Table of Contents

1. Introduction to Dol starter:

1.1 The definition of a dol starter:

A Dol starter is a form of motor starter that is used to protect electrical motors from damage caused by sudden overloads or faults. It is a combination of a direct online starter and an overload relay. The name “Dol” is derived from the French term “démarrage à la demande”, meaning “start on demand”.

A Dol starter consists of three main components; a contactor, an overload relay, and a power supply. The contactor is a switch that is used to control the motor and prevent it from being overloaded.

The overload relay is a device that monitors the current running through the motor and trips the contactor if the current exceeds the preset limits. The power supply is a source of electricity that is used to power the contactor and the overload relay.

When the motor is switched on, the contactor closes and the power supply is connected to the motor. As the motor starts and runs, the overload relay monitors the current running through it.

If the current exceeds the preset limits, the overload relay trips the contactor and disconnects the power supply from the motor, thus protecting it from any damage caused by an overload.

The Dol starter also protects against any sudden faults, such as short circuits, by disconnecting the power supply if it detects any abnormality.

Dol starter is an effective and reliable way of protecting electrical motors from damage caused by overloads and faults. It is used in a variety of applications, such as pumps, compressors, fans, and conveyors.

1.2 The overview of the dol starter:

A Dol starter or Direct On Line starter is a type of motor starter commonly used in electrical engineering. It is used to start and stop an electric motor by supplying direct current to the motor.

This type of starter is typically used in smaller, single-phase motors up to around 5 horsepower. The Dol starter consists of two components: a contactor and an overload relay. The contactor is an electrically operated switch that is used to connect the electrical power supply to the motor.

The overload relay is a protective device that monitors the current flowing through the motor and trips the contactor if the current exceeds a predetermined level. When the start button is pressed, the contactor is energized, allowing current to flow to the motor.

When the stop button is pressed, the contactor is de-energized, cutting off power to the motor. The overload relay is present to protect the motor from damage due to overloading.

If the current flowing through the motor exceeds the predetermined level, the overload relay will trip the contactor and cut off the power supply to the motor.

The Dol starter is a simple and reliable way to start and stop electric motors. It is an economical and efficient solution for smaller motors and is well suited for applications where frequent starting and stopping of the motor is required.

2. Components of Dol starter:

2.1 The contactor:

A contactor is an electrically-controlled switch used for controlling an electrical power circuit. A contactor is typically controlled by a circuit with a higher power level than the switched circuit.

It is the main component of a Dol starter, which is an electrical starting system for an AC electric motor. The contactor is a large switch with three or more sets of contacts. It is typically composed of two main parts, an electromagnet and a set of contacts.

The contactor is energized by a control circuit, which is a circuit that is separate from the power circuit. When the control circuit is energized, the electromagnet attracts the contacts, which closes the switch.

The contractor is typically connected to the power circuit via the line and load terminals. The line terminal is connected to the power supply and the load terminal is connected to the load device, such as the motor.

When the contactor is energized, the power is transferred to the load device and the motor starts to run. The contractor also has auxiliary contacts. These contacts are used to control other circuits such as the overload relay, the timer, or the thermal overload relay.

These auxiliary contacts are used to protect the motor from overheating or overloading. The contractor is typically mounted on a panel and can be either manually operated or controlled by a push button. The contactor is the main component of the Dol starter and is the switch that controls the power circuit.

2.2 The Overload Relay:

An Overload Relay is a component of a Dol starter that helps protect the motor from damage due to excessive current. It is essentially a thermal device that operates by sensing the amount of current flowing through the motor and trips when it exceeds a pre-set limit.

The Overload Relay consists of a bimetallic strip that is heated by the current flowing through it. The temperature of the strip increases as the current increases and the strip gradually bends and eventually trips a switch when the current exceeds the pre-set limit.

The switch then trips the main contactor of the Dol starter, breaking the circuit and preventing the motor from being damaged by excessive current. Overload Relays are usually calibrated to trip at a current level slightly higher than the full load current of the motor.

This allows the motor to operate at full load for a short period of time without tripping the overload relay. This allows for short periods of increased power demand, with the motor still being protected from excessive current.

It is important to ensure that the overload relay is correctly sized for the motor that it is protecting. If the relay is too small then it may not be able to trip at the correct current level and the motor may be damaged by excessive current. If the relay is too large then it may trip unnecessarily and cause unnecessary downtime.

2.3 The Push Button:

A Dol starter consists of several components, including a push button. The push button is used to control the starting and stopping of the motor.

It is usually mounted on the front of the starter and is typically a large, red button. When the push button is pressed, the starter will energize and the motor will start. When the push button is released, the starter will de-energize and the motor will stop.

The push button can also be used to reset the starter after a fault has occurred. The push button is connected to the starter’s main contractor. When the button is pressed, it activates the contactor and energizes the starter.

The contactor then energizes the motor, allowing it to start. When the button is released, the contactor de-energizes, and the starter is reset. The push button is usually protected by a guard to prevent accidental operation.

The guard is usually a metal or plastic enclosure around the button, which must be opened before the button can be operated. Push buttons are a vital component of the Dol starter and are essential for the safe and efficient operation of the starter. They provide the operator with an easy and reliable way of starting and stopping the motor.

2.4 The Fuse:

A Fuse is an electrical safety device that is used in the components of the Dol starter. It is a sacrificial device that is used to protect the circuit against any kind of overcurrent.

The fuse is connected in series with the circuit and it is designed to melt and interrupt the flow of current in the circuit when it exceeds the rated value. When an overload or short circuit occurs, the current in the circuit increases beyond the rated value.

This causes excessive heat to develop in the fuse which causes the fuse element to melt and interrupt the flow of current in the circuit. A fuse consists of a metal strip that is surrounded by a suitable insulating material. At the center of the metal strip, there is a thin wire which is known as the fuse element.

The fuse element is designed to melt and interrupt the flow of current when the current in the circuit exceeds the rated value. The fuse is connected in series with the circuit and thus it acts as a link between the power supply and the other components in the circuit.

It is used in the components of the Dol starter to protect the circuit against any kind of overcurrent. It helps to ensure the safe functioning of the circuit and also prevents any damage to the components due to excessive current.

3. Operation of Dol starter:

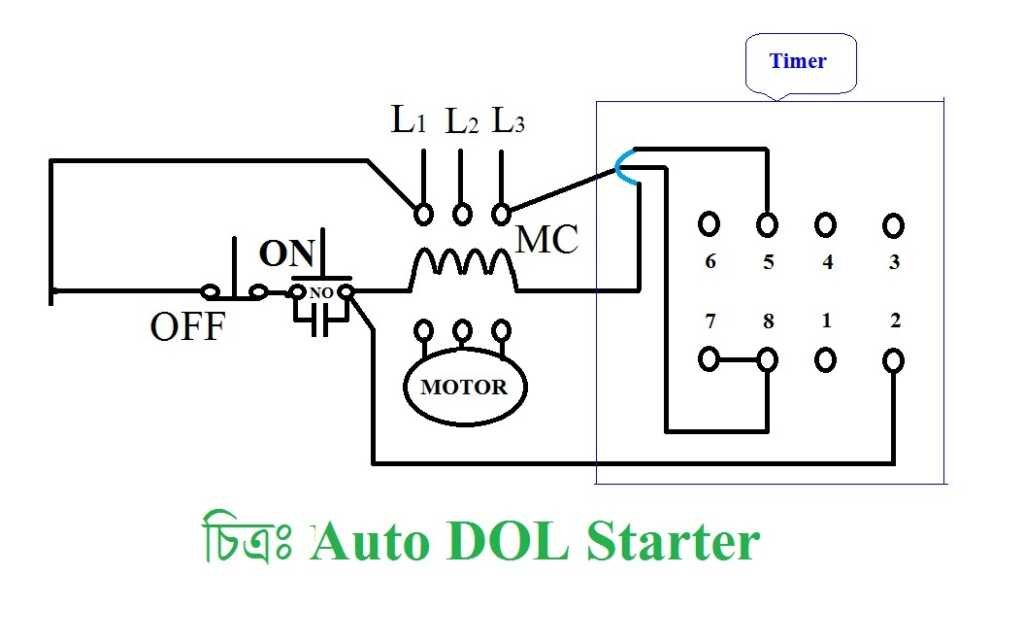

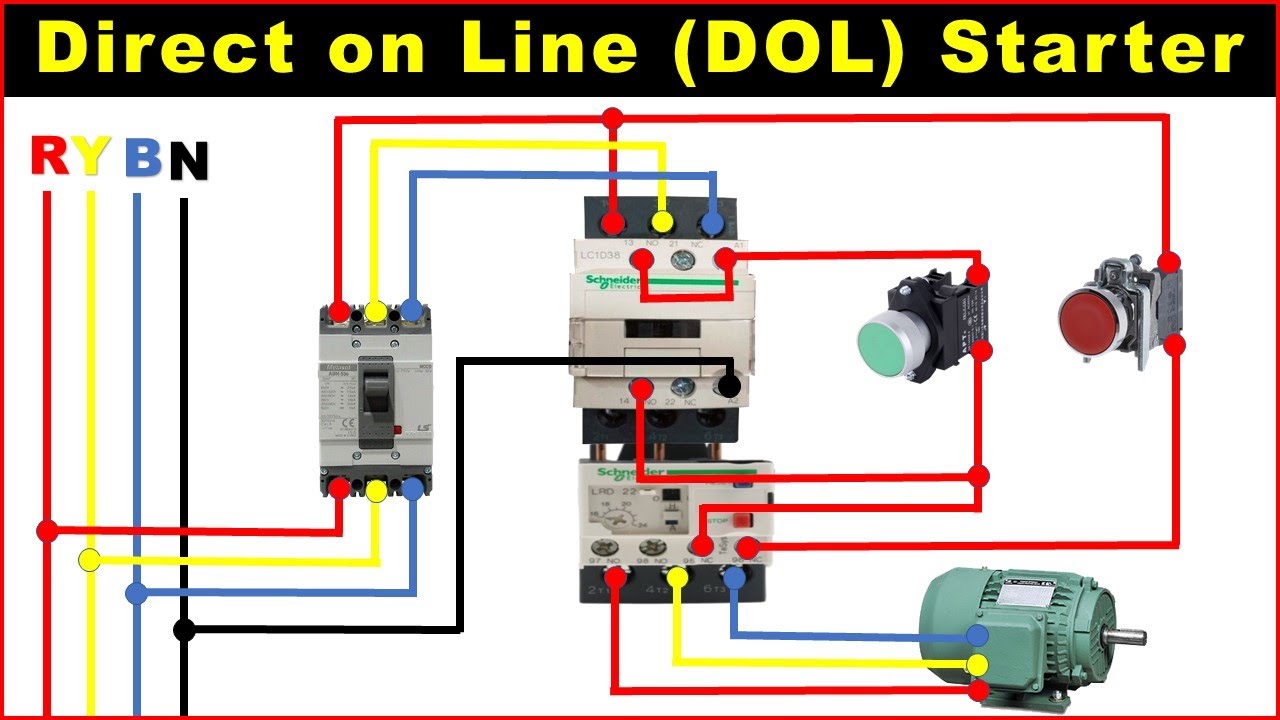

3.1 Wiring diagram:

Dol Starter wiring diagram: M1 – Motor S1 – Start Button S2 – Stop Button A1 – Contactor M1, A1 – Neutral M1, A1 – Live M1, A1 – Earth M1 – Overload A1 – Thermal Overload M1 —- S1 —- A1 —- M1 | S2 | M1 | A1 | M1 | A1 | M1 —- Thermal Overload | A1 —- Overload | M1 —- Neutral | A1 —- Neutral | M1 —- Live | A1 —- Live | M1 —- Earth | A1 —- Earth

3.2 The starting process:

A Dol starter is a motor starter device used in starting a 3-phase induction motor. It is used for motor control in low-voltage power systems. It is a combination of contactors, timers, overload relays, and fuses. The starting process of a Dol starter involves a few steps:

1. Firstly, the contactors are energized by a push button which will close the main contactors and energize the motor.

2. Once the contactors are energized, the timer or overload relay is activated. This device will monitor the current draw of the motor and will trip if it detects an overload.

3. The fuses will act as a safety device and will trip if the current draw exceeds a certain level.

4. Once the timer or overload relay has been activated, the motor will start to rotate and the contractors will be opened. This will disconnect the power supply to the motor and the motor will come to a stop.

5. Once the motor has come to a stop, the contactors will be re-energized and the motor will start again.

6. The motor will continue to run until it is switched off by the operator. These are the steps involved in the starting process of a Dol starter.

The Dol starter ensures that the motor is running safely and efficiently and will trip if an overload is detected.

3.3 The stopping process:

Dol starter is a type of motor starter that is generally used to start an induction motor. It is a combination of a direct online starter and an overload relay. It is used for connecting the motor to the supply mains.

The main components of a DOL starter are a contactor, an overload relay, and a push-button switch. The starting process of a DOL starter is very simple. When the start button is pressed, the contactor energizes and closes the main contact.

This connects the motor to the supply mains and the motor starts running. The stopping process of a DOL starter is slightly more complicated than the starting process.

When the stop button is pressed, the contactor de-energizes and opens the main contact. This disconnects the motor from the supply mains. At the same time, the overload relay trips, and the motor is isolated from the supply mains. This ensures that the motor is completely disconnected from the supply mains and the motor stops running.

The overload relay keeps the contactor de-energized until the motor is restarted. Once the motor has stopped, the contactor can be reset and the motor can be restarted by pressing the start button. This completes the stopping process of a DOL starter.

4. Applications of Dol starter:

4.1 The Motors:

A Dol starter is a starter used for controlling the starting of a three-phase induction motor. It consists of three main components: an overload relay, a contactor, and an auxiliary contactor.

The overload relay is used to protect the motor from overheating by tripping the circuit in case of excessive current. The contactor is used to switch the motor on and off, and the auxiliary contactor is used to provide a second level of control to the motor.

The Dol starter is connected to the three-phase power supply and the motor is connected in series to the contactor. When the start button is pressed, the contactor closes and the motor starts to rotate.

The current flowing through the motor is sensed by the overload relay and if it exceeds the rated current, the overload relay trips and the motor stops rotating. The auxiliary contactor is used to provide a second level of control to the motor.

It can be used to switch the motor on and off at a specific time or to reduce the speed of the motor. The Dol starter is used in many industrial applications, such as pumps, compressors, fans, and other machinery. It is a cost-effective and reliable solution for controlling the start-up and operation of three-phase induction motors.

4.2 The Lighting:

The Lighting in the Application of the Dol starter is used to provide a high degree of safety for the motor. The lighting is usually provided by fluorescent or LED lights.

The lighting is usually provided in the form of a yellow light which is switched on when the motor is in operation. The yellow light indicates that the motor is in operation and that the starter is in the engaged position.

The lighting provides an additional level of protection to the motor by alerting the user to the fact that the motor is in operation. This is especially important when the motor is in a hazardous environment where an operator may not be able to hear the motor running.

The lighting also helps to prevent the motor from overheating due to excessive use. The yellow light will indicate to the operator that the motor is in operation and should be shut down if it begins to overheat.

The lighting can also be used in the event of a power failure. In this case, the lighting will indicate to the operator that the motor has stopped working and needs to be restarted. This allows the operator to take corrective action promptly.

Finally, the lighting can be used to provide a visual warning in the event of a fault in the motor or the starter. This will alert the operator that a fault has occurred and that corrective action is needed.

4.3 The industrial Machines:

A Dol starter is an electrical control device that is used to start and stop large electric motors. It is a type of motor starter that uses a combination of direct current (DC) and alternating current (AC) to control the operation of the motor.

It works by controlling the flow of electricity to the motor, allowing it to start and stop smoothly. The Dol starter is commonly used in industrial applications, such as machine tools, pumps, compressors, and conveyor systems.

The Dol starter consists of two main components – the contactor and the overload relay. The contactor is a switch that is used to make and break the electrical connection between the motor and the power supply.

The contactor is controlled by a control circuit that is connected to the start/stop buttons or switches. When the start/stop buttons are activated, the contactor closes the connection between the motor and the power supply, allowing the motor to start.

The overload relay is used to protect the motor from overloading. It monitors the current draw of the motor and will trip when the current draw exceeds a certain limit. This helps to prevent damage to the motor and other components.

The Dol starter is used in many industrial applications, such as machine tools, pumps, compressors, and conveyor systems. It is an effective and reliable way to start and stop large electric motors. The contactor and overload relay help to ensure the safe operation of the motor and other components, reducing the risk of damage to the equipment.

5. Applications of the Dol starter:

5.1 The Advantages of a Dol starter:

A Dol starter is a type of motor starter that provides a safe and effective way to start and control the operation of an AC induction motor. It is a cost-effective, reliable, and easy-to-install solution for most motor control applications.

The Dol starter is designed to protect the motor from damage due to overload or excessive current draw. Advantages of using a Dol starter:

1. Cost-Effective: The Dol starter is an economical motor starter, as it is an easy-to-install and cost-effective solution. It is also typically easier to install and maintain than other types of motor starters, making it a great choice for those on a budget.

2. Reliability: The Dol starter is a reliable and durable motor starter, and it is designed to protect the motor from overload or excessive current draw. This helps to ensure that the motor is functioning correctly and efficiently, reducing the risk of motor failure or damage.

3. Easy-to-Install: The Dol starter is designed for easy installation and requires minimal wiring. This makes it a great choice for those who don’t have the time or skills to install more complex motor starters.

4. Versatility: The Dol starter is a versatile motor starter, as it can be used in a wide variety of motor control applications. This makes it a great choice for those who need to control various types of motors.

Overall, the Dol starter is an excellent motor starter choice for those looking for a cost-effective, reliable, and easy-to-install solution. It is designed to protect the motor from damage due to overload or excessive current draw, and its versatility makes it a great choice for a wide variety of motor control applications.

5.2 The disadvantages of the Dol starter:

(Direct On Line starter) is a type of motor starter that uses direct current to turn them on and off the motor. It is one of the most common motor starters used in industrial applications.

However, there are a few disadvantages associated with it. One of the main disadvantages of the Dol starter is that it requires a large amount of current to turn the on and off the motor. This can cause a large amount of power loss and can be dangerous in certain applications.

Additionally, the starter is limited in the size of the motor it can be used with, as it is not suitable for larger motors. Another disadvantage of the Dol starter is that it is not very efficient due to its large contactors, coils, and other components.

Due to its inefficiency, it uses more electricity than other motor starters. This can result in higher energy bills and an increased environmental impact. Lastly, the Dol starter is not suitable for applications where there is a need for precise motor control.

The starter can cause sudden motor acceleration and deceleration, which can be dangerous in certain applications. Additionally, it is not suitable for applications where the motor needs to be run at a constant speed.

Overall, the Dol starter is a reliable motor starter, but there are some drawbacks associated with it. It is unsuitable for large motors, has poor efficiency, and cannot provide precise motor control. For these reasons, it is important to evaluate the application before selecting a motor starter.

Also, read UPPCL

Comment on “Dol starter”

Comments are closed.