Table of Contents

Introduction:

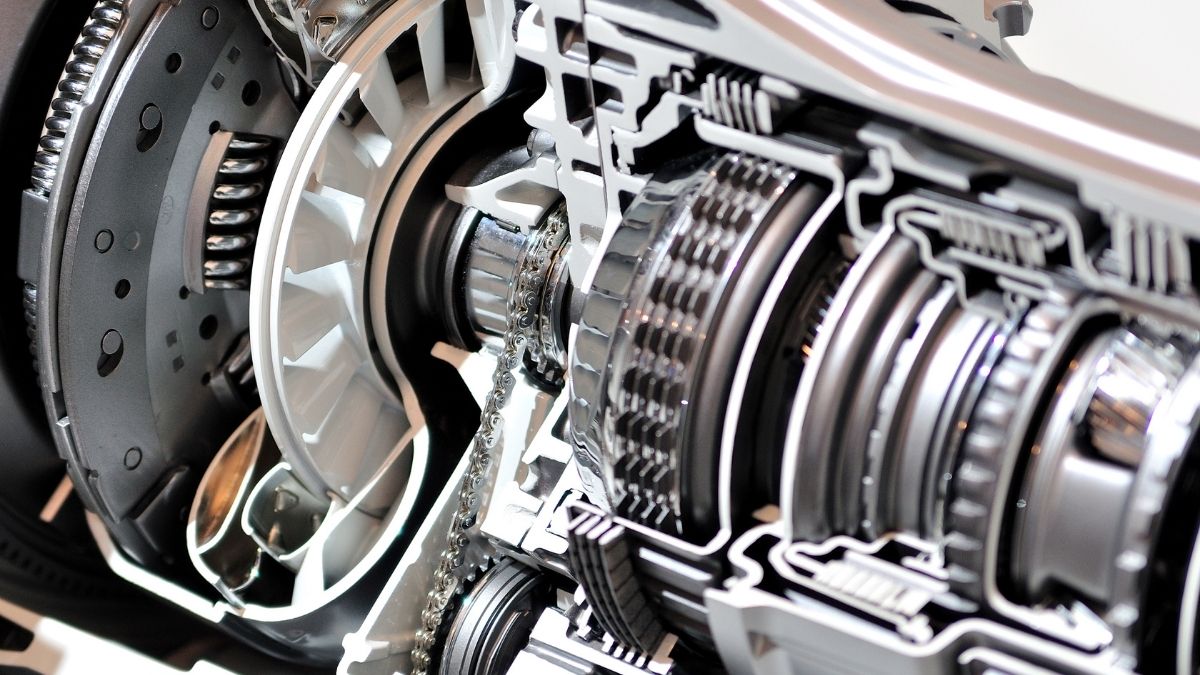

A clutch plate is an essential component of a manual transmission system in a vehicle. The clutch plate is responsible for connecting the engine to the transmission and allowing the driver to engage or disengage the power from the engine to the wheels.

What is a Clutch Plate?

A clutch plate is a flat disc made of friction material that is inserted between the flywheel and the pressure plate. The flywheel is connected to the engine, while the pressure plate is connected to the transmission. The clutch plate is responsible for transmitting the torque from the engine to the transmission when the clutch is engaged.

A clutch plate is commonly used in manual transmission vehicles such as cars, trucks, and motorcycles. The clutch plate is used to engage and disengage the power from the engine to the wheels. This is important when the vehicle is stopped, starting from a standstill, or changing gears.

Types of Clutch Plates:

1. Single Plate Clutch:

A single-plate clutch is the simplest type of clutch system used in vehicles. It consists of a clutch plate, a pressure plate, and a release bearing. The clutch plate is attached to the engine’s flywheel, while the pressure plate is attached to the transmission’s input shaft. When the clutch pedal is pressed, the release bearing pushes against the pressure plate, which disengages the clutch plate from the flywheel.

This stops the power transmission from the engine to the transmission, allowing the driver to change gears or come to a stop. When the clutch pedal is released, the release bearing disengages from the pressure plate, allowing the clutch plate to engage with the flywheel and transmit power from the engine to the transmission.

2. Multi-Plate Clutch:

A multi-plate clutch is a type of clutch system used in high-performance vehicles. It consists of multiple clutch plates, pressure plates, and a release bearing. The clutch plates are stacked together and alternately connected to the flywheel and the pressure plate. When the clutch pedal is pressed, the release bearing pushes against the pressure plate, disengaging the clutch plates from the flywheel.

This stops the power transmission from the engine to the transmission, allowing the driver to change gears or come to a stop. When the clutch pedal is released, the release bearing disengages from the pressure plate, allowing the clutch plates to engage with the flywheel and transmit power from the engine to the transmission.

3. Cone Clutch:

A cone clutch is a type of clutch system used in industrial and agricultural machinery. It consists of two cone-shaped surfaces, one attached to the flywheel and the other attached to the transmission’s input shaft. When the clutch pedal is pressed, the cone-shaped surfaces move closer to each other, allowing the transmission of power from the engine to the transmission. When the clutch pedal is released, the cone-shaped surfaces move apart, disengaging the power transmission.

4. Centrifugal Clutch:

A centrifugal clutch is a type of clutch system used in small engines such as lawnmowers and chainsaws. It consists of a clutch shoe assembly and a clutch drum. The clutch shoe assembly is attached to the engine’s output shaft, while the clutch drum is attached to the transmission’s input shaft.

When the engine is running, the centrifugal force causes the clutch shoes to expand and engage with the clutch drum, transmitting power from the engine to the transmission. When the engine is idling, the clutch shoes contract, disengaging the power transmission.

Working of Clutch

When the driver presses the clutch pedal, the clutch plate is disengaged from the pressure plate. This separates the engine’s power from the transmission, allowing the driver to shift gears. When the driver releases the clutch pedal, the pressure plate applies pressure to the clutch plate, engaging the clutch. This connects the engine’s power to the transmission, and the vehicle moves forward.

In a friction clutch, the clutch plate and pressure plate are covered with friction material, usually made of asbestos, to increase their grip. However, due to the health hazards associated with asbestos, newer materials like organic and ceramic are now used.

Maintaining the clutch plate

Maintaining the clutch plate is crucial to ensure that it functions correctly and lasts longer. Here are some tips for maintaining the clutch plate:

1. Avoid resting your foot on the clutch pedal while driving.

2. Ensure that the clutch is fully disengaged before shifting gears.

3. Avoid riding the clutch while driving.

4. Regularly check the clutch fluid level and replace it when necessary.

5. Avoid abrupt starts and stops while driving.

6. Have the clutch inspected by a professional mechanic regularly.

Applications of Clutch

The clutch is a vital component in any vehicle with a manual transmission. It enables the driver to control the power transmitted from the engine to the wheels. The clutch is also used in industrial machinery, such as power presses, where it is used to engage or disengage the load.

Also, read the welding machine

Comments on “What is a Clutch? Its Types, Applications & Working”

Comments are closed.