Table of Contents

Introduction

Chemical machining, also known as chemical milling or chemical etching, is a specialized manufacturing process that involves selectively removing material from metal components using chemical reactions. This precise and versatile technique offers several advantages over traditional machining methods.

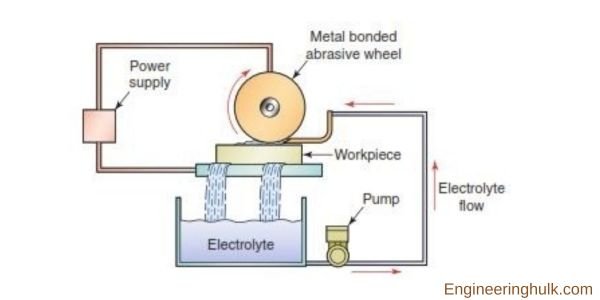

Understanding Chemical Machining

Chemical machining is a subtractive manufacturing process used to shape and pattern metal components through controlled material removal. Unlike conventional machining methods that rely on mechanical forces, chemical machining utilizes chemical etchants to dissolve the unwanted material. This process is particularly effective in creating intricate designs, complex shapes, and fine details with high precision and repeatability.

The Steps in Chemical Machining Process

1. Design and Preparation:

The process begins with designing the desired shape and pattern of the component using computer-aided design (CAD) software. The design takes into account dimensions, tolerances, and surface finish requirements. The CAD file is then converted into a compatible format for chemical machining equipment.

2. Cleaning and Masking:

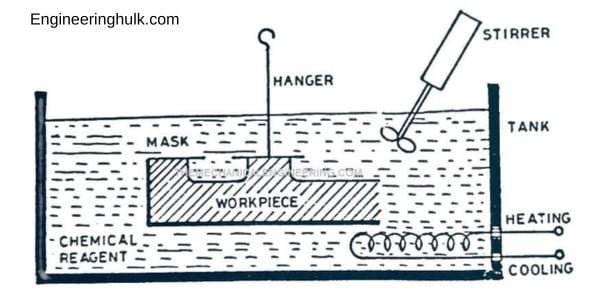

The metal component undergoes thorough cleaning to remove contaminants and ensure a pristine surface. This step involves degreasing to eliminate oils, greases, and other impurities that may interfere with the chemical etching process. After cleaning, a masking material is applied to protect specific areas of the component that should not be etched. Common masking materials include tapes, paints, or photoresists.

3. Etching:

The masked component is immersed in a chemical etchant solution, which selectively removes material from the exposed regions. The etchant’s composition, temperature, and immersion time are precisely controlled to achieve the desired material removal rate and surface finish. Various types of etchants are used depending on the specific metal being machined.

4. Rinse and Post-Etching Treatment:

Once the desired material removal is achieved, the component undergoes a thorough rinsing process to remove any residual etchant. This step is crucial to prevent any potential damage or corrosion. In some cases, post-etching treatments such as passivation, coating, or surface finishing processes may be applied to enhance the component’s properties.

5. Final Inspection and Quality Control:

After the chemical machining process is complete, the component undergoes a comprehensive inspection to ensure it meets the specified requirements. This inspection includes dimensional measurements, surface finish evaluation, and other quality checks. Any deviations or defects are identified and addressed accordingly.

Characteristics of the Chemical Machining

1. Precision Etching:

Chemical machining is a subtractive manufacturing technique that employs a combination of chemical reactions and masking processes to selectively remove material from metal sheets or components. This precision etching allows for the creation of intricate patterns, shapes, and fine details that may be difficult or costly to achieve through conventional machining methods.

2. Versatility:

One of the key advantages of chemical machining is its versatility in handling a wide range of materials, including stainless steel, aluminum, titanium, copper, brass, and exotic alloys. The process can be applied to both metallic and non-metallic materials, making it suitable for diverse manufacturing requirements.

3. Complex Geometries:

The chemical machining process enables the production of components with complex geometries, such as thin-walled structures, microchannels, precision grids, and intricate contours. The ability to achieve such intricate features makes CM particularly valuable in industries like aerospace, electronics, medical devices, and automotive, where intricate and lightweight components are crucial.

4. Cost-Effectiveness:

Chemical machining offers significant cost advantages compared to traditional machining methods, such as milling or turning. The process eliminates the need for expensive tooling, as the chemical etchants selectively remove material without requiring physical contact. This reduces tooling costs, setup time, and material waste, making it an attractive option for large-scale production runs or prototyping.

5. Surface Quality:

The chemical machining process produces components with exceptional surface quality, as the etching process does not introduce mechanical stresses or burrs. The absence of machining marks and tooling-induced imperfections ensures high-quality finishes that often eliminate or minimize the need for additional surface treatment operations, saving time and cost in the manufacturing process.

6. Tolerance and Accuracy:

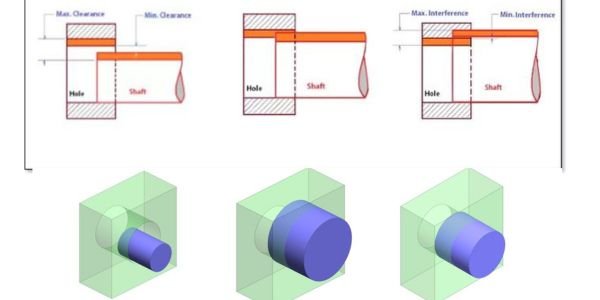

Chemical machining offers excellent dimensional control, enabling the production of components with tight tolerances and high accuracy. The process allows for precise control of material removal rates, ensuring consistent results across multiple production batches. This characteristic is vital in industries that demand stringent tolerances, such as aerospace and electronics, where precision is paramount.

7. Batch Production and Scalability:

Chemical machining is well-suited for both low-volume and high-volume production scenarios. The process can efficiently handle small batch sizes without compromising on cost-effectiveness, making it an ideal choice for prototyping and small-scale production. Moreover, CM is easily scalable, enabling a seamless transition to large-scale production when needed.

Limitations

1. Masking Complexity:

The chemical machining process involves the use of masks or stencils to protect specific areas from etching. The complexity of creating these masks can be a limiting factor, especially for intricate designs or small features, as it requires careful planning and precision in mask fabrication.

2. Material Limitations:

While chemical machining is compatible with a wide range of materials, it may not be suitable for all types of metals or alloys. Some materials may exhibit poor etch ability or require specialized etchants, limiting the range of materials that can be processed through CM.

Applications of Chemical Machining

Chemical machining finds extensive applications in various industries, including:

– Aerospace and Defense:

Used for manufacturing intricate aircraft components, turbine blades, and missile parts with high precision and complex geometries.

– Electronics:

Employed in the production of circuit boards, microelectromechanical systems (MEMS), and semiconductor devices, allowing for miniaturization and precise pattern formation.

– Automotive:

Utilized for manufacturing fuel injection nozzles, clutch plates, and engine components with excellent precision, enhancing performance and fuel efficiency.

– Medical:

Applied in the production of surgical instruments, medical implants, and microfluidic devices, achieving intricate designs and high biocompatibility.

Benefits of Chemical Machining

Chemical machining offers several advantages over traditional machining techniques:

– Precision and Complexity:

It enables the creation of intricate designs, complex shapes, and fine details with tight tolerances, even on thin and delicate materials.

– Cost-effective:

Chemical machining eliminates the need for expensive tooling and complex setups, making it cost-effective for low-volume or prototype production.

– Versatility:

The process works with a wide range of metals and alloys, including stainless steel, aluminum, titanium, and nickel-based alloys.

– Burr-free and Stress-free:

Chemical machining results in burr-free components and does not induce stress or deformation in the material, ensuring high-quality end products.

Also, read the Cornish boiler

Comment on “Chemical Machining Process: Precise Material Removal”

Comments are closed.