Table of Contents

An overview:

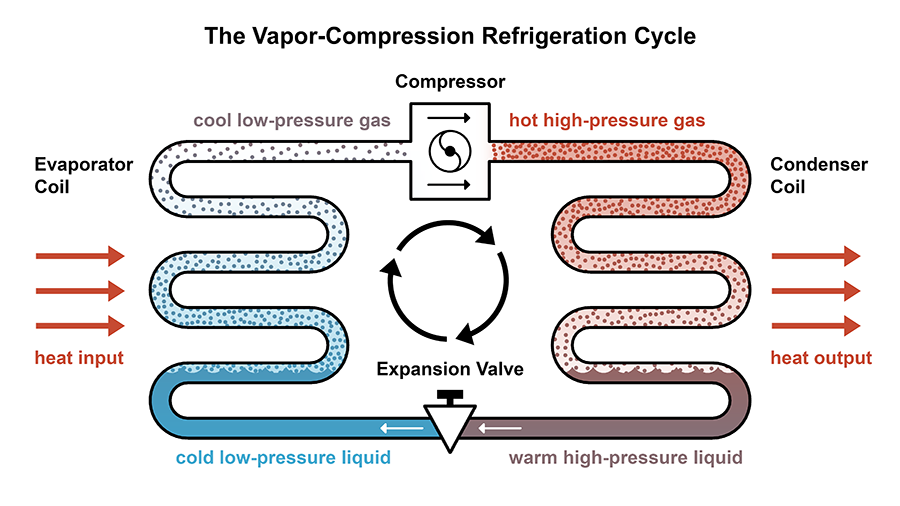

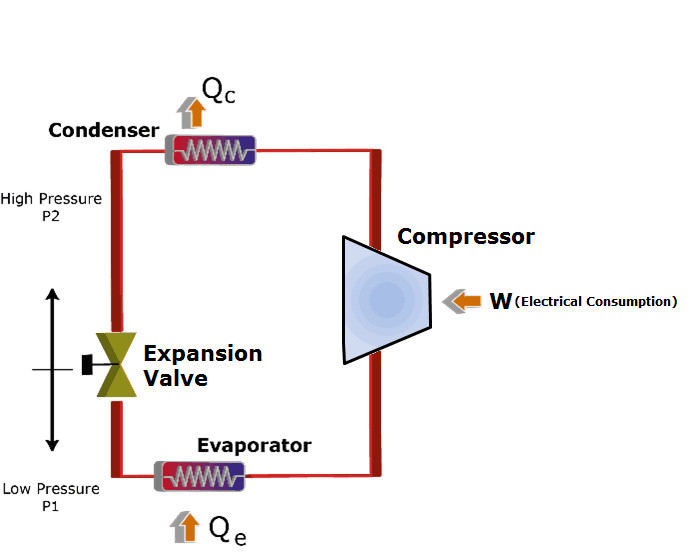

The refrigeration cycle is a simple yet incredibly smart and useful process. In its simplest form, the refrigeration cycle consists of just 4 introductory factors to complete the circuit

A compressor.

A condenser.

An expansion device.

An evaporator.

That is it. Well, that is it, we also need a coolant to circulate inside the circuit.

As its name suggests, the refrigeration process is a cycle. We start at the compressor, go through the condenser, also the restriction, also the evaporator, and eventually back to the compressor where the cycle starts again.

Components of the refrigeration cycle:

The 4 main components of the refrigeration cycle.

We have all been there. You walk in on a hot day and, luckily, you are saluted by a wall of fresh air. Well, you have the refrigeration cycle to thank for that relief. While there are dozens of heating and cooling styles, the introductory function remains the same and is used in some form in numerous diligence and processes. But how does it work? This post will answer that question by describing the main factors of a standard cooling circle and the functions of each.

In simple terms, the charge of a refrigeration cycle is the immersion and rejection of heat. As any HVAC educator will tell you( emphatically), you can not cool it, you can only remove the heat. The refrigeration cycle occasionally called the heat pump cycle, is a means of moving heat down from the area you want to cool. This is done by manipulating the pressure of the working coolant( air, water, synthetic coolants.) through a contraction and expansion cycle.

That is not each, of course, but that is the introductory idea. Now, let’s get into the platoon that helps make this work. There are clearly other factors to utmost circles, but utmost would agree that the four abecedarian rudiments of an introductory circle are as follows

2.1 The compressor.

2.2 The condenser.

2.3 The expansion device.

2.4 The evaporator.

compressor:

Compression is the first step in the refrigeration cycle, and a compressor is a device that increases the pressure of the working gas. Refrigerant enters the compressor as a low-pressure, low- temperature gas and exits the compressor as a high-pressure, high-temperature gas.

what are the types of compressors?

Compression can be achieved through a number of different mechanical processes, and because of this, colorful compressor designs are used in HVAC and refrigeration moments. There are other exemplifications, but some popular options are

- Indispensable compressors

- Scroll compressors

- Rotary compressors

The condenser:

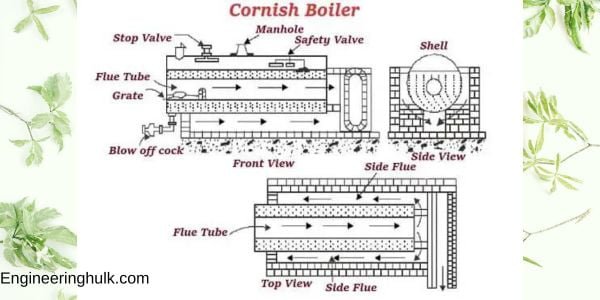

The condenser, or condenser coil, is one of two types of heat exchangers used in an introductory refrigeration circuit. This element is fed high-temperature, high-pressure wracked refrigerant from the compressor.

The condenser excerpts toast from the hot refrigerant gas vapor until it condenses into an impregnated liquid state, also known as condensation. After condensation, the refrigerant is a liquid at high pressure and low temperature, at which point it’s directed to the circuit expansion device.

expansion device:

These factors come in many different designs. Popular configurations include fixed perforations, thermostatic expansion faucets( TXVs) or thermal expansion faucets( pictured over), and the more advanced electronic expansion faucets( EEVs). But anyhow of the configuration, the job of the system expansion device is the same- to produce a pressure drop after the refrigerant leaves the condenser.

This pressure drop will beget some of that coolant to boil fleetly, creating a two-phase admixture. This rapid-fire phase change is called flashing and helps prepare the coming piece of outfit in the circuit, the evaporator, to perform its intended function.

The evaporator:

The evaporator is the alternate heat exchanger in a standard refrigeration circuit and, like the condenser, is named after its introductory function. It serves as the” end of business” of a refrigeration cycle, as it does what we anticipate an air conditioner to absorb heat.

and, like the condenser, is named after its introductory function. It serves as the” end of business” of a refrigeration cycle, as it does what we anticipate an air conditioner to absorb heat.

This happens when refrigerant enters the evaporator at a low temperature, a low-pressure liquid, and an addict forces air through the evaporator fins, cooling the absorbed air.

that coolants turn red when they pass through an air exertion system. But this isn’t the case. Rather, they’re extremely cold. For illustration, a refrigerant, R- 410, has a boiling point of roughly 55 °F( or-48.5 °C), although this changes as the pressure of the refrigerant changes.

That is why you do not need a whole network of pipes to convert refrigerant between liquid and gas; the ambient temperature itself is significantly above the boiling point of the coolant. The colder a refrigerant is, the further heat it can absorb and the lesser its capability to cool in an air exertion system.

Sub cooling :

A capillary tube/ expansion device is designed to control the quantum of liquid refrigerant passing through the evaporator. However, the system won’t work as it should, If refrigerant gas enters the device/ pipe. To ensure that only coolant reaches the element, the coolant is subcooled. In short, the refrigerant is significantly colder than the boiling point, to ensure that all the refrigerant is in a liquid state.

For illustration, if the coolant must be below 100 °F to be a liquid, the coolant can cool down to 85 °F. This ensures that there are no accidental pockets of refrigerant above 100 °F that could help the system from performing duly.

Overheating:

Overheating is analogous. A compressor is installed to compress the refrigerant gas. It can be damaged if the coolant gets outside. thus, the gas is heated significantly.

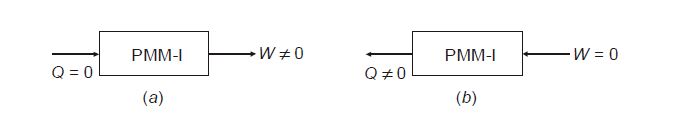

Comment on “A Refrigeration cycle operates between a condenser temperature of + 27”

Comments are closed.