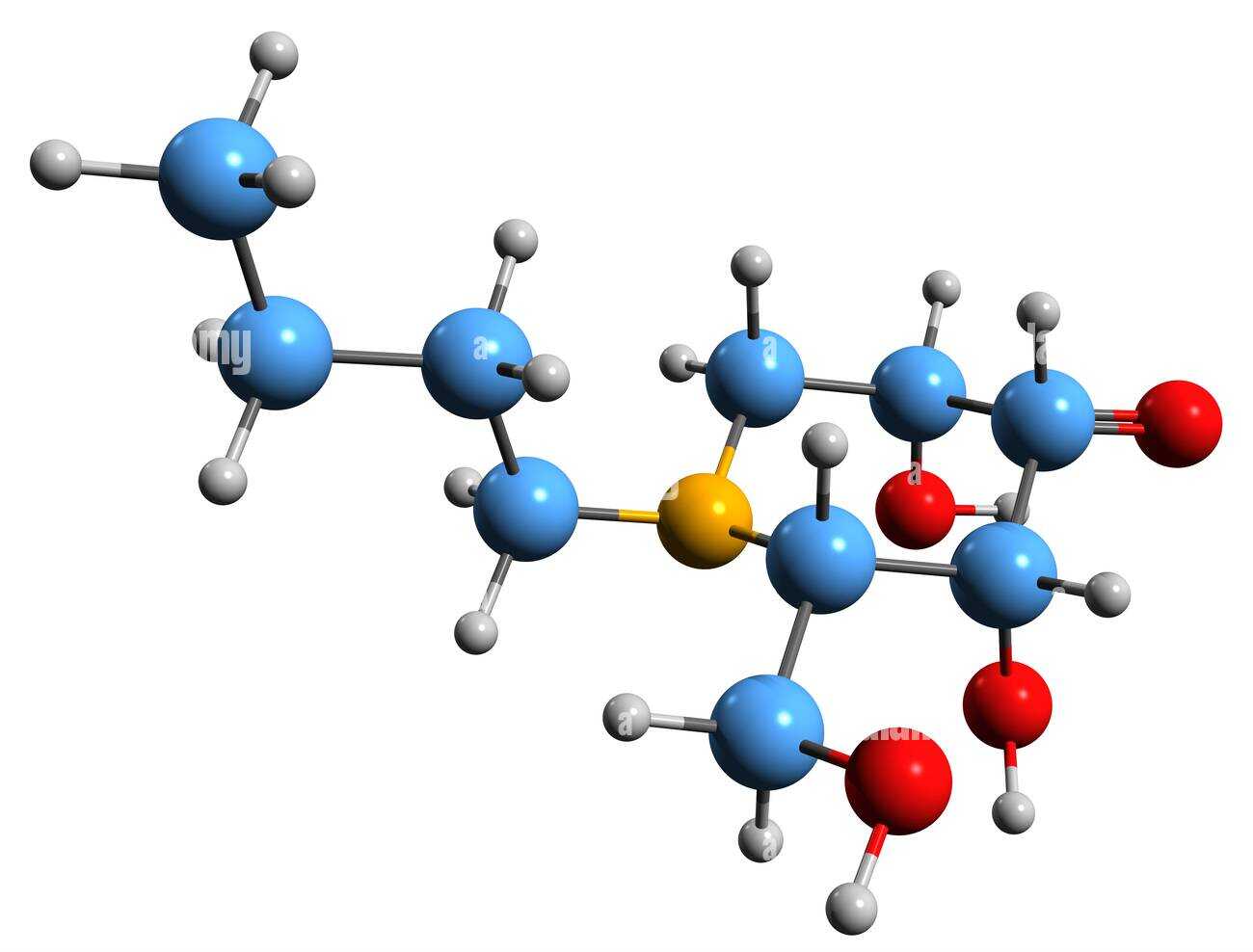

Scheme of the Gobar-Gas plant used to obtain methane from manure by anaerobic fermentation.

The constructional details of biogas generation plants, design, and economics of biogas plants have been addressed in the literature. For the constructional details of the biogas generation plant, the important criteria are:

- The amount of gas required for one or more specific uses and

- The amount of waste material available for processing.

Literature Review:

Singh has documented several guidelines to consider when designing compartmentalized and non-compartmentalized batch (periodic feed) and continuous (daily feed) constructional details of biogas generation plants that are vertical or horizontal. In addition, Loll has recently dealt with scientific principles, the engineering of processes and forms of digestion reactors, and the economics of technology.

Digestive reactors are built in brick, concrete, concrete, and steel. In Indonesia, where rural skills in brickmaking, bricklaying, plastering, and bamboo crafts are well established, clay bricks have successfully replaced concrete and cinder blocks. In areas where the cost is high, the “sausage” or bag digester seems to be ideal. The digester is constructed of 0.55mm width Hypalon laminated with neoprene and reinforced with nylon constructional details of a biogas generation plant.

The bag is equipped with a PVC inlet and outlet. Although imported from the United States, the cost of the digester and gas tank (both combined in one bag) is only 10% of that of a steel-cement digester. Another advantage is that it can be mass-produced and easily shipped. In rural areas, the entire installation is completed in minutes. A hole in the floor accommodates the bag, which is filled with two-thirds of the wastewater. The gas production completely inflates the bag, which is weighed and equipped with a compressor to increase the gas pressure.

Environmental and operational considerations

Raw materials

In constructional details of biogas generation plant waste materials can be obtained from a variety of sources: livestock and poultry waste, nocturnal soil, crop residues, food processing, and paper waste and materials such as aquatic weeds, water hyacinth, filamentous algae, and algae. Different problems are encountered with each of these wastes regarding the collection, transportation, treatment, storage, utilization of the waste, and end-use.

Agricultural sector waste such as straw, hay, sugar cane straw, corn stubble, vegetable stubble, and bagasse must be crushed to facilitate its flow to the digester reactor and to increase the efficiency of bacterial action. Succulent plant material produces more gas than dry matter and therefore materials such as shrubs and weeds require semi-drying.

The storage of the raw material in a humid and confined environment for more than ten days starts the anaerobic bacterial action which, while causing a certain loss of gas, reduces the time needed to start up the digester.

Influent solids content

Constructional details of biogas generation plant production are inefficient if the fermentation materials are too diluted or too concentrated, resulting in low biogas production and insufficient fermentation activity respectively. Experience has shown that the ratio of raw material (household and poultry waste and manure) to water should be 1: 1, i.e., 100 kg of excrement per 100 kg of water. In the slurry, this corresponds to a total solid concentration of 8-11 percent by weight.

Loading

The size of the digester depends on the load, which is determined by the content of the influencing solids, the retention time, and the temperature of the digester. Optimal loading speeds vary according to the different digesters and their locations. Faster charging speeds have been used when the ambient temperature is high. In practice, the loading rate should be an expression of the weight of total volatile solids (TVS) added per day per unit volume of the digester. This last principle is normally used for the correct functioning of the digester of constructional details of a biogas generation plant.

Sowing

Common practice involves sowing with an adequate population of acid-forming and methanol-forming bacteria. Active digestion of sludge from a wastewater treatment plant is the ideal “seed” material. As a general guideline, the seed material should be twice the volume of fresh manure slurry during the initial stage, with a gradual decrease in the amount added over three weeks.

PH

A low pH inhibits the growth of methanogenic bacteria and the generation of gas and is often the result of overload. A successful pH range for anaerobic digestion is 6.0 – 8.0; efficient digestion occurs at a pH close to neutral. A slightly alkaline state indicates that the pH fluctuations are not too drastic. Low pH can be resolved by diluting or adding lime.

Temperature

With a mesophilic flora, digestion occurs at best between 30 and 40 ° C; with thermophiles, the ideal range is 50 – 60 C. The choice of temperature to use is influenced by climatic considerations. In general, there is no rule, but for optimal process stability, the temperature must be carefully regulated within a narrow range of operating temperatures.

As a safety measure, it is common practice to bury digesters, due to the advantageous insulating properties of the soil, or to use a cover for greenhouses. Heating requirements, and therefore costs, can be minimized by using natural materials such as leaves, sawdust, straw, etc., which are composted in batches in a separate compartment around the digester.

Nutrients

Maintaining optimal microbiological activity in the digester is essential for gas generation and, consequently, is related to nutrient availability. Two of the most important nutrients are carbon and nitrogen and a critical factor when choosing raw materials is the overall C / N ratio.

Domestic wastewater and animal and bird waste are examples of nitrogen-rich materials that provide nutrients for the growth and multiplication of anaerobic organisms. N-poor materials such as green grass, corn stubble, etc., on the other hand, are rich in carbohydrates essential for gas production. Excessive nitrogen availability leads to the formation of NH3, whose concentration inhibits further growth.

Ammonia toxicity can be resolved with a reduced charge or by dilution. In practice, it is important to maintain a C/N ratio close to 30:1 by weight to obtain an optimal digestion speed. The C / N ratio can be wisely manipulated by combining low-carbon materials with high-nitrogen materials and vice versa.

Toxic materials

Constructional details of biogas generation plant Potential toxicity due to ammonia can be corrected by correcting the C/N ratio of the manure by adding bagasse or chopped straw, or by dilution. Common toxic substances are soluble salts of copper, zinc, nickel, mercury, and chromium. On the other hand, sodium, potassium, calcium, and magnesium salts can have a stimulating or toxic action, both being associated with the cation and not with the anionic portion of the salt. Pesticides and synthetic cleaners can also be irritating to the process.

Agitation

When there are solid materials in the digester that are not crushed well, gas generation can be hampered by the formation of a foam composed of these low-density solids that are trapped in a filamentous matrix. Over time, the foam hardens, interrupting the digestion process and causing stratification.

Agitation, normally necessary for bath digesters, guarantees the exposure of new surfaces to bacterial action, avoids viscous stratification delays bacterial activity, and favors the uniform dispersion of influencing materials in the fermentation liquor, also accelerating digestion in the constructional details of biogas generation plant.

Bottlenecks, considerations, and research and development Bioconversion of household and agricultural organic waste has become interesting because its technology has been successfully tested through experience in small and large-scale projects.

Feeding on renewable and non-polluting resources in process technology, the constructional details of the biogas generation plant have a triple function: waste removal, environmental management, and energy production. However, there are still several problems that prevent the efficient operation of biogas generation systems.

Also, read about Nose Types

FAQ

What are the key components of a biogas generation plant?

A biogas generation plant typically consists of several essential components, including an anaerobic digester, feedstock storage system, feeding system, mixing and agitation system, gas collection system, gas storage system, gas purification system, and gas utilization system.

What is the purpose of the anaerobic digester in a biogas plant?

The anaerobic digester is the core component of a biogas generation plant. Its primary purpose is to facilitate the anaerobic digestion process, where organic materials are broken down by bacteria in the absence of oxygen, resulting in the production of biogas. The digester provides an environment for the bacteria to thrive and efficiently convert the organic matter into biogas.

How does the feeding system work in a biogas plant?

The feeding system in a biogas plant is responsible for delivering the organic feedstock into the anaerobic digester. The feedstock, which can include a variety of organic materials such as agricultural waste, food waste, and animal manure, is loaded into the digester through a controlled feeding mechanism. The system ensures a consistent supply of feedstock to maintain optimal digester performance.

What is the purpose of the gas collection system in a biogas plant?

The gas collection system in a biogas plant is designed to capture the produced biogas from the anaerobic digester. It consists of a network of pipes or channels that collect the gas released during the digestion process. The collected biogas is then transported to the gas storage system for further processing and utilization.

How is biogas stored in a biogas generation plant?

Biogas is typically stored in a gas storage system, which can include gas holders or gas storage tanks. Gas holders are flexible structures that expand or contract based on the volume of gas produced, while gas storage tanks are rigid containers. Both systems provide a means to store biogas until it is needed for utilization.

What is the purpose of the gas purification system in a biogas plant?

The gas purification system in a biogas plant is responsible for removing impurities and contaminants from the biogas to improve its quality. Common purification techniques include scrubbing, filtration, and chemical treatments. The purified biogas is then ready for utilization in various applications.

How is biogas utilized in a biogas generation plant?

Biogas can be utilized in multiple ways in a biogas generation plant. It can be used for electricity generation by burning it in a biogas engine or turbine, which drives a generator. The heat generated during this process can also be captured and used for heating applications. Additionally, biogas can be upgraded to biomethane and injected into the natural gas grid or used as a vehicle fuel.

What safety measures are important in the construction of a biogas plant?

Safety is crucial when constructing a biogas plant. It is essential to incorporate proper ventilation systems to prevent the buildup of potentially dangerous gases. Safety features like gas leakage detectors, emergency shutdown systems, and explosion-proof electrical equipment should be installed. Adequate training and adherence to safety protocols are also critical for plant operators.

What are some environmental benefits of biogas generation plants?

Biogas generation plants offer several environmental benefits. They help reduce greenhouse gas emissions by capturing and utilizing methane, a potent greenhouse gas produced during the decomposition of organic matter. By using organic waste as feedstock, they also contribute to waste management and reduce the need for landfilling.

Additionally, biogas plants promote sustainable agriculture by providing a renewable energy source and nutrient-rich digestate as a byproduct.Are there any specific design considerations for biogas generation plants in different climates?

Yes, the design of biogas generation plants can be influenced by the climate in which they are located. In colder climates, for example, insulation and heating systems may be necessary to maintain optimal digestion temperatures. In hotter climates, cooling systems or temperature control mechanisms may be required to prevent overheating. Site-specific factors, such as rainfall patterns and potential flooding, also need to be considered during the design and construction phases.

Comments on “Constructional Detail of Biogas Generation Plant in 2024”