Table of Contents

Introduction to Graphene

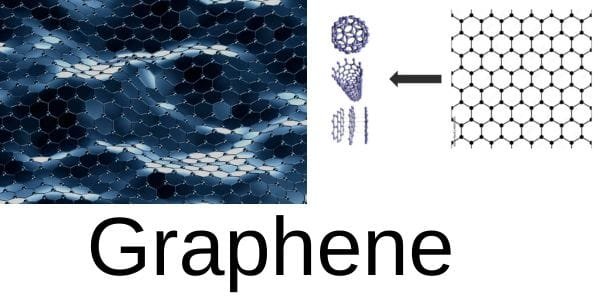

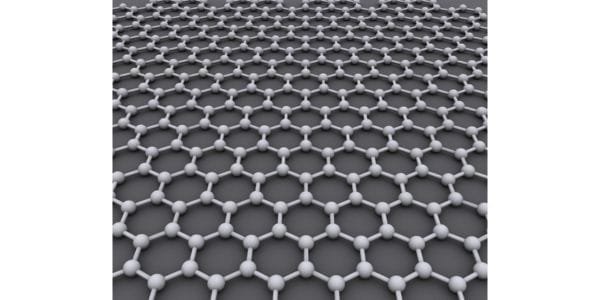

Graphene, a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, has taken the scientific and technological world by storm. Discovered in 2004 by Andre Geim and Konstantin Novoselov at the University of Manchester, graphene has since been hailed as a “wonder material” due to its exceptional properties and wide range of potential applications. This article delves into the fascinating world of graphene, exploring its unique characteristics, production methods, applications, and prospects.

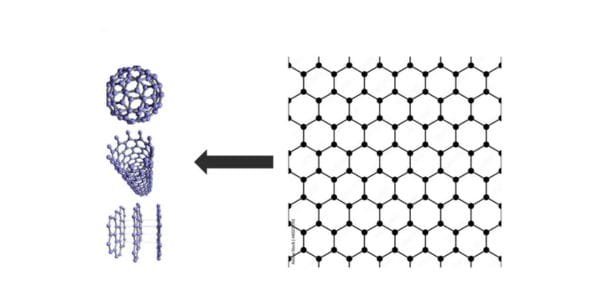

What is Graphene?

Graphene is a form of carbon, similar to graphite but with a distinct structure. While graphite consists of multiple layers of graphene stacked together, graphene itself is a single layer of carbon atoms. Each carbon atom in graphene is bonded to three others, forming a hexagonal lattice that is incredibly strong, lightweight, and conductive.

Key Properties of Graphene

- Strength: Graphene is approximately 200 times stronger than steel, making it one of the strongest materials known to man.

- Flexibility: Despite its strength, graphene is highly flexible and can be stretched without breaking.

- Conductivity: Graphene exhibits excellent electrical and thermal conductivity, surpassing that of copper.

- Transparency: Graphene is nearly transparent, allowing it to be used in applications requiring both conductivity and transparency.

- Lightweight: Being only one atom thick, graphene is incredibly lightweight, making it ideal for applications where weight is a critical factor.

Production Methods of Graphene

The production of graphene is a critical aspect of its utilization. Several methods have been developed to produce graphene, each with its advantages and limitations.

Mechanical Exfoliation

Mechanical exfoliation, also known as the “scotch tape method,” was the technique used by Geim and Novoselov to isolate graphene for the first time. This method involves peeling layers of graphene from graphite using adhesive tape. While it produces high-quality graphene, it is not scalable for industrial applications.

Chemical Vapor Deposition (CVD)

CVD is a widely used method for producing large-area graphene films. In this process, a carbon-containing gas is decomposed on a metal substrate, such as copper or nickel, to form a graphene layer. CVD allows for the production of high-quality graphene suitable for electronic applications.

Chemical Reduction of Graphene Oxide

Graphene oxide (GO) is a derivative of graphene that contains oxygen functional groups. GO can be reduced to produce reduced graphene oxide (rGO), which has properties similar to graphene. This method is cost-effective and scalable, making it suitable for large-scale production.

Epitaxial Growth on Silicon Carbide

Epitaxial growth involves heating silicon carbide (SiC) to high temperatures, causing the silicon atoms to evaporate and leaving behind a layer of graphene. This method produces high-quality graphene but is expensive and limited by the availability of SiC substrates.

Applications of Graphene

The unique properties of graphene make it suitable for a wide range of applications across various industries. Here are some of the most promising applications of graphene:

Electronics and Photonics

Graphene’s excellent electrical conductivity and transparency make it an ideal material for electronic and photonic devices. Some potential applications include:

- Transparent Conductive Electrodes: Graphene can be used as a transparent conductive electrode in touchscreens, displays, and solar cells, replacing indium tin oxide (ITO).

- High-Frequency Transistors: Graphene’s high electron mobility makes it suitable for high-frequency transistors, which are essential for next-generation communication devices.

- Flexible Electronics: Graphene’s flexibility and conductivity enable the development of flexible electronic devices, such as wearable sensors and foldable displays.

Energy Storage and Conversion

Graphene’s high surface area and conductivity make it an excellent material for energy storage and conversion applications. Some potential uses include:

- Supercapacitors: Graphene-based supercapacitors can store and release energy rapidly, making them ideal for applications requiring high power density.

- Batteries: Graphene can be used as an electrode material in lithium-ion batteries, improving their capacity, charge/discharge rates, and lifespan.

- Fuel Cells: Graphene-based catalysts can enhance the efficiency of fuel cells by providing a larger surface area for electrochemical reactions.

Composites and Coatings

Graphene’s strength and lightweight properties make it an excellent additive for composites and coatings. Some potential applications include:

- Reinforced Composites: Graphene can be added to polymers, metals, and ceramics to create stronger and lighter composite materials for use in aerospace, automotive, and construction industries.

- Anti-Corrosion Coatings: Graphene-based coatings can provide superior protection against corrosion, extending the lifespan of metal structures and components.

- Thermal Management: Graphene’s high thermal conductivity makes it suitable for use in thermal management applications, such as heat sinks and thermal interface materials.

Biomedical Applications

Graphene’s biocompatibility and unique properties make it a promising material for biomedical applications. Some potential uses include:

- Drug Delivery: Graphene-based nanomaterials can be used to deliver drugs to specific targets in the body, improving the efficacy and reducing the side effects of treatments.

- Biosensors: Graphene’s high surface area and conductivity make it an excellent material for biosensors, which can detect biomolecules with high sensitivity and specificity.

- Tissue Engineering: Graphene-based scaffolds can promote cell growth and differentiation, making them suitable for tissue engineering and regenerative medicine.

Environmental Applications

Graphene’s unique properties also make it suitable for environmental applications. Some potential uses include:

- Water Purification: Graphene-based membranes can be used for water filtration and desalination, providing a cost-effective and energy-efficient solution for clean water production.

- Air Filtration: Graphene-based filters can remove pollutants and particulate matter from the air, improving air quality and reducing health risks.

- Environmental Sensors: Graphene-based sensors can detect environmental pollutants, such as heavy metals and gases, with high sensitivity and accuracy.

Challenges and Future Prospects

Despite its remarkable properties and potential applications, graphene faces several challenges that need to be addressed for its widespread adoption.

Production Challenges

One of the main challenges in the commercialization of graphene is the development of scalable and cost-effective production methods. While significant progress has been made, further research is needed to optimize production techniques and reduce costs.

Quality Control

The quality of graphene produced can vary significantly depending on the production method and conditions. Ensuring consistent quality is essential for the reliable performance of graphene-based devices and materials.

Integration with Existing Technologies

Integrating graphene with existing technologies and materials can be challenging due to differences in properties and processing requirements. Developing compatible interfaces and fabrication techniques is crucial for the successful integration of graphene into various applications.

Environmental and Health Concerns

The potential environmental and health impacts of graphene need to be thoroughly investigated. While graphene is generally considered safe, further research is needed to understand its long-term effects on human health and the environment.

Future Prospects

Despite these challenges, the future of graphene looks promising. Ongoing research and development efforts are expected to overcome current limitations and unlock the full potential of this remarkable material. As production methods improve and costs decrease, graphene is likely to find its way into a wide range of commercial applications, revolutionizing industries and improving our quality of life.

Also, read

General Engineering Tolerances: Types, Methods & More