Table of Contents

Introduction

Gears are a vital component in the mechanical world. They play an important role in the transfer of power and motion between two shafts. Gears are used in various machines ranging from simple hand tools to complicated spacecraft. There are different types of gear available, each with a unique design and function.

Types of Gears

Spur Gears

Spur gears are the most commonly used type of gear. They have straight teeth that are parallel to the axis of rotation. Spur gears are used to transfer motion between two parallel shafts. They are easy to manufacture and have a high-efficiency rate.

Helical Gears

Helical gears have teeth that are angled along the gear’s surface. This angle allows for smoother engagement between gears, which results in less noise and vibration. Helical gears are used to transfer motion between two parallel shafts.

Bevel Gears

Bevel gears are used to transfer motion between two perpendicular shafts. They have conical teeth that mesh together. Bevel gears are commonly used in automobiles, machine tools, and printing presses.

Worm Gears

Worm gears are used to transfer motion between perpendicular shafts. They consist of a worm gear and a worm wheel. The worm gear has a spiral tooth that meshes with the worm wheel’s teeth. Worm gears are used in heavy-duty applications, such as construction equipment and industrial machinery.

Rack and Pinion Gears

Rack and pinion gears are used to convert rotational motion into linear motion. The pinion gear rotates, and the rack gear moves in a straight line. Rack and pinion gears are commonly used in steering systems in automobiles and other vehicles.

Planetary Gears

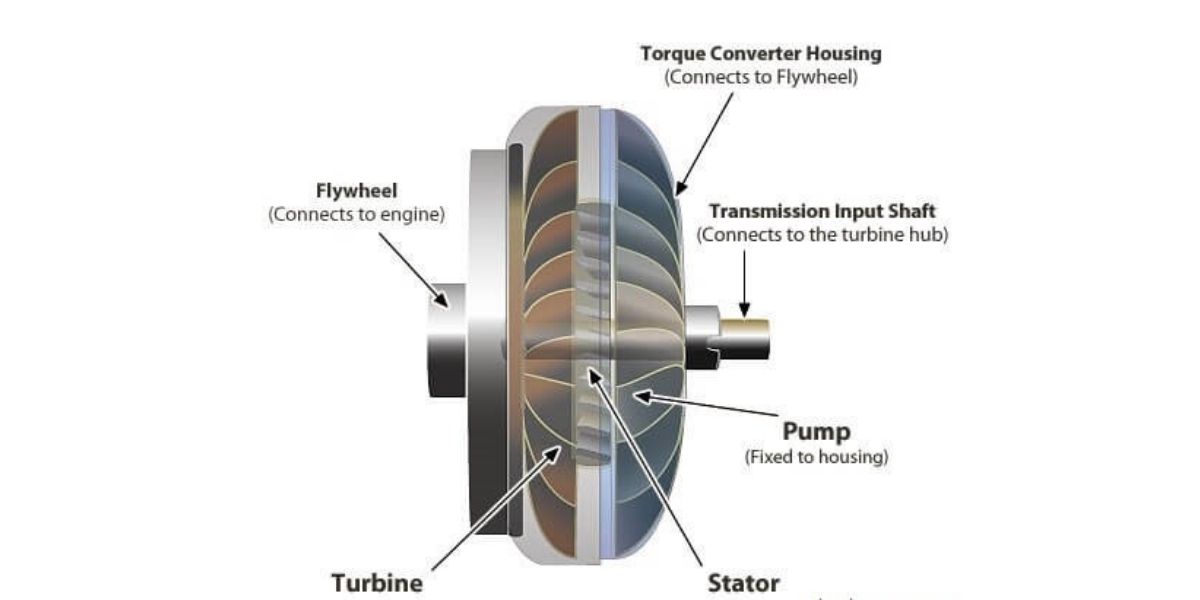

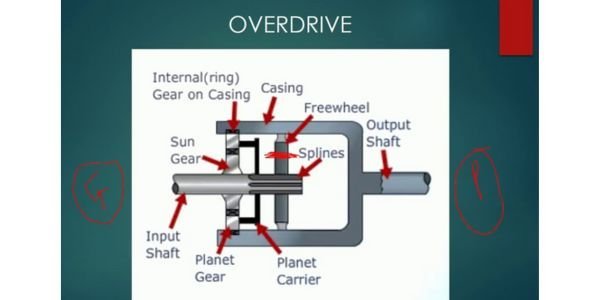

Planetary gears consist of central sun gear, planet gears, and ring gear. The planet gears rotate around the sun gear, and the ring gear meshes with the planet gears. Planetary gears are used in automatic transmissions and other complex machinery.

Hypoid Gears

Hypoid gears are similar to bevel gears, but their teeth are offset from the gear’s centerline. This allows for more torque to be transferred between two perpendicular shafts. Hypoid gears are commonly used in rear axles in automobiles.

Cycloidal Gears

Cycloidal gears consist of a circle with a series of pins that mesh with a gear. The gear has a series of lobes that mesh with the pins. Cycloidal gears are used in printing presses and other machinery that requires precise motion control.

Applications of Gears

Automotive Industry

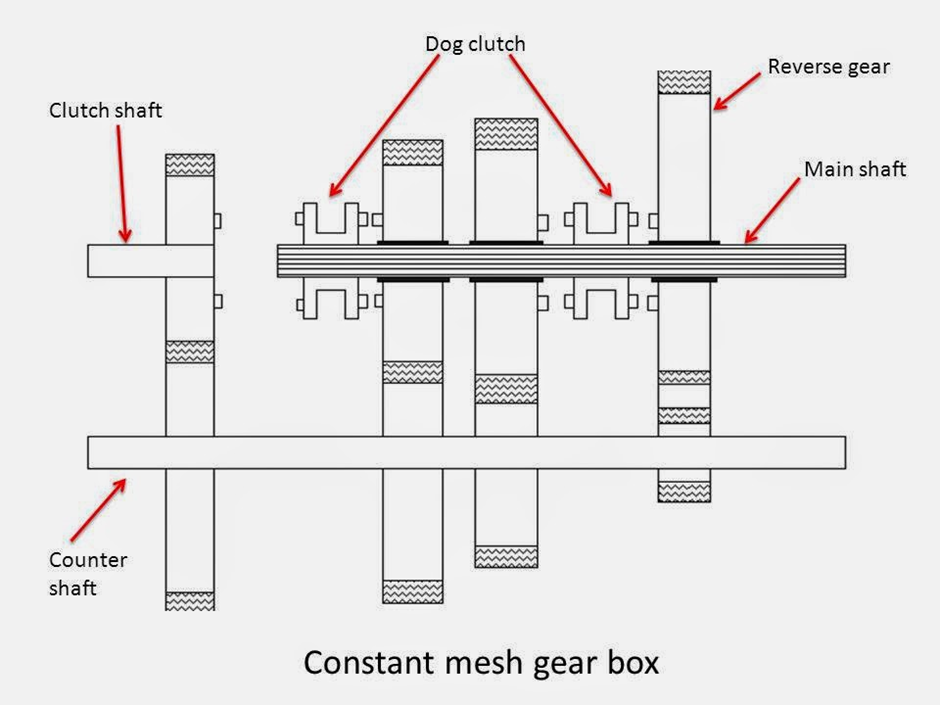

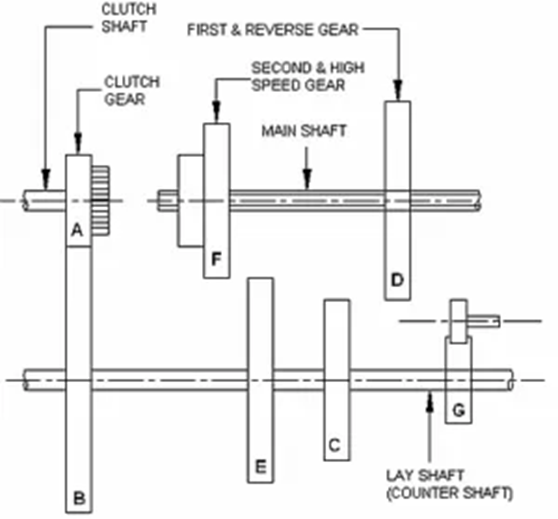

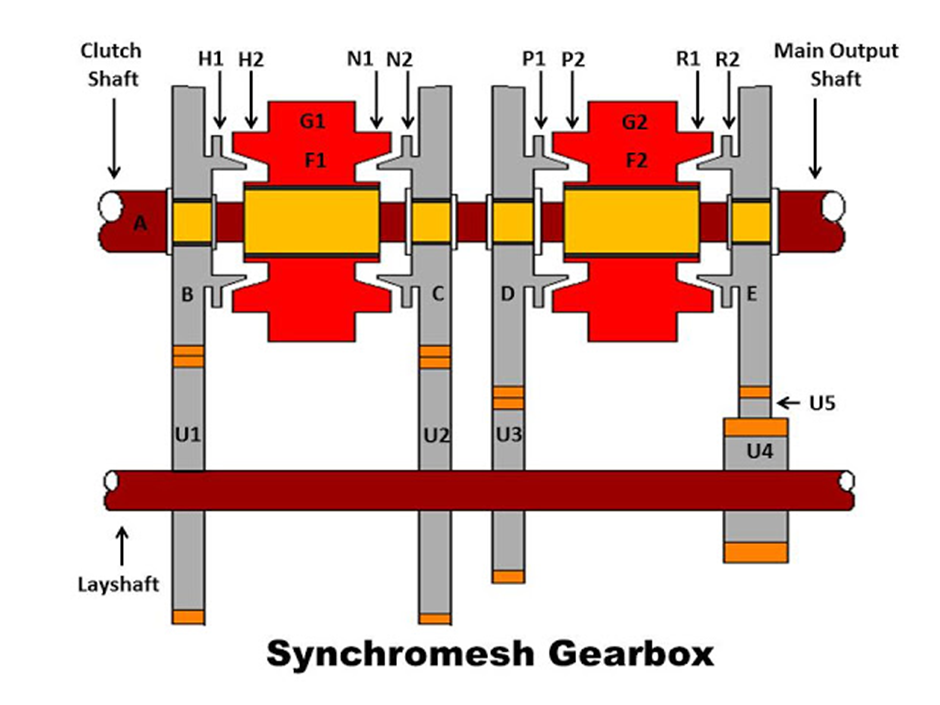

Gears are extensively used in the automotive industry, from the engine to the wheels. The gearbox in a car is an example of a gear system that helps transmit power from the engine to the wheels. Different types of gears, such as spur gears, helical gears, and bevel gears, are used in the transmission system of a car to achieve different gear ratios and speeds.

Industrial Machines

Gears are used in various industrial machines, such as textile machines, printing presses, and machine tools. In these machines, gears are used to transmit power between different parts of the machine, allowing for the smooth and efficient operation of the machine.

Robotics

Gears are extensively used in robotic systems, from industrial robots to household robots. In these systems, gears are used to transmit power between different parts of the robot, allowing for the movement and manipulation of objects.

Household Appliances

Gears are used in various household appliances, such as washing machines, dryers, and blenders. In these appliances, gears are used to transmit power between different parts of the appliance, allowing for the smooth and efficient operation of the appliance.

FAQ

Are there any special types of gear used for specific applications?

Yes, there are specialized gears such as Hypoid gears used in automotive differentials, crown gears used in watches, and harmonic gears used in precision motion control systems. These gears are designed to meet the specific requirements of their respective applications.

What factors should be considered when selecting a gear type for a specific application?

Factors to consider include the required gear ratio, torque and speed requirements, operating conditions (such as temperature and lubrication), space limitations, noise considerations, and cost.

Can you explain the concept of gear ratio?

Gear ratio refers to the ratio of the number of teeth between two meshing gears. It determines the speed and torque relationship between the input and output shafts of a gear system.

What are internal gears used for?

Internal gears have teeth on the inner surface rather than the outer surface. They are often used in applications where space is limited, such as in planetary gear systems and certain types of gearboxes.

What is the purpose of planetary gears?

Planetary gears consist of sun gear, planet gears, and a ring gear. They offer high gear ratios and compact design, making them suitable for applications such as automotive transmissions and robotics.

What are rack and pinion gears used for?

Rack and pinion gears are used to convert rotational motion into linear motion. They are commonly found in steering systems, CNC machines, and various types of linear actuators.

How do worm gears differ from other types of gears?

Worm gears consist of threaded cylindrical gear (worm) and a toothed wheel (worm wheel). They provide high gear ratios and are used when a large reduction in speed and high torque is required.

What are bevel gears used for?

Bevel gears are used to transmit power between intersecting shafts at a specific angle. They are often used in differential gears, power tools, and automotive applications.

What is the difference between spur gears and helical gears?

Spur gears have teeth that are straight and parallel to the gear axis, while helical gears have teeth that are angled or helical, resulting in smoother and quieter operation but increased axial thrust.

Also, read Try Square – Types, Grades, Accuracy, & Applications

Comment on “Types of Gears – Detailed Explanation with Applications”

Comments are closed.