Table of Contents

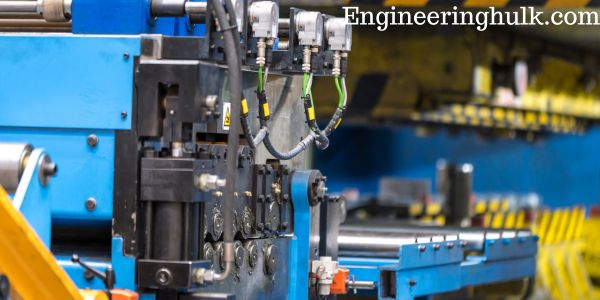

Drilling machines are one of the most important tools in mechanical engineering. They are used to create holes in a variety of materials, including metal, wood, plastic, and stone. These machines are essential for manufacturing, construction, and repair projects.

What is a drilling machine?

A drilling machine is a tool used to create holes in various materials. It uses a cutting tool called a drill bit to remove material from the workpiece. The drill bit rotates at high speed while applying downward pressure, allowing it to cut through the material. Drilling machines can be operated manually or with the help of a computer program.

How does a drilling machine work?

Drilling machines work by rotating the drill bit and applying downward pressure on the workpiece. The drill bit is mounted on a spindle, which is powered by an electric motor. The workpiece is held in place by a clamp or a vise, which keeps it stable during the drilling process. The operator then adjusts the speed and feed rate of the drill bit to control the depth and diameter of the hole.

Types of drilling machines:

Benchtop drilling machine

Benchtop drilling machines are small, compact machines that can be mounted on a workbench or table. They are commonly used in home workshops, small businesses, and hobbyists. They are suitable for drilling small holes in wood, plastic, and soft metals.

Upright drilling machine

Upright drilling machines are larger and more powerful than benchtop models. They are used for drilling larger holes and are commonly found in manufacturing facilities and construction sites. They can be operated manually or with the help of a computer program.

Radial drilling machine

Radial drilling machines are designed for drilling large and heavy workpieces. They have an arm that can be moved horizontally and vertically, allowing the operator to position the drill bit at any angle. They are commonly used in construction and metalworking.

Handheld or portable Drill Machines:

Handheld drill machines are the most common and basic type of drill machine. These machines are designed for light-duty applications such as drilling holes in wood, plastic, and soft metals. Handheld drill machines are available in both corded and cordless models. Cordless models use batteries as a power source, making them more portable and convenient.

Applications:

Handheld drill machines are ideal for tasks like drilling pilot holes, hanging shelves, and installing light fixtures.

Hammer Drill Machines:

Hammer drill machines, also known as percussion drills, are designed for heavy-duty drilling tasks. These machines use a pulsating mechanism to deliver a hammering action to the drill bit, allowing it to drill through hard surfaces like concrete and masonry. Hammer drill machines are available in both corded and cordless models.

Applications:

Hammer drill machines are ideal for drilling holes in concrete, brick, and other hard materials.

Drill Press Machines:

Drill press machines, also known as bench drill machines, are stationary machines that are bolted to a workbench or floor. These machines use a motor to rotate the drill bit, allowing for precise drilling operations. Drill press machines are available in both floor and benchtop models.

Applications:

Drill press machines are ideal for precise drilling operations that require a high degree of accuracy. They are commonly used in metalworking and woodworking applications.

Magnetic Drill Machines:

Magnetic drill machines, also known as mag drills, are designed for drilling holes in large and heavy pieces of metal. These machines use powerful magnets to hold the drill in place while it drills through the metal. Magnetic drill machines are available in both portable and stationary models.

Applications:

Magnetic drill machines are ideal for drilling holes in large and heavy pieces of metal, such as steel beams and pipes.

Impact Drill Machines:

Impact drill machines are designed for heavy-duty drilling and screw-driving applications. These machines use a mechanism that delivers a rapid series of impacts to the drill bit, allowing it to easily penetrate tough materials. Impact drill machines are available in both corded and cordless models.

Applications:

Impact drill machines are ideal for drilling and driving screws through hard materials like metal, concrete, and brick.

CNC drilling machines

These machines are fully automated and are capable of drilling multiple holes with high precision and accuracy. They are often used in large-scale manufacturing operations.

Applications of Drilling Machines

Drilling machines are used in a wide range of applications in various industries, including manufacturing, construction, and woodworking. Some of the most common applications of drilling machines include:

1. Metalworking – Drilling machines are used to create holes in metal parts for assembly or to create threaded holes for fasteners.

2. Woodworking – Drilling machines are used to create holes in wooden parts for assembly or to create decorative holes for design purposes.

3. Construction – Drilling machines are used to create holes in concrete, masonry, and other building materials for the installation of pipes, wires, and other fixtures.

4. Mining – Drilling machines are used in the mining industry to create holes for blasting, exploration, and other purposes.

5. Automotive – Drilling machines are used in the automotive industry to create holes for the installation of various components, such as engines, transmissions, and exhaust systems.

Also, read the press machine