Table of Contents

TMT full form?

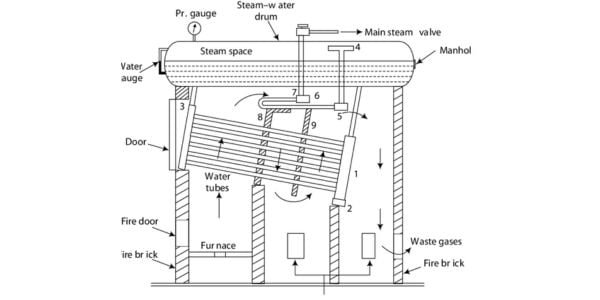

TMT stands for Thermo-Mechanical Treatment. It is a process used in the steel industry to improve the mechanical properties of steel and other metals. The process involves subjecting the steel or other metals to a combination of high temperature and strain.

This combination of temperature and strain causes changes in the microstructure of the material, resulting in improved strength, ductility, hardness, and other properties. The TMT process is used to produce a wide range of steel products, such as automotive parts, structural components, and pipes.

What is the TMT bar?

TMT (Thermo-Mechanically Treated) Bars are high-strength reinforcement bars used in the reinforcement of concrete and masonry structures. These bars are manufactured by a unique technique, which involves the heating and cooling of the bar under controlled conditions.

The heat treatment process imparts superior mechanical properties to the bars, making them tough and pliable, thus allowing them to withstand better the stresses of the environment, such as temperature variations and seismic effects.

The process also increases the bond strength between the bars and concrete, ensuring a strong structure. TMT bars are available in different grades, depending on the application and requirement.

Grade Fe- 415 is the most common grade used in residential structures. Grade Fe- 500 is mainly used in high-rise buildings and grade Fe- 550 is used in bridges and other infrastructure projects. TMT bars are also manufactured in different diameters, ranging from 6mm to 32mm, to suit different applications.

TMT bars are corrosion-resistant due to their superior surface coating, which prevents them from rusting. The bars are also heat resistant, which makes them suitable for use in extreme temperatures. Additionally, the bars can be bent and twisted easily, making them easier to install.

This makes them ideal for earthquake-prone regions, where structures need to be flexible to withstand seismic shocks. TMT bars are an essential part of any reinforced concrete structure, making them one of the most popular reinforcement materials. They offer superior strength and durability, making them an ideal choice for any application, whether residential or industrial.

The Advantages of the TMT bar:

The TMT bar (Thermo-Mechanically Treated) is a type of steel bar that is used in the construction industry. It is used in a wide range of applications, from large-scale commercial projects to residential projects. The bar has a number of advantages over other types of steel bars. Advantages of TMT bars

1. High Strength: TMT bars are made of high-grade steel which makes them highly durable and strong. The bars are also thermally treated which strengthens them even more and makes them resistant to corrosion and fire.

2. Cost-Effective: TMT bars are cost-effective compared to other types of steel bars. They are easier to work with and require less energy to fabricate.

3. High Tensile Strength: TMT bars are made of high-grade steel which makes them highly strong and resistant to breakage or bending. They also have a high tensile strength which makes them ideal for applications where high load-bearing capacity is required.

4. Flexibility: TMT bars are highly flexible and can be bent and shaped into various shapes. This makes them suitable for applications where complex shapes are required.

5. Corrosion Resistance: TMT bars are highly resistant to corrosion and hence are ideal for applications where the bars are exposed to harsh weather conditions.

6. Easy to Handle: TMT bars are lightweight and easy to handle compared to other types of steel bars. This makes them suitable for applications where the bars need to be transported over long distances.

7. Uniformity: TMT bars are made of uniform steel which makes them more reliable and consistent in performance. This also makes them ideal for applications where uniformity is required.

8. Fire Resistance: TMT bars are highly resistant to fire and hence are ideal for applications where fire safety is critical.

These are some of the advantages of using TMT bars in construction projects. The bars are strong, durable, and cost-effective which makes them ideal for a wide range of applications.

The applicability of the TMT bar:

The TMT bar is a highly versatile construction material that has a wide range of applications. The TMT bar, also known as a Thermo-Mechanically Treated bar, is a steel bar that has been subjected to a special heat treatment process called quenching and tempering.

This process increases the strength and ductility of the bar, making it ideal for a variety of construction applications. The TMT bar is commonly used in the construction of residential and commercial buildings, bridges, dams, and other civil engineering projects.

The bar is available in various sizes and grades, depending on the application. Generally, the higher the grade of the bar, the higher its strength and ductility. The TMT bar is also often used in the construction of beams, columns, and other structural members.

It is also used in the construction of reinforced concrete structures such as beams and columns. The bar is also used in the construction of railway tracks and in the manufacture of cranes and lifting equipment. The TMT bar is also often used in the reinforcement of foundation slabs and in the construction of retaining walls.

The bar is also used in the construction of masonry structures such as walls, partitions, arches, and other architectural elements. The bar is also used in the manufacture of industrial products ranging from automobile parts to electrical components.

The TMT bar is a versatile construction material that has a wide range of applications in the construction industry. It is highly resistant to fire, rust, and corrosion, making it suitable for use in a wide range of environments.

The bar is also easy to install and can be cut and bent to fit specific requirements. The bar is also an economical solution for construction projects, as it is cost-effective and requires minimal maintenance.

Which grade of TMT steel is best?

Grade TMT steel is the most commonly used steel in the construction industry. It is a high-strength steel that is used for the construction of buildings, bridges, and other structures. Grade TMT steel is a combination of three different grades of steel – high-strength low-alloy steel, medium-carbon steel, and martensite.

Each grade of TMT steel has its own set of attributes that make it ideal for different applications. High-strength low-alloy steel is the most common grade of TMT steel and is best suited for structures that require high levels of strength and durability. It is also relatively inexpensive compared to other grades of TMT steel.

Medium-carbon steel is the second most common grade of TMT steel and is best for structures that require a combination of strength and flexibility. It is also more expensive than high-strength low-alloy steel. Martensite is the third grade of TMT steel and is the strongest grade of TMT steel available.

It is best suited for structures that require exceptional strength, but it is also the most expensive grade of TMT steel. Overall, the best grade of TMT steel depends on the application and the required strength, durability, and flexibility for the structure.

High-strength low-alloy steel is the most cost-effective option and is suitable for most applications. Medium-carbon steel is a good choice when strength and flexibility are needed, while martensite is best when ultimate strength is required.

The Best TMT brands in India:

One of the most popular and top TMT brands in India is TATA Steel. This company has been around for more than a century and is one of the largest steel producers in the world.

The company has an impressive market share of more than 28% in the Indian steel market and has been the leader in providing high-quality steel products that are used in various industries. Another one of the top TMT brands in India is SAIL.

This company has been around since the early 1950s and is owned by the Government of India. It is the second-largest steel producer in the country and has a market share of more than 15%. It has a wide range of steel products, including hot-rolled coils, cold-rolled coils, and seamless pipes. Essar Steel is another one of the most popular TMT brands in India.

This company is a joint venture between two Indian conglomerates, the Essar Group and the Ruia Group. It is a major producer of flat steel, hot rolled coils, cold rolled coils, and seamless pipes. Essar Steel has a market share of more than 10% and has been a leader in the Indian steel industry for many years. JSW Steel is another popular TMT brand in India.

This company is a part of the JSW Group, which is one of the largest industrial conglomerates in the country. JSW Steel has a market share of more than 8% and is one of the top steel producers in the country.

The company manufactures a wide range of steel products, including hot-rolled coils, cold-rolled coils, and seamless pipes. The last of the top TMT brands in India is Bhushan Steel.

This company is a part of the Bhushan Group and is the third-largest steel producer in the country. It has a market share of more than 7% and is known for providing high-quality steel products. Bhushan Steel manufactures a wide range of steel products, including hot-rolled coils, cold-rolled coils, and seamless pipes.

Q1. What is TMT?

TMT stands for Thermo-Mechanical Treatment. It is a process that uses heat and mechanical force to improve the properties of metals and alloys. The process involves heating the metal to a certain temperature, then applying mechanical force to it, such as hammering or rolling. This process is used to enhance the strength and toughness of the metal, as well as improve its wear resistance and corrosion resistance.

Q2. What are the benefits of TMT?

TMT offers several benefits, including improved strength, toughness, wear resistance, and corrosion resistance. The process can also reduce the cost of production, as it reduces the amount of metal that needs to be used for a given application. Additionally, TMT can reduce the risk of failure due to the improved properties of the metal.

Q3. What metals can be treated with TMT?

TMT can be used on a variety of metals, including steel, stainless steel, aluminum, and titanium.

Q4. What is the process of TMT?

The TMT process involves heating the metal to a certain temperature, then applying mechanical force to it, such as hammering or rolling. This process helps improve the strength and toughness of the metal, as well as improve its wear resistance and corrosion resistance.

Q5. How long does TMT take to complete?

The time required to complete the TMT process depends on the type of metal being treated and the desired results. Generally, the process can take anywhere from a few hours to several days.

Also, read Requirements of Brake System in Automobiles

Comments on “TMT full form”

Comments are closed.