Table of Contents

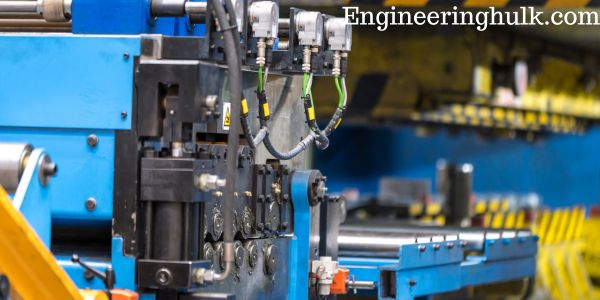

The following steps must be performed for the successful operation of the NC machine tool.

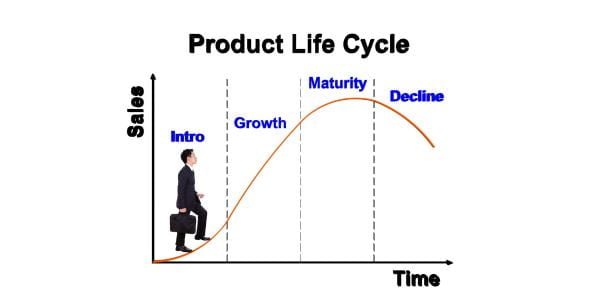

1. Process Planning

The design of the work to be manufactured must be interpreted in terms of the manufacturing processes that must be performed on the work. The process of interpreting the engineering drawing in the manufacturing process is known as process planning. Process planning is concerned with preparing the route sheet.

The routing sheet lists the sequence of operations required to be performed on the job to obtain the desired end product. The term routing sheet is justified as it also lists the machines the job must be routed through to perform the listed machining operations. It may be possible for a single NC machine to perform one or more operations.

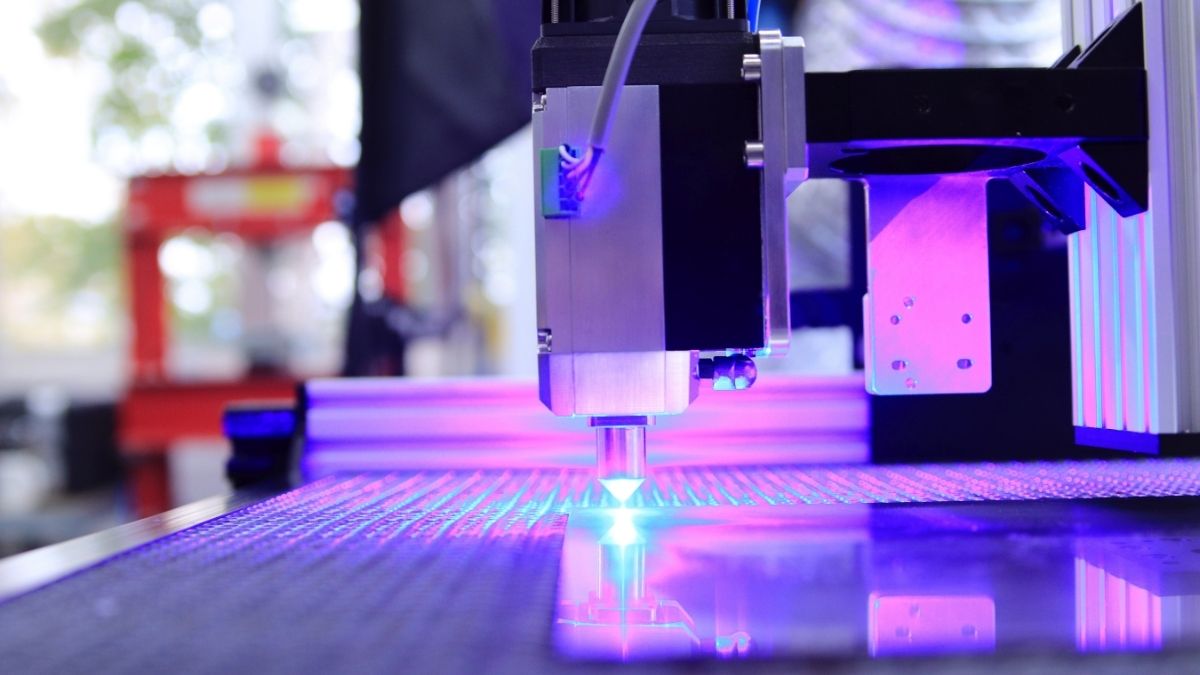

2. Parts Programming

There are usually two methods for programming the NC machine: Manual and computer-aided. Program instructions are prepared in a form in the case of manual part programming. This form is known as the part program manuscript. The instructions in the program script list the relative position of the machine and cutter according to the machining operation that is to be performed.

In the case of computer-aided parts programming, the tedious task of computational work is transferred to the computer. Computer-aided part programming is particularly suited for complex geometries and jobs involving multiple machining operations. Using computers for programming saves a lot of time and improves accuracy.

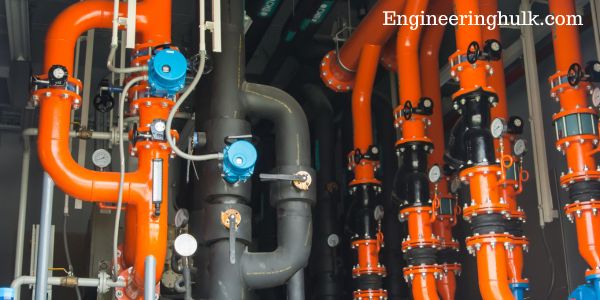

3. Tape preparation

The perforated tape is prepared using NC part programming and process planning prepared by the NC operator. A typewriter-like device capable of punching the tape is used to prepare the tape in the case of manual part programming. The part programming prepared in the program script is used directly.

However, in the case of programming computer parts, the computer interprets the programming instructions, converts the instructions into useful machine tool motion by performing the necessary calculations, and finally prepares the tape controlling the punching device. Prepared tape can be used for machine N.

4. Tape Verification

The prepared tape is then checked for part program accuracy. Several methods are available to accomplish this task. One method involves running the prepared tape through a computer program that plots the different movements of the tool and table on a piece of paper. This results in any errors being identified in the part program.

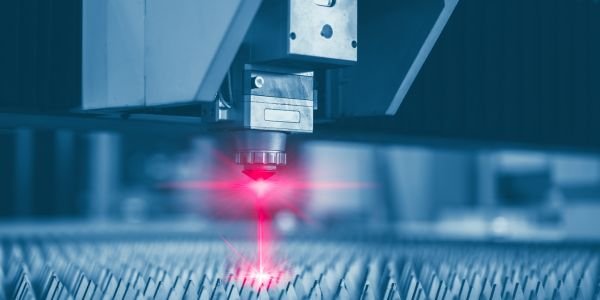

5. Production

The final step involves using NC tape to produce the part. The tasks involved include ordering the necessary raw materials, preparing the necessary tooling, and any other arrangements necessary to set up the NC machine tool for the job. The operator’s role is only to load the blank into the machine.

The starting position of the cutting tool in relation to the workpiece must also be specified by the operator. The NC machine then executes according to the loaded part schedule. The operator then removes the part from the machine on completion.

Comment on “Numerical Control (NC) Procedure”