Table of Contents

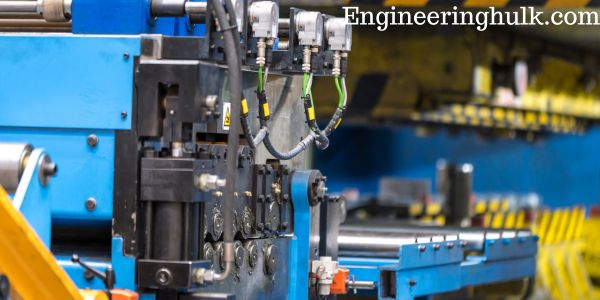

Punching machines are an important part of mechanical engineering that is used in various industries. They are powerful machines that are designed to punch holes, slots, and shapes in various materials such as metal, plastic, and wood.

What is a Punching Machine?

A punching machine is a type of mechanical equipment used for punching holes in various materials. The machine consists of a punch and a die that are used to cut holes and shapes in the material. Punching machines are commonly used in manufacturing, construction, and metalworking industries.

How Does a Punching Machine Work?

The punching machine works by applying pressure to the material through a punch and a die. The punch is a tool that is placed on top of the material, and the die is placed underneath it. When the punch is pressed against the die, it cuts a hole or shape in the material.

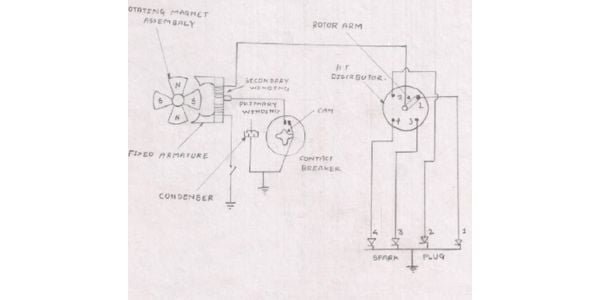

The punching machine can be powered by various sources, including hydraulic, mechanical, and pneumatic systems. Hydraulic systems are the most commonly used, as they provide high-pressure output and can handle heavy loads.

The hydraulic system is powered by a motor, which drives a pump that generates hydraulic pressure. The pressure is then transmitted to the punch and die through a hydraulic cylinder.

The essential parts of punching machines

1. Base and Frame:

The base and frame are the foundation of the punching machine. They provide the stability needed for the machine to operate efficiently. The base and frame also protect the machine from external forces and vibrations that may affect its operation. The base and frame are usually made of high-quality materials like cast iron or steel to withstand high pressure and stress during operation.

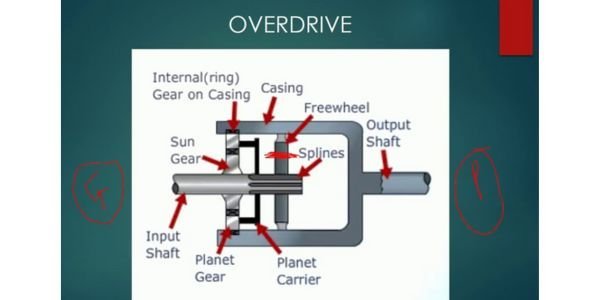

2. Drive Mechanism:

The drive mechanism of a punching machine is responsible for transferring power from the motor to the punching tool. The drive mechanism is usually composed of gears, belts, and pulleys that transmit power and motion from the motor to the punch head.

3. Punch Head:

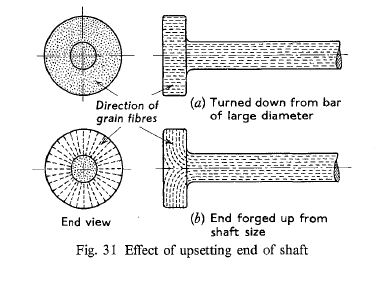

The punch head is the part of the punching machine that performs the punching or cutting action. The punch head is typically mounted on the top of the machine and moves up and down to apply the force required to punch or cut the material. The punch head is usually made of high-strength steel to withstand the pressure and stress generated during operation.

4. Die:

The die is a stationary component of the punching machine that provides the support and resistance needed to punch or cut the material. The die is typically made of high-strength steel and has a hole or cavity that matches the shape of the punch head.

The material to be punched or cut is placed between the punch head and the die, and when the punch head applies force, the material is punched or cut according to the die’s shape.

5. Clutch:

The clutch is a mechanical component that allows the operator to control the machine’s operation. The clutch can engage or disengage the drive mechanism, depending on the operator’s needs. When the clutch is engaged, the punch head moves up and down, and when the clutch is disengaged, the punch head remains stationary.

6. Control Panel:

The control panel is the interface between the operator and the punching machine. It contains the buttons, switches, and indicators that the operator uses to control the machine’s operation. The control panel may also include a display screen that shows the machine’s status, such as the number of punches or cuts performed and the machine’s power consumption.

7. Lubrication System:

The lubrication system is responsible for keeping the machine’s moving parts lubricated and reducing friction and wear. The lubrication system typically consists of a pump, reservoir, and distribution system that delivers oil or grease to the machine’s moving parts.

Types of punching machines:

1. Hydraulic Punching Machine

Hydraulic punching machines are powerful machines that use hydraulic pressure to punch holes in materials. These machines are widely used in the metalworking industry due to their ability to create clean and precise holes.

Hydraulic punching machines are available in different sizes, and they can punch through thick materials quickly and efficiently. These machines can also be programmed to create specific hole patterns, making them ideal for mass production.

2. Mechanical Punching Machine

Mechanical punching machines are powered by a mechanical drive system, making them more affordable than hydraulic punching machines.

These machines are capable of producing holes in various materials, including metal and plastic. They are widely used in the automotive industry, where they are used to create holes in car body panels and other components.

3. CNC Punching Machine

CNC punching machines are advanced machines that are computer-controlled. They are used to create complex shapes and patterns in materials, including metal and plastic. These machines are ideal for mass production as they can be programmed to create identical shapes and patterns repeatedly. CNC punching machines are also highly accurate and can produce high-quality finished products.

4. Portable Punching Machine

Portable punching machines are lightweight and easy to use. They are used to create holes in materials in areas where a larger punching machine would not be practical. These machines are ideal for small workshops and DIY projects. Portable punching machines are available in both manual and automatic versions, making them suitable for a wide range of applications.

5. Single Punch Machine

Single-punch machines are basic punching machines that are used to create holes in materials. They are easy to use and require minimal maintenance. Single-punch machines are widely used in the construction industry, where they are used to create holes in metal sheets and other building materials.

6. Multiple Punch Machine

Multiple punch machines are similar to single punch machines but have the ability to create multiple holes simultaneously. These machines are ideal for mass production as they can create several holes in a single pass. Multiple punch machines are widely used in the automotive industry, where they are used to create holes in car body panels and other components.

Advantages of Punching Machines

1. High Precision: Punching machines are designed to cut holes and shapes with high precision. They are accurate and reliable, which makes them ideal for manufacturing applications where precision is critical.

2. High Speed: Punching machines can punch holes and shapes quickly, making them ideal for mass production.

3. Versatility: Punching machines can be used to cut holes and shapes in a wide range of materials, including metal, plastic, and wood.

4. Low Cost: Punching machines are relatively inexpensive compared to other types of cutting machines, such as laser cutters or water jets.

Disadvantages of Punching Machines

1. Limited Flexibility: Punching machines are limited to cutting holes and shapes in a straight line. They cannot be used to cut complex shapes or contours.

2. Noise: Punching machines can produce a lot of noise during operation, which can be a nuisance in some environments.

3. Maintenance: Punching machines require regular maintenance to ensure they are operating at peak efficiency. This can be time-consuming and expensive.

Applications of Punching Machines

Punching machines are used in various industries, including:

1. Manufacturing: Punching machines are used to cut holes and shapes in metal sheets, which are then used in the manufacturing of products such as car parts, electronic devices, and appliances.

2. Construction: Punching machines are used to punch holes in steel beams and columns, which are then used in construction projects.

3. Signage: Punching machines are used to cut letters and shape out of metal sheets, which are then used in signage and advertising.

4. Packaging: Punching machines are used to cut holes in cardboard boxes, which are then used for packaging products.

Also, read Drill Machine

Comment on “Punching Machine – Working, Types, and Applications”

Comments are closed.