Table of Contents

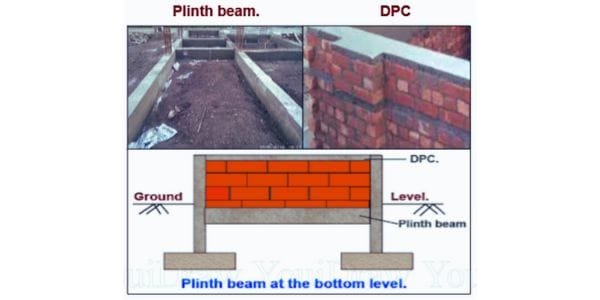

In civil construction, structural integrity is paramount. One of the most important structural components that secures the strength and stability of a building is the plinth beam. Often overlooked by laypersons, this horizontal element plays a critical role in safeguarding a structure from foundational shifts, environmental stress, and load imbalances.

Positioned between the substructure and superstructure, the plinth beam serves as a connecting element that strengthens the building’s foundation and helps evenly distribute the structural load. Understanding the purpose, design considerations, materials used, and benefits of plinth beams is essential for anyone involved in building construction.

What is a Plinth Beam?

A plinth beam is a reinforced concrete beam constructed at the plinth level—the level that separates the foundation from the wall of the superstructure. It runs horizontally along the perimeter of the building and connects all the columns above the ground level. This beam acts as a support system that distributes the load of the wall uniformly to the foundation while also preventing differential settlement and protecting against soil movements.

In most buildings, the plinth beam is constructed after the foundation is laid and before the walls of the ground floor are erected. It essentially forms a base over which the masonry walls are built.

Importance of the Plinth Beam

1. Prevents Differential Settlement: The plinth beam ensures that loads from the superstructure are evenly distributed to the foundation, thereby minimizing the chances of differential settlement. Irregular settlement can cause cracks in the walls and unevenness in the flooring, potentially compromising the overall stability of the structure.

2. Acts as a Flood Barrier: In flood-prone areas or regions with poor drainage, water tends to collect around the foundation. The plinth beam, constructed above the ground level, helps raise the building floor, offering protection from water seepage and dampness.

3. Resists Earthquake Forces: In seismic zones, buildings without proper reinforcement are vulnerable to lateral movements. A plinth beam ties all the columns together, providing a uniform base and enhancing the building’s ability to resist seismic forces.

4. Provides a Base for Walls: The beam offers a consistent and sturdy platform for constructing masonry walls. Since it is a reinforced concrete member, it has higher compressive and tensile strength compared to ordinary masonry, offering better support to the walls above.

5. Protects from Termite Attack: Constructing a plinth beam can act as a barrier to termites and other ground-dwelling pests, as concrete is not a favorable medium for such organisms to penetrate.

Construction of a Plinth Beam

1. Site Preparation: Before starting the construction, the spot is cleared of loose soil and leveled. Proper formwork is set up based on the design and dimensions of the plinth beam.

2. Reinforcement: Steel reinforcement bars (rebars) are tied according to the structural design. This typically includes two or more longitudinal bars supported by stirrups spaced at regular intervals.

3. Framework: Framework is used to shape and hold the wet concrete in place until it hardens. It is commonly made of wood, steel, or plastic.

4. Concrete Pouring: Concrete of the required mix (typically M20 or M25) is poured into the formwork. It must be vibrated properly to eliminate air voids and ensure uniform compaction.

5. Curing: After the concrete sets, the beam is cured for 7 to 14 days to achieve the required strength and to prevent shrinkage cracks.

Design Considerations

The design of a plinth beam is usually done by structural engineers and takes into account several factors:

Structural Load: The anticipated weight imposed by the walls and the superstructure above.

Soil Type: Loose or expansive soils may require deeper or wider plinth beams.

Seismic Zone Classification: In earthquake-prone areas, stronger reinforcement and higher-grade concrete may be specified.

Span and Dimensions: The span between columns determines the beam’s size and reinforcement.

Material Quality: Both the quality of cement, aggregates, and reinforcement steel must conform to standards like IS 456:2000 (in India).

Typically, “the minimum size of a plinth beam is 225 mm x 300 mm, but this may vary depending on the design and load conditions”.

Materials Used in Plinth Beam Construction

1. Cement: Portland Pozzolana Cement (PPC) or Ordinary Portland Cement (OPC) is typically utilized.

2. Coarse and Fine Aggregates: Clean and well-graded aggregates enhance the strength and durability of the concrete mix.

3. Water: Water should be clean and free from impurities. The water-cement ratio must be maintained as per design.

4. Reinforcement Steel: High-yield strength deformed (HYSD) bars or TMT bars are used for better ductility and bonding with concrete.

Types of Plinth Beams

Although most plinth beams follow a similar design principle, their construction and purpose might vary slightly depending on building requirements:

1. Plain Plinth Beam: This type of concrete beam, either unreinforced or minimally reinforced, is typically employed in situations with low load requirements.

2. Reinforced Plinth Beam: Heavily reinforced to support larger loads and to tie the building columns firmly. It’s the most commonly used type in modern construction.

3. Integrated Plinth Beam with Grade Slab: In some cases, the plinth beam is integrated with the ground slab to form a monolithic element, enhancing load distribution.

Common Mistakes During Plinth Beam Construction

Inadequate Reinforcement: Using undersized or fewer bars than required weakens the structure.

Poor Curing: Inadequate curing can lead to shrinkage cracks and reduced strength.

Improper Concrete Mix: Deviating from the specified mix ratio can compromise structural performance.

Formwork Failures: Improper or unstable formwork may lead to cracks or irregularities in the beam structure.

Lack of Alignment: Misalignment affects the proper load transfer and can cause wall cracks.

Regulatory Guidelines

In India, guidelines for plinth beam construction are provided in IS codes, such as:

IS 456:2000 – Guidelines for Plain and Reinforced Concrete Structures.

IS 875 – Code for Load Calculations in Building Design.

NBC (National Building Code) – Provides extensive construction practices.

Similar standards exist in other countries, like ACI (American Concrete Institute) codes in the U.S., or Eurocodes in Europe.

Maintenance and Inspection

Although plinth beams are not typically visible once the structure is complete, periodic inspection is necessary to detect issues such as:

Cracks due to settlement or shrinkage

Corrosion of reinforcement due to water seepage

Termite infestations near the plinth level

Proper waterproofing, drainage, and termite control measures help prolong the life of plinth beams.

Summary about Plinth beam

Plinth beams may not be the most visible or decorative parts of a building, but their role is fundamental in ensuring long-term stability and performance. From providing a base for walls to preventing differential settlements and enhancing earthquake resistance, the plinth beam is an unsung hero in civil construction.

A structurally sound plinth beam, designed and built as per engineering standards, not only improves the durability of a building but also enhances its safety. As urbanization increases and construction challenges grow, incorporating robust plinth beam systems remains a best practice for every civil engineer and builder.

Also read about Bioengineering: A Modern Fusion of Biology and Engineering