Table of Contents

Introduction:

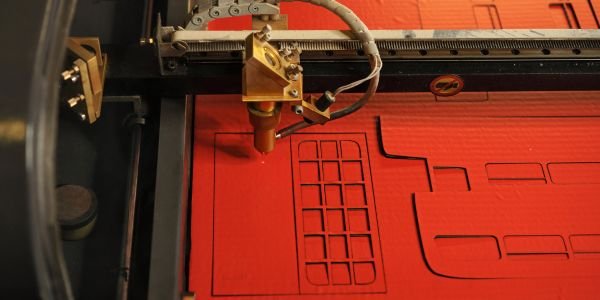

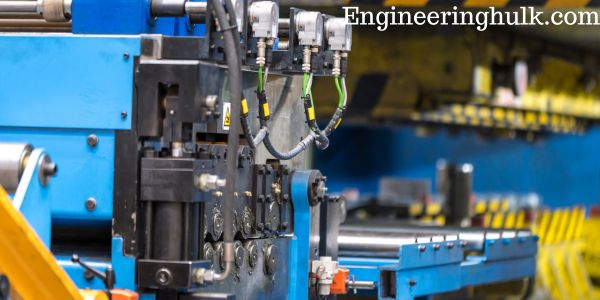

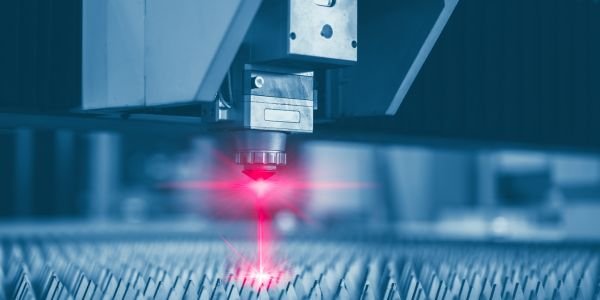

Laser engraving is a cutting-edge technology used to create intricate and precise designs on a wide range of materials. A laser engraver is a machine that uses a high-powered laser to etch and cut various materials with incredible accuracy.

What is a Laser Engraver?

A laser engraver is a machine that uses a laser beam to engrave or cut various materials such as metal, plastic, wood, and glass. The machine directs a high-powered laser beam at the material, which vaporizes or melts the material to create the desired design.

Laser engravers are often used to create custom designs on a variety of objects such as jewelry, trophies, and promotional items. They are also used in industrial settings to engrave part numbers, barcodes, and serial numbers onto products.

Parts of a Laser Engraver

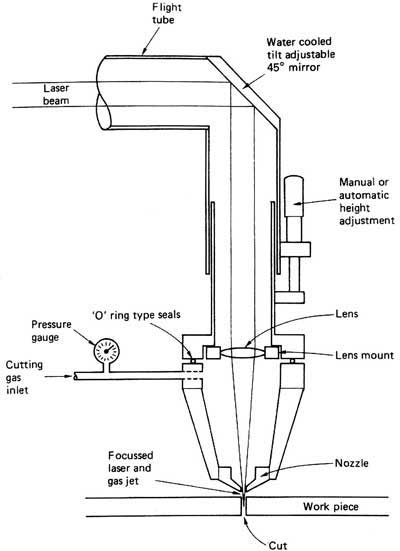

The main parts of the Laser Engraving machine include:

1. Laser Tube

The laser tube is the heart of a laser engraver. It generates the laser beam that is used to engrave or cut the material. The laser tube is typically made of glass and filled with a gas such as carbon dioxide or nitrogen. When electricity is applied to the gas, it produces a high-powered laser beam.

2. Laser Head

The laser head is the part of the machine that holds the laser tube and directs the laser beam onto the material. It typically consists of a focusing lens that concentrates the laser beam onto the material, a mirror that reflects the laser beam, and a motor that moves the laser head across the material.

3. Control Panel

The control panel is the interface between the user and the laser engraver. It allows the user to input the design to be engraved, adjust the settings such as the speed and power of the laser, and control the movement of the laser head.

4. Work Bed

The working bed is the surface on which the material to be engraved or cut is placed. It is typically made of a material such as acrylic or aluminum and may be adjusted to different heights to accommodate different thicknesses of materials.

Working as a Laser Engraver

The laser engraving process involves several steps that work together to create precise designs on various materials. These steps include:

1. Design Input

The first step in the laser engraving process is to input the design to be engraved into the control panel. This can be done using software such as CorelDraw or Adobe Illustrator.

2. Material Preparation

The next step is to prepare the material to be engraved. This may involve cleaning the surface of the material, applying a mask to protect certain areas from the laser beam, or clamping the material onto the work bed.

3. Laser Settings

Once the material is prepared, the laser settings such as the power and speed of the laser beam are adjusted on the control panel. These settings depend on the type of material being engraved and the desired depth of the engraving.

4. Laser Engraving

With the laser settings adjusted and the material prepared, the laser engraving process can begin. The laser head moves across the material, directing the laser beam onto the surface to create the desired design. The laser beam vaporizes or melts the material to create the design.

5. Finishing

Once the laser engraving is complete, the material may need to be cleaned or polished to remove any debris or residue left behind by the laser engraving process.

Advantages of a Laser Engraver Machine

1. Precision

One of the biggest advantages of laser engraving machines is their precision. They are capable of etching or engraving even the most intricate designs onto a wide variety of materials, including wood, plastic, metal, and glass.

2. Versatility

Another advantage of laser engraving machines is their versatility. They can be used to engrave on a variety of materials, as well as for a wide range of applications, including personalized gifts, industrial marking, product branding, and more.

3. Efficiency

Laser engraving machines are also very efficient, as they can complete the engraving process quickly and with great accuracy. This makes them an excellent choice for businesses looking to streamline their production processes.

4. Customization

Laser engraving machines also offer a high level of customization, allowing users to create unique designs for a wide range of applications. This makes them ideal for businesses looking to offer personalized products or for individuals looking to create custom gifts.

Disadvantages of a Laser Engraver Machine

1. Cost

One of the biggest disadvantages of laser engraving machines is their cost. They can be quite expensive, which may make them prohibitive for some individuals or businesses.

2. Maintenance

Laser engraving machines also require regular maintenance to keep them in good working order. This may involve cleaning the laser lens, replacing worn-out parts, and more, which can add to the overall cost of ownership.

3. Safety

Another potential disadvantage of laser engraving machines is the safety risk associated with working with a high-powered laser. It is important to follow all safety guidelines and protocols to prevent injury.

Applications of a Laser Engraver Machine

1. Personalized Gifts

One of the most popular applications for laser engraving machines is the creation of personalized gifts. They can be used to etch or engrave names, dates, and other personalized information onto a variety of materials, making them ideal for weddings, anniversaries, and other special occasions.

2. Industrial Marking

Laser engraving machines are also used for industrial marking, where they can be used to create permanent marks on a wide variety of materials, including metal, plastic, and glass. This makes them ideal for product branding and identification.

3. Artistic Engraving

Laser engraving machines can also be used for artistic engraving, where they can be used to create intricate designs on a wide range of materials, including wood, glass, and leather. This makes them popular among artists and designers.

4. Medical Applications

Laser engraving machines are also used in the medical field, where they can be used to etch or engrave surgical instruments, medical devices, and more. This makes them ideal for ensuring that medical equipment is properly identified and traceable.

Also, read the Plasma cutter

Comment on “Laser Engraver – How it Works? Learn in detail”

Comments are closed.