Table of Contents

Components of the internal combustion engine: An internal combustion engine is the source of “power” in a car. Internal combustion engines can be broadly classified based on their operation, number of cylinders, and the fuel used. Depending on your operation, the engine can be either two-stroke or four-stroke. In two-stroke engines, the work cycle is completed in one revolution (360°) of the crankshaft. In the four-stroke engine, the work cycle is completed in two rotations (720°) of the crankshaft. Four-stroke engines are used in cars. As for the classification based on the number of cylinders, engines can be single-cylinder or multi-cylinder.

A multi-cylinder engine is best suited for cars. Conventionally, engines use either gasoline or diesel fuel and are therefore classified as either gasoline or diesel engines. Lately, some alternative fuels such as compressed natural gas, hydrogen, etc., have also been used. Few hybrid cars with two engines are also being developed. These cars are equipped with battery-powered electric motors along with conventional motors.

IC ENGINE COMPONENTS:

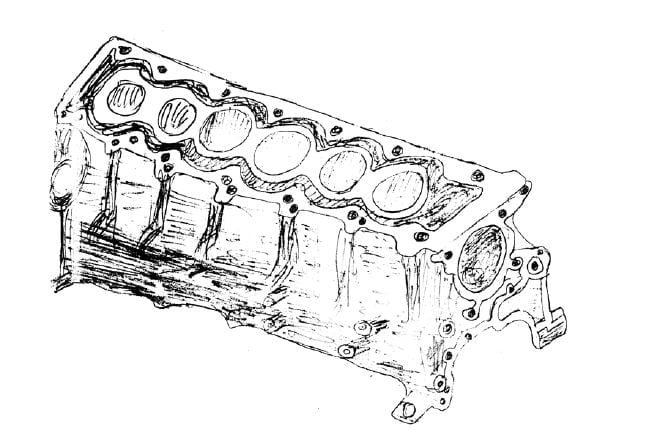

Cylinder Block:

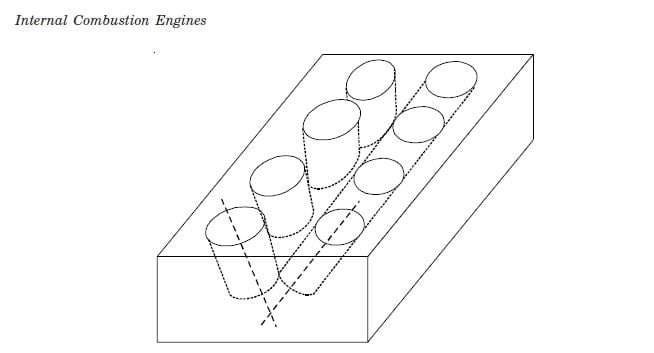

This is the main component of the engine. It forms the central part of the engine. At its lower end is the crankcase and at its upper end is the cylinder head. The block has cylinders in which the pistons slide up and down. The number of cylinders can vary from 4, 6, 8 or sometimes even more, depending on the size of the engine and the power required. These cylinders can be in a single row or can be arranged to form two banks. These benches are at an angle to form a V.

Engines with all cylinders in-line are known as in-line engines and those where the cylinders form a V are known as V-engines. Cylinder blocks are also supplied with coolant through. Hot, high-pressure gases push the piston down into the cylinder. This causes maximum heating of the cylinder block due to unused thermal energy.

The coolant flowing through the passage removes this heat. Most cylinder blocks are made by casting using cast iron. Sometimes iron mixed with nickel or chrome is also used. Aluminium alloy is also used to cast the cylinder block.

Crank Case (Components of the internal combustion engine):

It forms the bottom of the engine. It has crankshaft capability. The crankshaft is a long, straight piece of metal on a vehicle that connects the engine to the wheels and helps convert the engine’s power into motion. It rests at its ends on the walls of the crankcase.

The crankcase is provided to support the crankshaft. On some engines where the crankshaft is very long, it is also supported in the middle and the crankcase has a provision to provide support. In addition, the crankcase acts as a reservoir for lubricating oil. Generally, the upper part of the crankcase is an integral part of the cylinder block, and the lower part of the crankcase is bolted to it. Aluminium alloy is the most suitable material for the crankcase. It is lightweight and has good thermal conductivity. Earlier cast iron was also used as a material for the crankcase.

Cylinder Head:

The head is capable of being fixed as an in-and-out model. This also forms the top of the acquisition chamber. The camera approaches different paths. All forms of effective fuel production.

The cylinder head material is cast iron or aluminium alloy. The plant is made so that various components can be installed without any problem.

To avoid noise and expensive cars, the heads of the cars are covered. The cover is made of three-layer foil. The two metallic outer layers and the appearance are plastic. This plastic layer does not allow the transmission of noise and vibrations from the engine.

In the wedge-shaped combined mixing chamber, the turbulence of the flare is increased. The chamber of diesel or bottle-shaped engines is prone to turbulence and is particularly suitable for diesel or turbocharged engines. In the relatively slow hemisphere, the call option is

Piston (Components of the internal combustion engine):

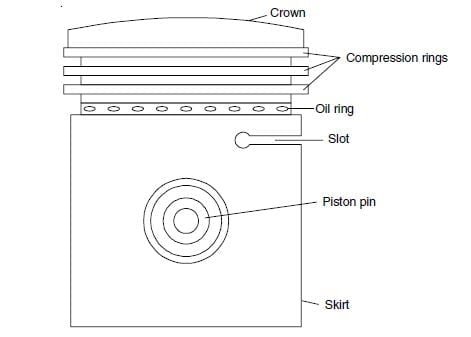

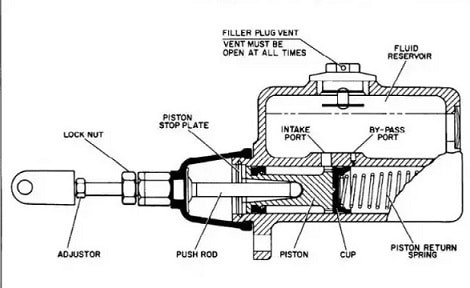

The piston moves inside the cylinder and has a reciprocal motion. It is hermetic and does not allow the escape of charge and hot gases with the help of rings that are part of the piston ring set. It also transmits the impact produced by gases at high temperatures and pressure. It accommodates the small end of the connecting rod and receives lateral thrust due to the obliquity of the connecting rod.

The top of the piston is known as the crown. Piston rings and piston pins are integral parts of the piston assembly. The bottom of the piston is known as the skirt. A groove is provided in the piston. The groove accommodates the expansion of the piston material when hot. This helps reduce the clearance between the skirt and the cylinder when cold. When hot, the groove accommodates the expansion of the piston material.

Aluminium alloy is the most commonly used material for pistons. The alloy contains approximately 12% silicon, which has a lower coefficient of expansion compared to aluminium and cast iron. The addition of phosphorus increases the resistance to fatigue. The addition of cobalt and chrome further reduces the coefficient of expansion, making the piston suitable for use where proper cooling is not possible.

Piston rings and piston pins are the components of the piston sub-assembly. The outer surface of the piston ring is in close contact with the inner surface of the cylinder. The ring becomes a perfect circle in the cylinder. In the disassembled state, when left free, it is slightly oval. The rings are known as compression rings as they prevent the escape of hot combustion gases during expansion. In addition to compression rings, there are oil rings intended for the lubrication of the piston sub-assembly, mainly in large engines.

Connecting Rod:

As its name implies, it connects the piston with the crankshaft. It is an end that holds the piston pin and is known as a small end. Another end, known as the large end, holds the crank pin. It can have circular, rectangular, I, T or even H sections. It is forged steel and is highly polished to improve strength. It has a passage for transferring the lubricating oil from the larger end bearing (crankshaft pin) to the larger end bearing (piston pin).

Crankshaft:

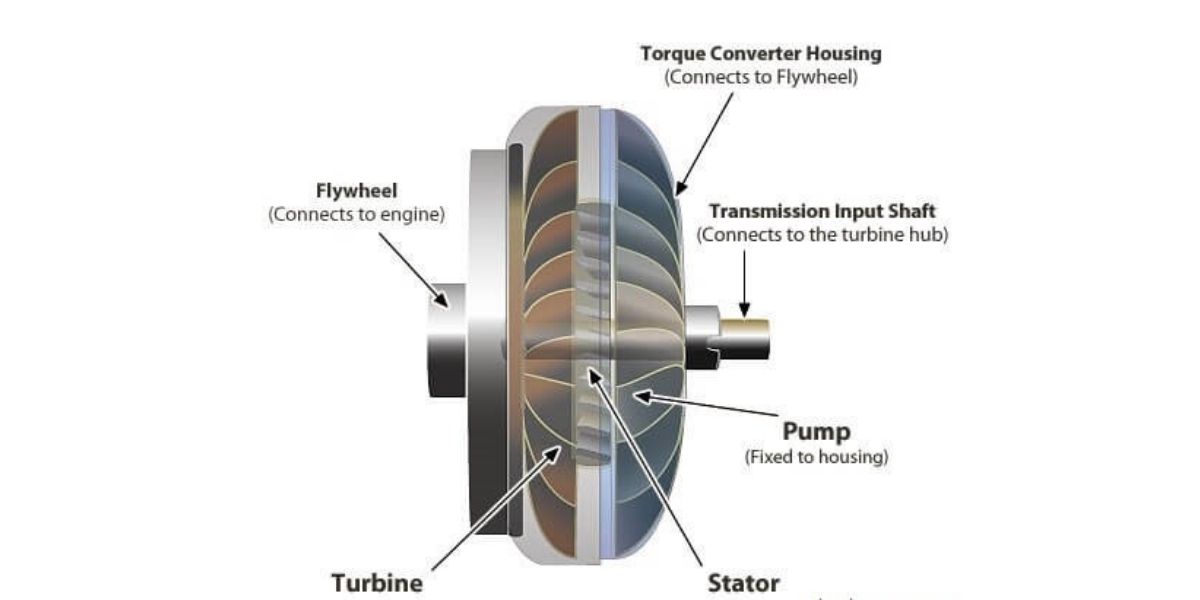

The crankshaft requires detailed study as it is an important engine component used in a car. Multi-cylinder engines are used in cars. The crankshaft of a multi-cylinder engine, due to its shape and load, requires special attention from designers.

Basically, a crankshaft converts the reciprocating motion of the pistons into a rotary motion. The simple machine principle known as wheel and axle is applied. The crankshaft is made of forged or cast steel and is machined to provide proper journals for the connecting rod and main bearings. The crankshaft parts from the main bearing to the connecting rod bearings are called crankshaft arms or cheeks.

The length of the crank arm determines the engine’s stroke. From the centre of the main bearing journal to the centre of the connecting rod, the journal is half the engine travel. The part of the crankshaft that is inside the connecting rod bearings is called the crankshaft journal and those that are inside the main bearings are called the main journal.

The number of main bearings varies depending on the engine design and the number of cylinders. There must be at least two, i.e. one at the front and one at the rear of the crankshaft. More main bearings mean less chance of vibration and distortion from a given size crankshaft. To minimize vibration in the engine, the crankshaft and flywheel are balanced separately and are usually balance tested when mounted together.

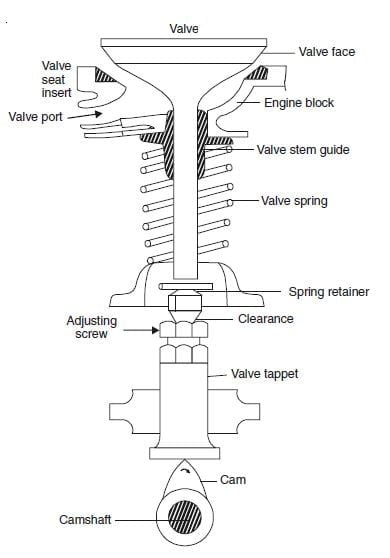

Valve and Valve Mechanism:

There are two commonly used valves, one intake/inlet and one exhaust. The valve movement is driven by an eccentric projection called a cam that moves on a rotating axis: the camshaft. As the camshaft rotates, the cam lifts the valve, but its closure is dependent on the spring. These springs must have considerable tension to close immediately and prevent them from popping off the cams, especially at high engine speeds.

Clearance is provided between the valve tappet and valve stem so that expansion due to the heat generated in the engine does not adversely affect operation. The clearance is more at the exhaust valve since it is at a higher temperature. The clearance can be adjusted with the help of a provided nut. Improved systems were also designed, such as a hydraulic valve lifter and an eccentric swingarm. These automatically compensate for the difference in free space.

Camshaft:

It is a long straight piece of metal with a cam that joins machine parts together, especially in a vehicle. It is responsible for opening/closing the valve. It carries a cam for each valve to be operated and the valve lift is determined by the distance the tip of the cam projects above the rounded base of the cam. The camshaft is driven from the crankshaft by a pair of meshing gears or by a pair of sprockets connected by a chain. The camshaft rotates at half the speed of the crankshaft, as the valves open only once in a complete cycle that requires two revolutions of the crankshaft in a 4-stroke engine.

Experience stress-free travel with Airport Transfer DFW. Our Dallas/Fort Worth International Airport transportation service offers a fleet of luxurious sedans, SUVs, and vans, driven by experienced chauffeurs. Whether it’s an early morning or late-night flight, our 24/7 availability ensures timely arrivals. Enjoy transparent pricing, professional service, and a seamless journey to your destination. Your travel, our priority.