Table of Contents

Introduction

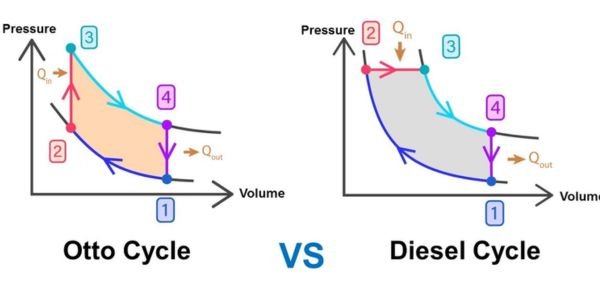

The Otto cycle and the Diesel cycle are two fundamental thermodynamic cycles that dictate the operation of internal combustion engines. These cycles play a crucial role in the functioning of gasoline and diesel engines, respectively.

The Otto Cycle

The Otto cycle, named after Nikolaus Otto, represents the idealized thermodynamic cycle for spark-ignition (SI) gasoline engines. By examining the PV and TS diagrams, we can gain a deeper understanding of their four distinct processes: intake, compression, combustion, and exhaust.

a. Intake Process:

In the intake stroke, the piston moves from the top dead center (TDC) to the bottom dead center (BDC), and the intake valve opens. As shown on the PV diagram, the pressure remains relatively constant while the volume increases as air and fuel are drawn into the cylinder.

b. Compression Process:

During the compression stroke, the piston moves from BDC to TDC, compressing the fuel-air mixture. On the PV diagram, this process is represented by a steep upward slope as the volume decreases, leading to a significant increase in pressure.

c. Combustion Process:

When the piston reaches TDC, the spark plug ignites the compressed fuel-air mixture, initiating combustion. This causes a rapid increase in pressure and temperature, resulting in a sharp rise in both the PV and TS diagrams.

d. Exhaust Process:

After the power stroke, the exhaust valve opens, and the piston moves from TDC to BDC, expelling the combustion byproducts. On the PV diagram, the pressure drops as the volume increases during the exhaust stroke.

The Diesel Cycle:

The Diesel cycle, named after Rudolf Diesel, describes the idealized thermodynamic cycle employed by compression-ignition (CI) diesel engines. Let’s examine the PV and TS diagrams to comprehend their four processes: intake, compression, combustion, and exhaust.

a. Intake Process:

Similar to the Otto cycle, the intake stroke in the Diesel cycle involves the downward movement of the piston, drawing air into the cylinder. The PV diagram depicts a gradual increase in volume and a relatively constant pressure.

b. Compression Process:

During the compression stroke, the piston moves from BDC to TDC, compressing only the air. The PV diagram shows a steep upward slope, indicating a significant increase in pressure as the volume decreases.

c. Combustion Process:

At the end of the compression stroke, fuel is injected directly into the hot, highly compressed air. This mixture auto ignites due to the high temperature and pressure, leading to combustion. On the PV and TS diagrams, a sharp rise in pressure and temperature signifies this process.

d. Exhaust Process:

Following the power stroke, the exhaust valve opens, and the piston moves from TDC to BDC, expelling the combustion byproducts. The PV diagram shows a decrease in pressure as the volume increases during the exhaust stroke.

Key Differences and Applications:

1. Fuel Ignition:

The primary difference between the Otto and Diesel cycles lies in their fuel ignition methods. The Otto cycle utilizes a spark plug to ignite the premixed fuel-air mixture, while the Diesel cycle relies on compression ignition without a spark plug.

2. Compression Ratio:

Diesel engines typically have higher compression ratios than gasoline engines. This higher compression ratio leads to improved thermal efficiency and greater power output in diesel engines.

Applications of the Otto Cycle and Diesel Cycle

1. Applications of the Otto Cycle:

The Otto cycle, which powers spark-ignition (SI) gasoline engines, has a wide range of applications in transportation and other sectors. Let’s delve into some of its primary applications:

a. Passenger Vehicles:

Gasoline-powered passenger cars heavily rely on the Otto cycle for their operation. The cycle’s efficiency, combined with the availability of gasoline fuel, makes it the preferred choice for most personal vehicles. Otto cycle engines offer a smooth and responsive driving experience, making them ideal for everyday commuting.

b. Motorcycles and Scooters:

Similar to passenger vehicles, motorcycles, and scooters often utilize the Otto cycle. The compact size and lighter weight of these vehicles make them suitable for smaller, more efficient gasoline engines, resulting in enhanced fuel economy and maneuverability.

c. Small Aircraft:

Many small aircraft engines are based on the Otto cycle. These engines provide the necessary power and reliability for light aircraft operations, such as recreational flying, flight training, and aerial photography. The Otto cycle’s ability to deliver consistent performance at various altitudes makes it an optimal choice for this application.

d. Power Equipment:

Portable generators, lawnmowers, and other power equipment often feature Otto cycle engines. These engines provide the necessary power for outdoor and emergency use. Their ability to start quickly and deliver consistent power output makes them well-suited for these applications.

2. Applications of the Diesel Cycle:

The Diesel cycle, employed in compression-ignition (CI) diesel engines, has a distinct set of applications due to its inherent advantages. Let’s explore some key areas where the Diesel cycle is commonly utilized:

a. Heavy-Duty Vehicles:

One of the prominent applications of the Diesel cycle is in heavy-duty vehicles, such as commercial trucks, buses, and construction equipment. The Diesel cycle’s high compression ratio and efficient fuel combustion enable these engines to deliver substantial torque and power, making them ideal for heavy hauling and towing.

b. Marine Industry:

Diesel engines based on the Diesel cycle are extensively used in the maritime sector. From large ships and tankers to recreational boats and yachts, diesel engines provide the required propulsion and auxiliary power. The Diesel cycle’s robustness, fuel efficiency, and durability make it well-suited for maritime applications.

c. Power Generation:

Diesel generators play a critical role in backup power supply and remote area electrification. These generators utilize the Diesel cycle to convert diesel fuel into electrical energy efficiently. Their ability to operate for extended periods and their reliability makes them suitable for applications in hospitals, data centers, construction sites, and areas with unreliable grid connections.

d. Industrial and Agricultural Machinery:

Diesel engines are commonly found in various industrial and agricultural machinery, including tractors, excavators, pumps, and compressors. The Diesel cycle’s ability to handle heavy loads, deliver high torque, and operate under harsh conditions makes it an ideal choice for these applications.

Also, read Casting Process

Comment on “Otto cycle and diesel cycle”

Comments are closed.