Table of Contents

Introduction

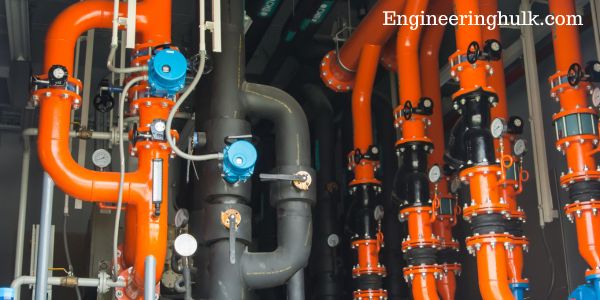

Pumps are mechanical devices that play a crucial role in various industries and applications. They are designed to move fluids, whether liquids or gases, from one place to another. Pumps are essential for processes such as water supply, wastewater treatment, oil and gas extraction, chemical processing, and many more.

There are mainly two types of Pump but they have various categories into it:

1. Dynamic Pump and

2. Positive Displacement Pump

1. Different Types of Dynamic Pumps: Working & Applications

Dynamic pumps are versatile mechanical devices that are widely used in various industries to transport fluids by converting mechanical energy into kinetic energy. These pumps utilize rotating impellers or blades to create fluid flow. Understanding the different types of dynamic pumps, their working principles, and their applications is essential for selecting the right pump for specific needs.

Centrifugal Pumps

Centrifugal pumps are the most common type of dynamic pump used in industrial and commercial settings. These pumps work on the principle of centrifugal force, where the rotation of an impeller increases fluid velocity, generating kinetic energy. This kinetic energy is then converted into pressure energy, enabling the pump to transport the fluid.

Centrifugal pumps are highly efficient and suitable for handling large volumes of fluids at low to medium pressures. They find extensive applications in water supply systems, irrigation, HVAC systems, chemical processing, and wastewater treatment plants.

Axial Flow Pumps

Axial flow pumps, also known as propeller pumps, are designed to move fluids parallel to the pump shaft. These pumps use a rotating propeller-like impeller to generate axial flow. The fluid enters through the center of the impeller and is discharged in the same direction as the impeller rotation. Axial flow pumps are commonly used in applications requiring high flow rates and low to medium pressures, such as flood control, stormwater management, and cooling systems in power plants.

Mixed Flow Pumps

Mixed flow pumps combine the characteristics of both centrifugal and axial flow pumps. They have an impeller with curved blades that enable fluid flow in a combination of radial and axial directions. This design results in a higher pressure rise compared to axial flow pumps while maintaining relatively high flow rates. Mixed flow pumps are suitable for applications such as water supply for tall buildings, irrigation, and drainage systems.

Jet Pumps

Jet pumps, also known as ejector pumps, operate on the principle of creating a high-velocity jet of fluid that entrains and transports the desired fluid. These pumps do not have rotating impellers. Instead, they use the Venturi effect, utilizing a nozzle to accelerate a fluid stream. Jet pumps are often used for pumping fluids with low viscosity, such as water, and can be found in domestic water supply systems, irrigation, and deep well pumping.

Turbine Pumps

Turbine pumps, also called vertical turbine pumps, are specifically designed for pumping fluids from deep wells or reservoirs. These pumps consist of a vertical shaft with multiple impellers, allowing them to operate efficiently at great depths. Turbine pumps are commonly used in agriculture, municipal water supply systems, and oil extraction industries.

Types of Positive Displacement Pumps

Positive displacement pumps are widely used in various industries to move fluids by trapping and displacing a fixed amount of fluid with each pumping cycle. Unlike dynamic pumps, positive displacement pumps provide a steady flow regardless of changes in pressure. Understanding the different types of positive displacement pumps, their working principles, and their applications is crucial for selecting the right pump for specific needs.

1. Reciprocating Pumps

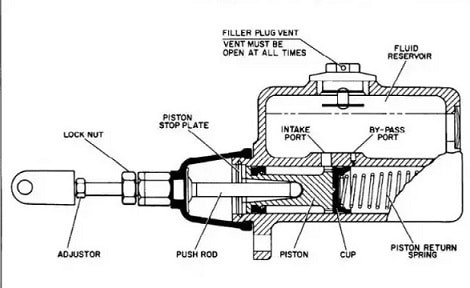

Reciprocating pumps, also known as piston pumps, operate by using a piston or plunger to displace the fluid. The reciprocating motion of the piston creates suction on one side and pressure on the other, allowing the fluid to be pumped. These pumps are capable of delivering high pressures and are commonly used in applications such as hydraulic systems, car washes, high-pressure cleaning equipment, and oil and gas industries.

2. Rotary Pumps

Rotary pumps are designed to deliver a constant flow of fluid by using rotating mechanisms. There are several types of rotary pumps, including:

– Gear Pumps: Gear pumps consist of two meshing gears that create chambers to trap and transport the fluid. They are commonly used in applications where a steady flow rate is required, such as in lubrication systems, hydraulic systems, and fuel transfer.

– Vane Pumps: Vane pumps utilize a rotor with sliding vanes that create chambers to trap and move the fluid. These pumps are known for their ability to handle viscous fluids and are commonly used in food processing, chemical manufacturing, and power steering systems.

– Screw Pumps: Screw pumps use two or more intermeshing screws to move the fluid through the pump. They are suitable for handling fluids with high viscosity and are commonly used in oil refineries, wastewater treatment plants, and the food industry.

3. Diaphragm Pumps

Diaphragm pumps, also known as membrane pumps, use a flexible diaphragm to displace the fluid. The diaphragm moves back and forth, creating suction on one side and pressure on the other, allowing the fluid to be pumped. Diaphragm pumps are often used for metering applications, chemical dosing, and handling corrosive or hazardous fluids. They find applications in industries such as pharmaceuticals, water treatment plants, and laboratories.

4. Peristaltic Pumps

Peristaltic pumps work by squeezing and releasing a flexible tube to move the fluid. The fluid is trapped within the tube, and as the tube is compressed, it pushes the fluid forward. These pumps offer gentle pumping action, making them suitable for delicate fluids and shear-sensitive substances. Peristaltic pumps are commonly used in medical and pharmaceutical industries, laboratory applications, and food processing.

5. Lobe Pumps

Lobe pumps use two or more lobes that rotate in sync to move the fluid through the pump. These pumps are known for their ability to handle viscous and shear-sensitive fluids without causing damage. Lobe pumps are widely used in industries such as dairy processing, cosmetics, and chemical processing.

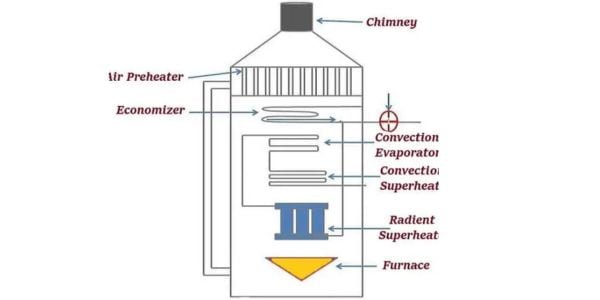

Also, read Benson’s boiler

Comments on “Types of Pumps – A Comprehensive detailed article”

Comments are closed.