Table of Contents

Wind turbines attach the power of the wind and custom it to generate electricity. Merely stated, wind turbines exert the conflict of a fan. In place of using power to make wind—like a fan—wind turbines use the wind to form electricity. The wind rotates the blades, which in turn turns a generator to generate electricity. This illustration delivers a comprehensive interpretation of the confidentiality of a wind turbine, its mechanisms, and its functionality.

Anemometer:

Measures the wind speed and spreads wind speed data to the organizer.

Blades:

Lifts and rotates subsequently wind is blown over them, causation the rotor to spin. Maximum turbines have either 3 to 2 blades.

Brake:

Rests the rotor mechanically, electrically, or hydraulically, in crises.

Controller:

Flinches up the machine at wind speeds of about 8 to 16 miles per hour (mph) and closes off the machine at around 55 mph. Turbines do not function at wind speeds overhead about 55 mph because they may be spoiled by the high winds.

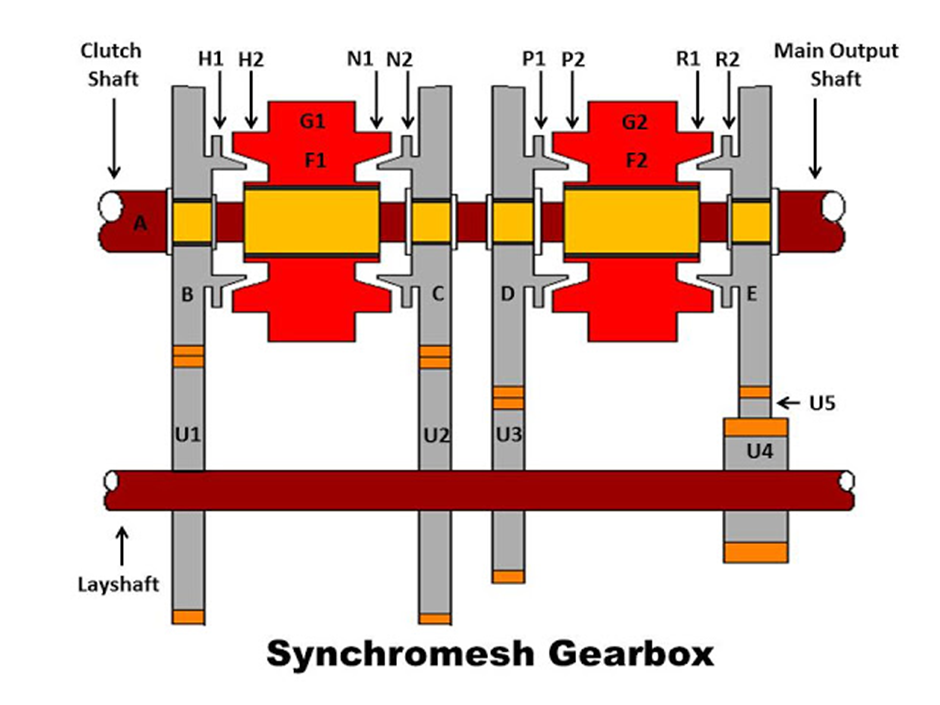

Gearbox:

Attaches the low-velocity shaft to the high-velocity shaft and upsurges the revolving rapidity from about 30-60 rotations per minute (rpm) to around 1,000-1,800 rpm; this is the rotating speed compulsory by most generators to produce electricity. The gearbox is an expensive (and heavy) part of the wind turbine and engineers are discovering “direct-drive” generators that function at lower rotational speeds and don’t want gearboxes.

Generator:

Produces 60-cycle AC energy; it is usually an off-the-shelf initiation generator.

High-speed shaft:

It energies the generator.

Low-speed shaft:

rotates the low-speed shaft at about 30-60 rpm.

Nacelle:

Sits atop the tower and contains the gear box, low- and high-velocity shafts, generator, regulator, and brake. Some nacelles are big enough for a helicopter to terrestrial on.

Pitch:

Turns (or pitches) blades out of the wind to control the rotor speed, and to keep the rotor from revolving in winds that are too high or too low to produce electricity/energy.

Rotor:

Blades and hub composed procedure of the rotor.

Tower:

Finished from tubular steel (shown here), concrete, or steel lattice. Supports the structure of the turbine. Because wind speed upsurges with height, taller towers allow turbines to imprisonment more energy and generate more electricity.

Wind direction:

Governs the design of the turbine. Upwind turbines—like the one shown here—face into the wind while downwind turbines express away.

Wind vane:

Measures wind route and interconnects with the yaw drive to position the turbine appropriately with respect to the wind.

Yaw drive:

Orients upwind turbines to keep them opposite the wind when the route changes. Downwind turbines don’t need a yaw drive since the wind manually blows the rotor gone away from it.

Yaw motor:

Influences the yaw drive.

Wind energy is on the upsurge around the world as increasingly ruthless products and ever-falling costs serve to make the technology more practicable at scale

Wind energy has arisen as one of the main renewable authority(power) sources and as such originates laden with a complex industrial process involving many key turbine components.

By the end of 2017, the worldwide capacity of the fresh energy generation method surpassed 540 gigawatts (GW), with an additional 400GW pending online in the decade between 2006 and 2016.

Temporarily, the global wind turbine processes and conservation market size augmented from $2.1billion (£1.7billion) in 2006 to $13.7billion (£10.8billion) in 2016 at a compound annual growth rate (CAGR) of additional than 20%.

Worldwide Data senior forecaster said: “The global wind power market witnessed significant growth between 2012 and 2017, with increasing wind control connected volume cumulative from 284GW in 2012 to 546GW in 2017.”

“A prodigious deal of probable exists for seaward wind installations. It is assessed that offshore wind has the potential to encounter seven times the energy mandate of Europe and IV times that of the US.

“Advanced technologies, seaward wind policy provision in some national boards, rising investor assurance, and the summary and placement of large-sized turbines for cost decrease are some of the drivers for seaward wind development globally.”

What are the numerous mechanisms of a wind turbine?

The overabundance of sub-components, which can amount up to 8,000, wanted to concept a breeze turbine including innumerable engineering processes, from metal constructing and forming to heat treating, machining, and grinding.

All of these syndicates create a product with a characteristic/typical life span of 20 years and enough generational volume to control the corresponding 750 US homelands for a year.

Four parts, though, are vivacious: The generator, nacelle, tower, and blades.

Generator

The generators used in contemporary wind turbines use the change in electric charge to generate a change in voltage, which acts as the pouring force behind the succeeding electrical current.

This current is then conceded through power lines for circulation, powering the turbine’s accompanying grid.

Nacelle

The nacelle dynasties a wind turbine’s generator, and is frequently regularly manufactured as either gear-driven or direct drive.

A wind turbine’s nacelle houses a gathering of sub-components (Credit: Fabricators & Manufacturers Connotation)

The former can encompass a case as heavy as 150 tonnes, whereas the latter encompasses a rotor hub which straight determinations the maker deprived of the need for a gear train preparation.

Tower

Wind turbine towers are formed at various different altitudes, with the average being unevenly 50m and the highest surpassing 200m.

They are frequently coated with a zinc-based appearance and epoxy and urethane coatings to provide electromagnetic resistance.

The average weight typically exceeds 40 tonnes, and a tower can often explain for additional than 10% of the complete cost of a wind turbine.

Rotor Blades

Wind turbine blades can grasp speeds an extra 160 miles per hour when in process and therefore need robust building.

The constituent mainly encompasses wood, fiberglass, resin, and carbon, but the container hosts more than 100 layers of physical once complete.

The world’s major wind turbine: The Haliade-X

US corporation General Electric (GE) is currently emerging the $400m (£315m) Haliade-X, which, organized in 2021, will shadow the current greatest container for the foremost wind turbine in the world.

The creation is set to house 12MW of volume and will reach 260 meters overhead sea level, higher than the Eiffel Tower, while each blade will stretch 107 meters, longer than a football pitch.

GE’s engineering and creation expansion leader Vincent Schellings said: “A higher capacity factor makes Haliade-X less subtle to wind speed differences, meaning better expectedness and the ability to generate more power at low wind speeds, and can detention more annual energy production than any other seaward wind turbine.

General Electric’s forthcoming Haliade-X offshore wind turbine is 260 meters giant, creating it taller than the London Eye (135 meters) and the Statue of Liberty (93 meters) mutual (GE).

“The quantities of a wind turbine of this magnitude will be a first time in numerous ways, so we are getting prepared for that.

“With development come challenges, exactly the challenge to compete with unfashionable sources of power collection, such as natural gas and coal, on a non-subsidized basis in auctions and request for proposals [RFPs] everywhere in the world.”

“The extension of the Haliade-X wind turbine will reimbursement to seaward challenges like diminishing the cost of energy in upcoming projects, while also contributory to the industry’s growing motion.”

Comment on “Basic components of wind energy Turbine”