Table of Contents

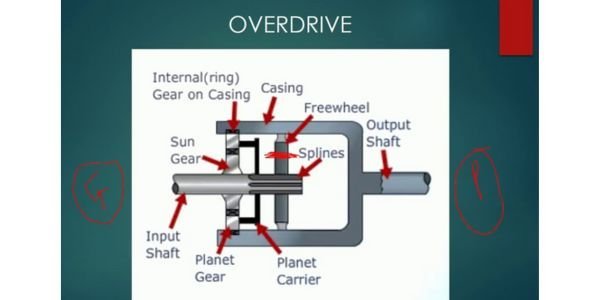

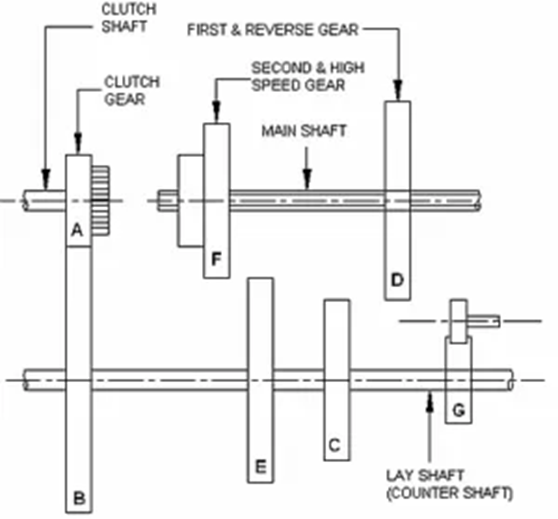

This is a manually operated transmission in which transmission changes occur between gears rotating at the same speed. The gears can roll freely or can be locked onto the layout shaft in this type of gearbox.

Synchromesh Gear Box Construction:

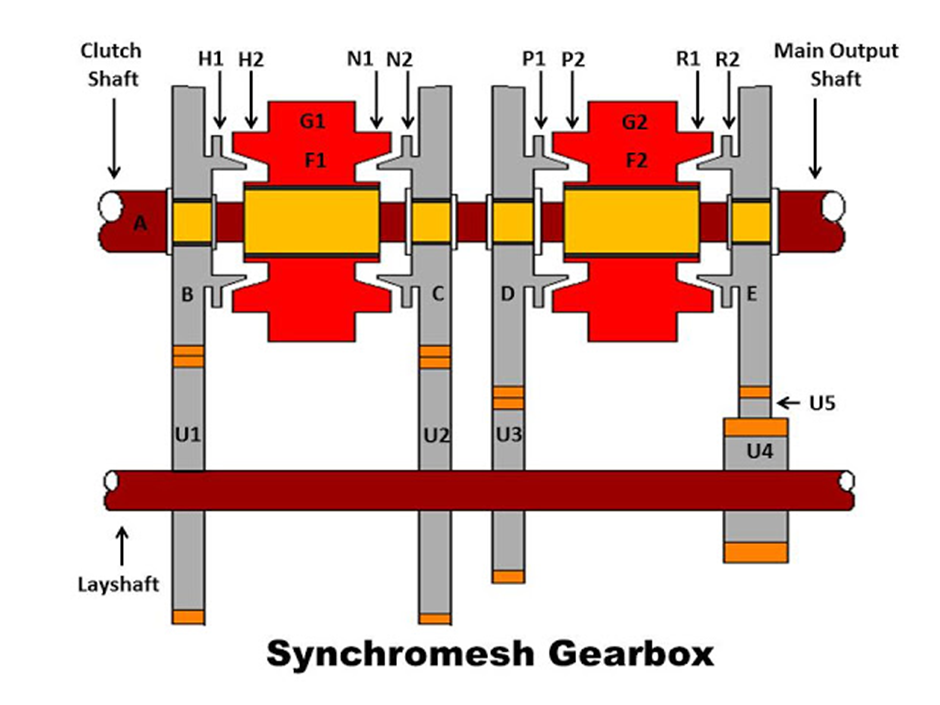

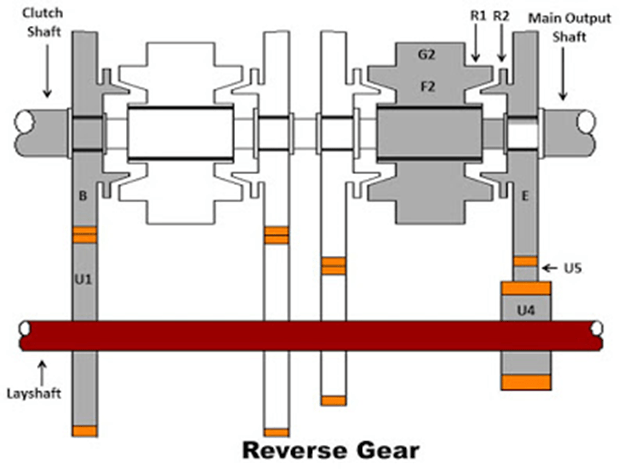

The synchronizer is positioned between two gears. So, we can use a unit for two gears. G1 and G2 are the annular elements that present the internal tooth that fits on the external teeth. F1 and F2 are the sliding elements of the main shaft. H1, H2, N1, N2, P1, P2, R1, R2 are the friction surface.

1. Main shaft gears:

A diaphragm shaft is used to connect the timing devices and gears to the output shaft. As shown in Fig. B, C, D, E are gears that can rotate freely with the appropriate gear in the secondary shaft on the main shaft in the link. Where shaft A rotates continuously, all changes in the main shaft and countershaft.

2. LayShaft Gears:

It is the intermediate shaft on which the rotational movement from the collision shaft to the final output shaft is placed on gears of appropriate size. As shown in Fig. The fixed gears on the countershaft (bearing shell) are U1, U2, U3, U4.

3. Clutch shaft:

It is the shaft used as the shaft inserted into the gearbox when the motor output is brought to the gearbox.

4. Synchronization of the cone:

There are two buttons on the side of the device to use. The first is a hollow cone and the other is the dog’s tooth ring. The gear consists of cones and teeth in contact with the synchronizer.

5. Synchronizers:

These are special gearbox equipment in synchronized boxes that have conical grooves carved into their surface, which provide frictional contact with the gear to mesh so that the main shaft, the countershaft and the speed of the embracing shaft are equalized, which, in effect, ensures smoother shifting of the gears.

6. Gear lever:

It is the shift lever operated by the driver and is used to select the appropriate gear i.e. 1, 2, 3, 4, 5 or reverse.

Working of Synchromesh Gear Box:

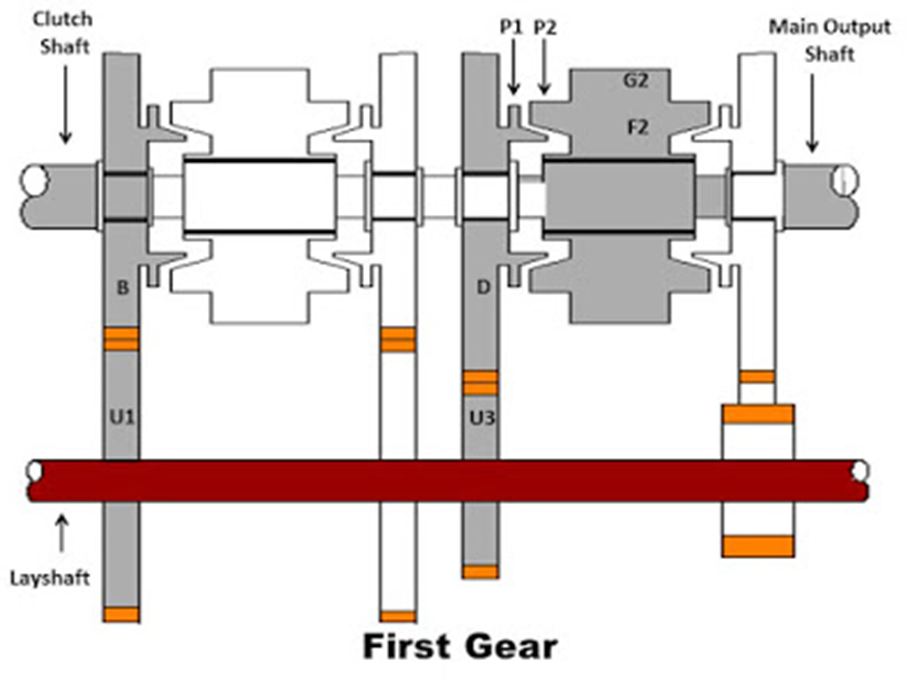

1. First gear operation: For the first gear, the ring shaft part and the sliding part, e.g. G2 and F2, move to the left until cones P1 and P2 rub. The friction is therefore proportional to its speed. Once the G2 equals its number of turns, it is moved further to the left and connects to the L2 tooth. From the clutch gear B to the countershaft gear U1 is moved by the movement. Next, the movement is transferred to the secondary shaft U3 and to the main shaft gear D. From there the movement is moved to F2, the lever and the final push to the main shaft.

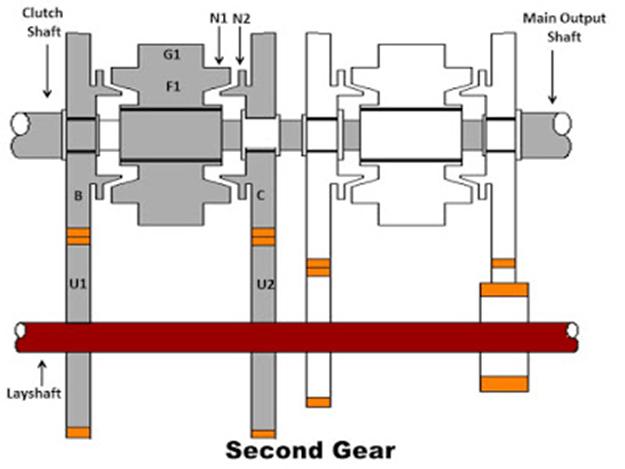

2. Second gear operation: The ring shaft for two gears and the sliding elements, ie G1 and F1, move to the right before cones N1 and N2 are frozen. Friction is therefore equal to its size. G1 is moved further to the right and in gear with the machine. The movement of gear from bucket B to load gear U1 is shifted. The motion will be passed from U1 to U2. Main shaft gear C is moved from U2. The movement is then passed to the F1 slider.

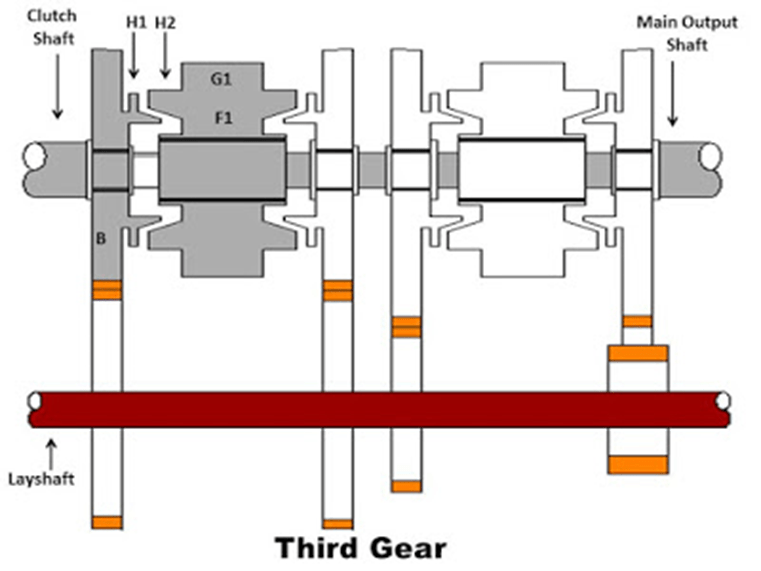

3. Working of Top Gear:

The motion is driven from cluster gear B to the sliding component F1 for top gear or direct gear. Then the key shaft from F1. You move G1 and F1 to the left.

4. Reverse operation: For reverse, the shift from clutch gear A to shaft gear U1 is transferred. The U4 laying shell fixture is moved from there and the U5 intermediate fixture is then relocated. The main shaft E, the sliding element F2, and the second shaft for the end travel from there to the other. This is achieved by moving G2 to the right. Intermediate gear leads to reverse.

Advantages of Synchromesh Gear Box:

- Smooth and quiet shifting, more suitable for cars.

- No loss of torque transmission from the engine to the drive wheels during gear changes.

- The double clutch is not necessary.

- Fewer vibrations.

- Quick shifting of gears without the risk of damaging the gears.

Disadvantages of Synchromesh Gear Box:

- It is exorbitant due to its high manufacturing cost and the number of moving parts.

- When the teeth make contact with the gear, the teeth do not engage as they rotate at different speeds, which causes a loud grinding sound as they rattle together.

- Improper handling of the equipment can easily be prone to damage. It cannot handle higher loads.

good morning, high-minded blog on fatlike loss. the like helped.

You have a very nice layout for your blog, i want it to use on my site too “