Table of Contents

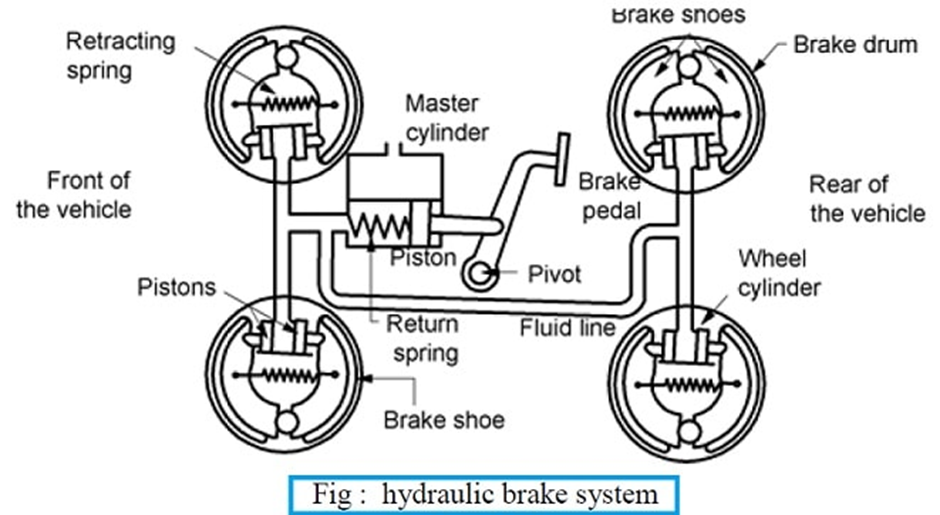

Brakes operated by hydraulic pressure (fluid pressure) are called hydraulic brakes. Hydraulic brakes are commonly used in automobiles. Principle Hydraulic brakes work according to the principle of Pascal’s law, which states that “the pressure at one point in a fluid is the same in all directions in space”. According to this law, when pressure is applied to the fluid, it moves uniformly in all directions, so that a uniform braking action is applied to all four wheels.

Construction and operation of hydraulic brakes

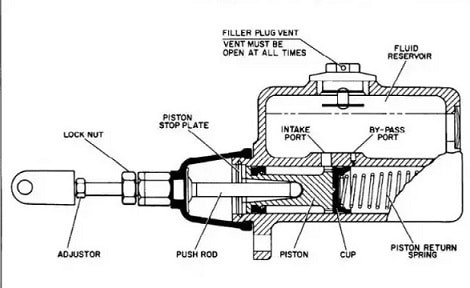

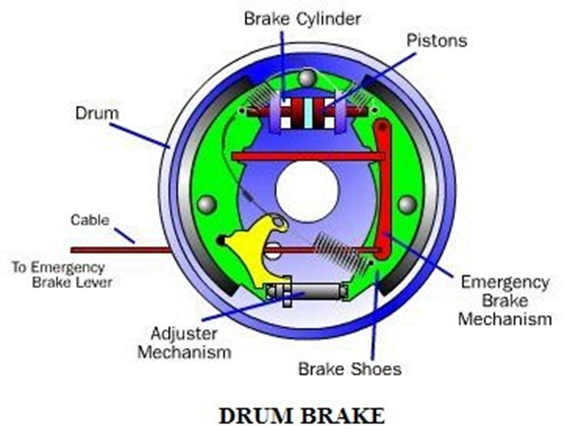

When the brake pedal is depressed, the force is transmitted to the brake shoes via a fluid (link). The pedal force is multiplied and transmitted to all brake shoes by a force transmission system. The figure shows the hydraulic brake system of a four-wheeled car. It consists of a master cylinder, four-wheel cylinders, and lines that transport brake fluid from the master cylinder to a wheel cylinder.

The most common arrangement of hydraulic brakes for passenger vehicles, motorcycles, scooters & mopeds, is as follows:

a) Brake pedal or lever

b) A push rod (also called an actuating rod)

c) A brake cylinder assembly containing a piston assembly (made from either one or two pistons, a return spring, a series of gaskets/ O-rings & a fluid reservoir)

d) Reinforced hydraulic lines) A brake caliper assembly usually consists of 1 or two hollow aluminum or chrome-plated steel pistons (called caliper pistons), a group of thermally conductive restraints, and a rotor (also called a brake disc) or drum attached to an axle.

The master cylinder is connected to all four-wheel cylinders by pipe or pipe. All cylinders and tubes are equipped with a fluid that acts as a link to transmit pedal force from the master cylinder to the wheel cylinders.

Brake fluid: The fluid filled in the hydraulic brake system is known as brake fluid. It is a mixture of glycerine and alcohol or castor oil and some additives.

The master cylinder consists of a piston that is connected to the ring through the connecting rod. The wheel cylinder consists of two pistons between which the liquid is filled. Each wheel brake consists of a cylindrical brake drum. This drum is mounted inside the wheel. The drum turns with the wheel. Two brake shoes mounted inside the drum remain stationary. Heat and wear-resistant brake linings are mounted on the surface of the brake shoes.

Hydraulic brake operation

When you press the brake pedal to apply the brakes, the piston in the master cylinder forces the brake fluid. This increases the pressure of the fluid. This pressure is transmitted in all lines and up to the cylinders of the four wheels according to Pascal’s law. This increase in pressure pushes out the two pistons of the wheel cylinders.

These pistons are connected to the brake shoes. Then the brake shoes expand against the brake drums. Due to friction between the brake pads and drums, the wheels slow down and the brakes are applied.

Operation of the hydraulic brake pump:

1) Brakes applied:

When the brake pedal is actuated, the pushrod moves the piston against the action of the spring force. When sufficient pressure is created, the rubber cap of the fluid check valve flexes and the high-pressure fluid enters the wheel cylinder through the fluid lines and drives the brake shoe against the rotating drum.

2) Brakes released:

When the pedal is released, the piston returns to its initial position under the force of the spring and briefly closes the fluid check valve to prevent air from entering. Fluid from the lines also returns to the compression chamber by lifting the check valve from its seat.

Mechanical Braking System vs Hydraulic Braking System

| Sr. no. | Mechanical Braking System | Hydraulic Braking System |

| 1. | Less Braking efficiency. | More Braking Efficiency. |

| 2. | Poor Anti-fade characteristics | Better Anti-fade characteristics |

| 3. | It does no self-compensate | Simple in construction |

| 4. | More effort is required to brake operation | Self-compensating system |

| 5. | Construction is less flexible | Construction is more flexible |

| 6. | Low mechanical advantage | High mechanical advantage |

| 7. | External Lubrication is required | System is self-lubricating |

| 8. | No leakage problem | Leakage may take place |

| 9. | No hydraulic oil use | Hydraulic oil is used |

| 10. | More effort is required for braking operation | Less effort is required for braking operation |

| 11. | Cheaper | Expensive |

Advantages of Hydraulic Braking System :

The advantages of the hydraulic braking system are as follows,

(a) Equal braking action on all wheels.

(b) Increased braking force.

(c) Simple in construction.

(d) The low wear rate of brake linings.

(e) The flexibility of brake linings.

(f) Increased mechanical advantage.

Disadvantages of Hydraulic Braking System:

The disadvantages of the hydraulic braking system are as follows,

(a) The whole braking system fails due to leakage of fluid from brake linings.

(b) The presence of air inside the tubings ruins the whole system

(c) Maintenance is more than other braking systems.

(d) Construction is complex.

Comment on “Hydraulic Brake System – Construction & Working”