Table of Contents

Introduction

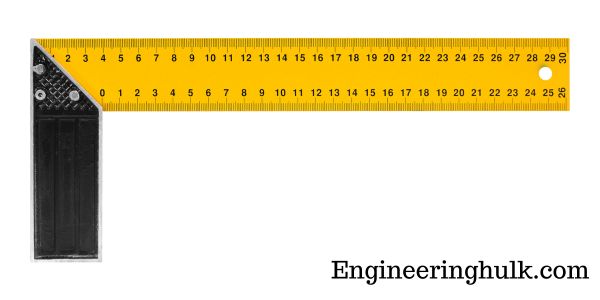

Try square is a popular measuring tool that is widely used in woodworking and metalworking. It is a versatile tool that can be used to check the squareness of corners, edges, and flat surfaces.

Types of Try Squares

1. Steel Try Square: Steel try squares are the most common type of try squares. They are made of high-quality steel and have a blade that is attached to a handle at a 90-degree angle. The blade is marked with both metric and imperial measurements, making it easy to measure accurately.

2. Combination Try Square: Combination try squares are similar to steel try squares, but they come with an additional sliding blade that can be adjusted to any angle between 0 and 180 degrees. This feature makes it easier to measure and mark angles other than 90 degrees.

3. Wooden Try Square: Wooden try squares are traditional tools that are still used by many woodworkers today. They are made of hardwood and have a blade that is held in place with wooden pins. They are less accurate than steel try squares, but they are still useful for rough measurements and marking.

4. Engineer’s Try Square: Engineer’s try squares are large and heavy-duty tools that are used in industrial applications. They are made of cast iron or steel and are designed to withstand rough use in harsh environments. They come in a variety of sizes, from small hand-held tools to large floor-mounted units.

Various grades of try squares and their uses

Try squares come in different grades or levels of accuracy, which can affect the quality of the workpiece being measured.

Grade A Try Square:

Grade A try squares are the most precise type of try square. They have a high degree of accuracy, and their blades are flat to within 0.001 inches per inch. These try squares are ideal for precision work and are commonly used by machinists, engineers, and other professionals who require highly accurate measurements. Grade A try squares are often made of hardened steel, which makes them durable and long-lasting.

Grade B Try Square:

Grade B try squares are slightly less accurate than Grade A try squares. They have a flatness tolerance of 0.002 inches per inch, which makes them suitable for general woodworking tasks. Grade B try squares are commonly used by carpenters and hobbyists who require a reliable and affordable tool for measuring and marking straight lines. They are often made of stainless steel or aluminum, which makes them lightweight and easy to handle.

Grade C Try Square:

Grade C try squares are the least accurate type of try square. They have a flatness tolerance of 0.003 inches per inch, which makes them suitable for rough woodworking tasks. Grade C try squares are commonly used by beginners who require a basic tool for measuring and marking straight lines. They are often made of plastic or low-grade steel, which makes them lightweight and affordable.

How to Check the Accuracy of a Try Square?

To check the accuracy of a try square, you’ll need a flat surface, such as a tabletop or workbench. Place the try square’s blade flush against the surface, and then slide the handle up against the edge of the surface. If the blade is perfectly perpendicular to the surface, the handle should lie flat against the surface as well. If the handle is raised or lowered, then the try square is not accurate.

It’s important to note that the accuracy of a try square can be affected by various factors, such as the quality of the blade and handle, as well as the manufacturing process. Therefore, it’s essential to choose a high-quality try square from a reputable manufacturer to ensure accuracy.

Why is Accuracy Important in Try Square?

The accuracy of a try square is critical for ensuring that your woodworking projects turn out as intended. If your try square is not accurate, then the angles and cuts you make will be off, which can lead to gaps, uneven surfaces, and other problems.

For example, if you’re building a table, and the legs are not cut at a perfect right angle, the table will wobble and be unstable. Similarly, if you’re building a bookshelf, and the shelves are not cut at perfect right angles, the books will not sit properly on the shelves.

Therefore, accuracy is critical when it comes to woodworking, and a high-quality try square is an essential tool for achieving it.

Applications of Try Squares

1. Checking Squareness: The primary use of try squares is to check the squareness of corners, edges, and flat surfaces. This is done by holding the blade against the surface being measured and checking to see if the blade is perpendicular to the surface.

2. Marking Angles: Try squares can also be used to mark angles other than 90 degrees. This is done by using a combination try square or by adjusting the blade of a steel try square to the desired angle.

3. Setting Up Machinery: Try squares are useful for setting up machineries, such as table saws and drill presses. By using a try square to ensure that the blades and fences are square, the accuracy of the machine can be improved.

4. Checking for Warping: Try squares can also be used to check for warping in wood and metal. By holding the blade against the surface being measured, any deviations from a flat surface can be identified.

Also, read the drill bit